Annular ingot casting equipment and casting method thereof

A casting equipment, ring-shaped technology, applied in the direction of casting equipment, ingot casting workshop, casting workshop, etc., can solve the problems of shrinkage cavity, air bubbles, thermal stress, porosity, etc., and achieve high uniformity, internal grain refinement, microstructure The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

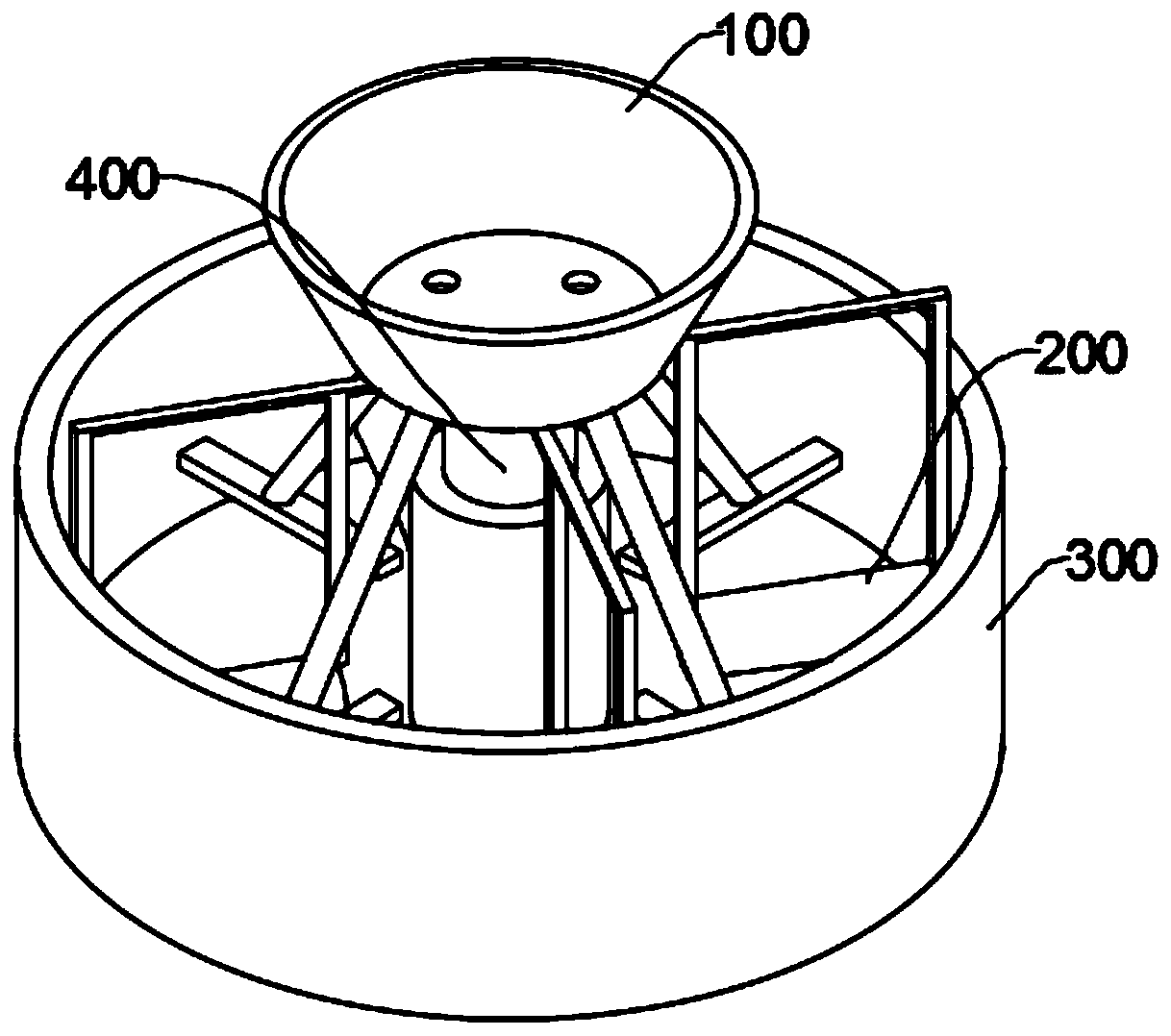

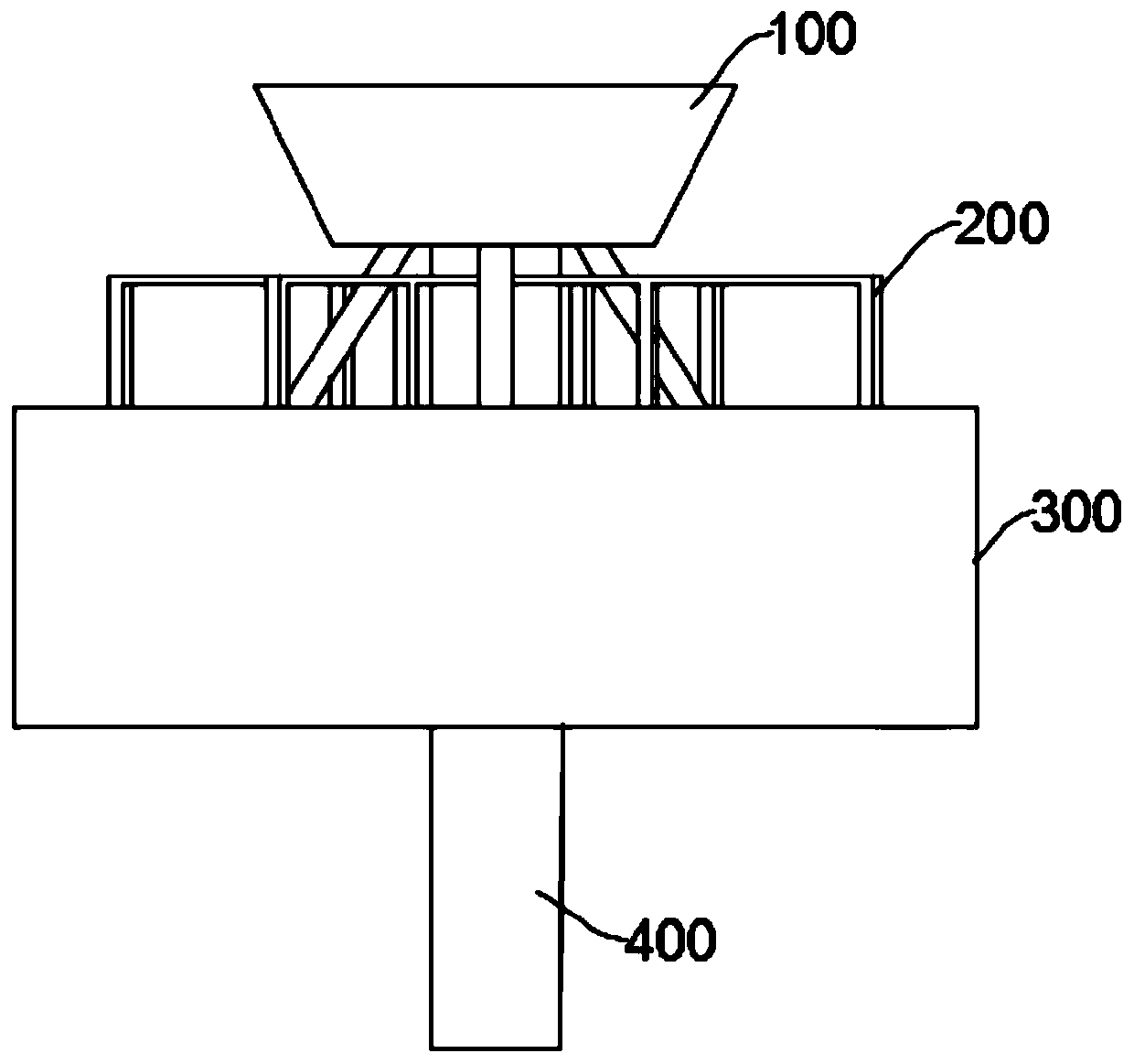

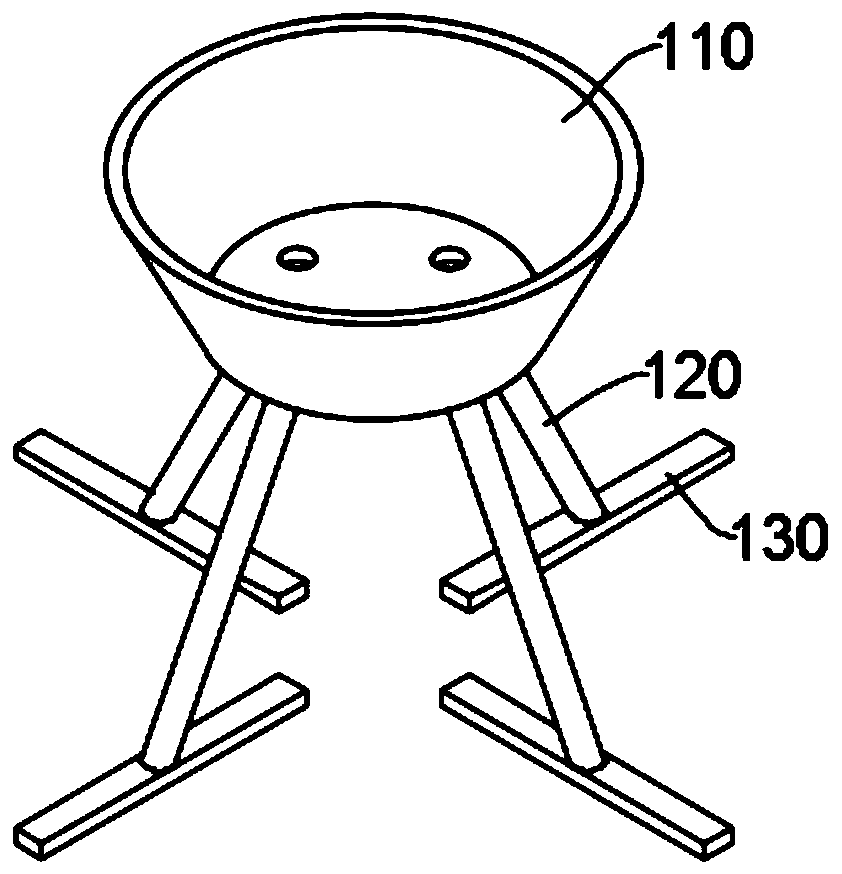

[0041] Such as figure 1 and figure 2 As shown, a circular ingot casting equipment is used for casting a large cylindrical ingot, which mainly includes a gating system 100 , a rolling system 200 , a casting mold 300 and a support column 400 . Wherein, the support column 400 is arranged vertically, and its bottom end is