Automatic grinding device for bearing outer rings and grinding method

A technology of bearing outer ring and transmission rod, which is applied in the field of bearing processing, can solve problems such as difficult and efficient grinding, debris falling into one another, and affecting processing quality, etc., to achieve the effect of close fit for transportation and strong synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

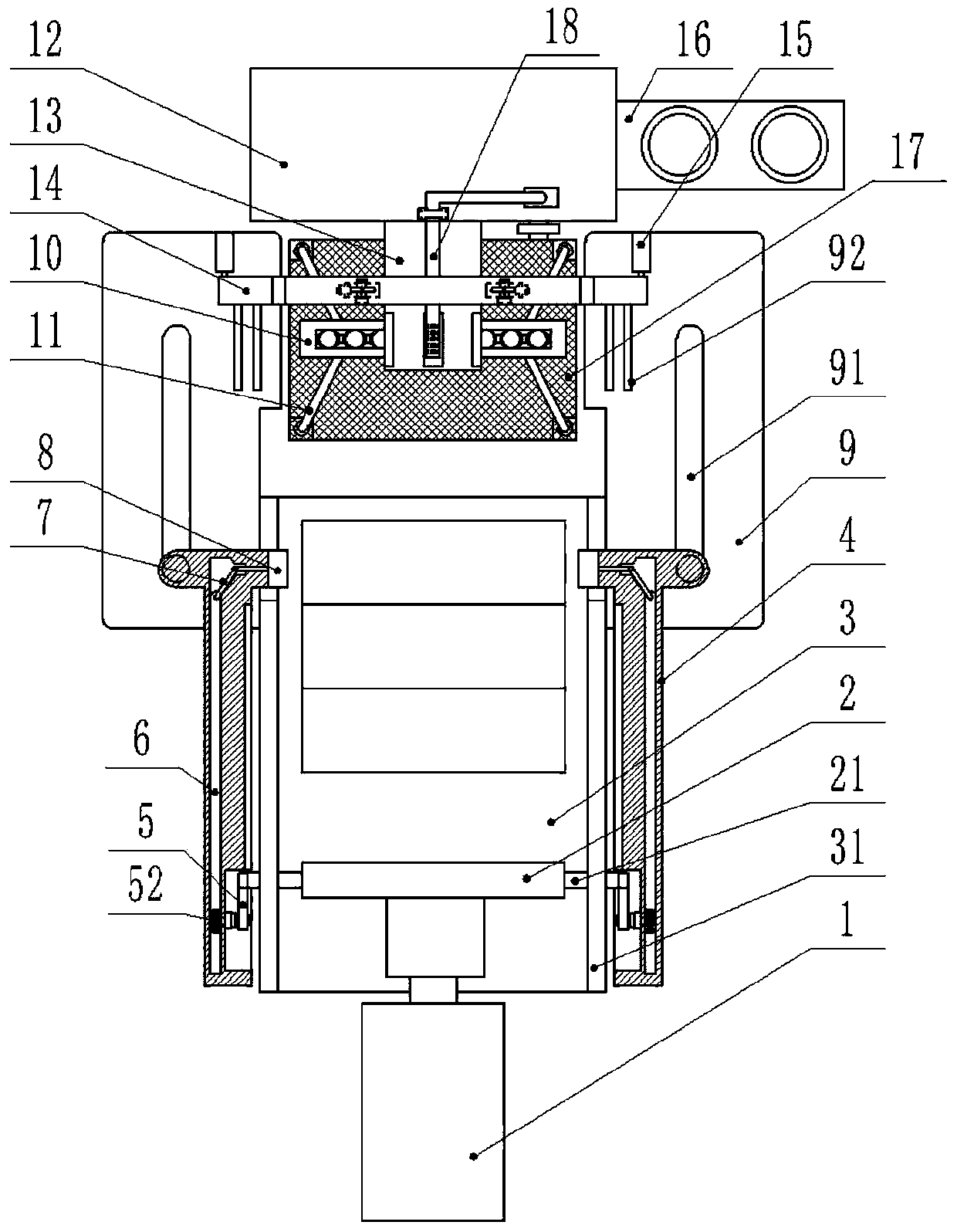

[0072] An automatic grinding device for a bearing outer ring, wherein, such as figure 1 As shown, it includes: a first telescopic structure 1 , a push plate 2 , a transfer table 3 , a synchronous gripper 4 , a positioning table 9 , a support assistant 10 , and a driving gripper 13 .