fixedly connected on the ground or corresponding equipment; the pouring system 100 is used for injecting the melt into the casting mold 300, and the casting mold 300 is used for forming the ingot; the rolling system 300 is used for When the melt solidifies into a casting, the upper end of the ingot is flattened and rolled. The specific structure and working principle of the device will be described in detail below.

[0042] Such as Figure 6 As shown, a section of the middle part of the support column 400 has a thread for the installation of the casting mold 300. The upper and lower ends of the thread have a certain distance from the upper and lower ends of the...

Embodiment 2

[0049] A kind of annular ingot casting method, adopts a kind of annular ingot casting equipment of embodiment 1, and its steps are:

[0050] 1. Before starting casting, adjust the height of the casting mold 300 on the support column 400 so that the bottom of the casting mold 300 is close to the bottom of the roll 210 and the flow distributor 130 but maintain a small gap, which is 6 mm in this embodiment. After adjustment, the casting system 100 works to add melt to the tundish, and the melt spreads evenly in the mold cavity 330 through the shroud and flow distributor 130, and is cooled and solidified in the mold cavity 330 to form a casting with a certain height. At the same time, the casting mold 300 is driven to rotate by the rotating device, and is lifted and lowered on the supporting column 400 under the thread cooperation between the supporting column 400 and the inner ring of the casting mold 300 . The rollers 210 of the rolling system 200 level the melt that has not bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com