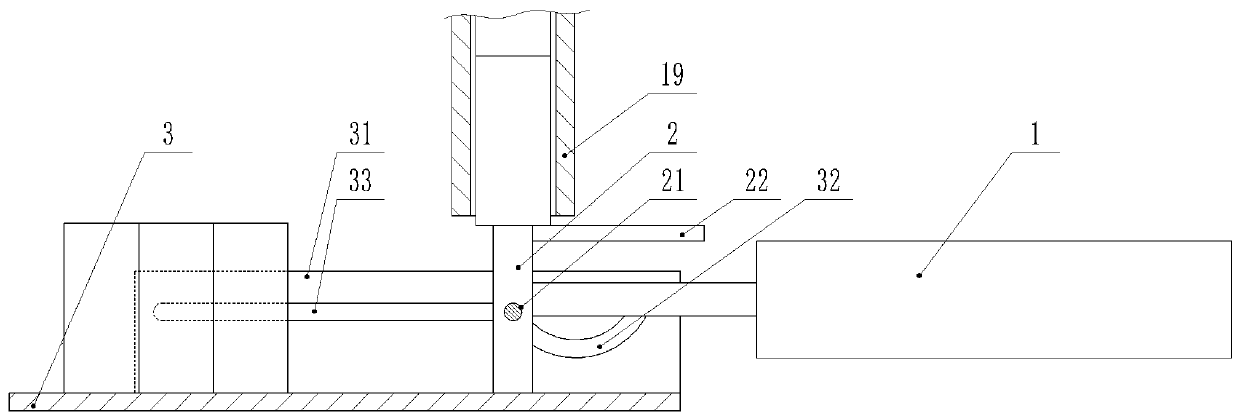

[0073] The pusher plate 2 is connected to the first telescopic structure 1, and there are transmission rods 21 on both sides of the pusher plate 2, and the drive rods 21 can move up and down on the side ends of the pusher plate 2.

[0074] like figure 2 As shown, the transmission table 3 is arranged at the rear end of the first telescopic structure 1, the pusher plate 2 is located on the transmission table 3, the two sides on the transmission table 3 have baffles 31, and the baffles 31 have arc-shaped through grooves 32, and the transmission The rod 21 passes through the arc-shaped slot 32 .

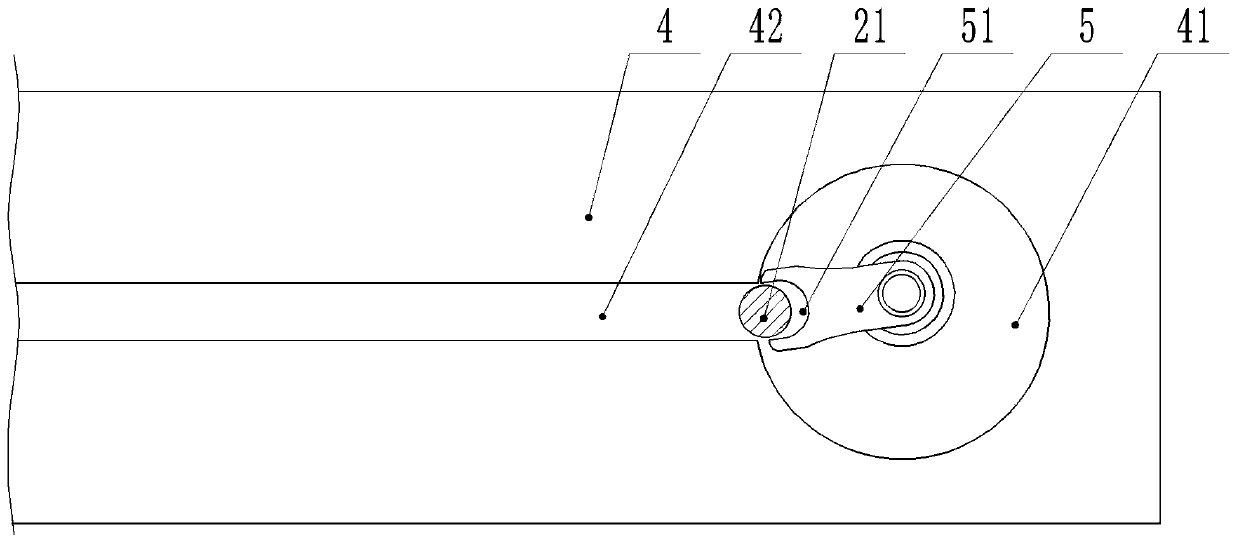

[0075] like image 3 , 4 As shown, the synchronous gripper 4 is arranged on both sides of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com