Multi-limb column used for fabricated steel structure house

A steel structure and assembly technology, applied in the field of multi-leg columns, can solve problems such as increased construction difficulty, increased construction period, and large component cross-sections, so as to ensure the support strength, improve construction efficiency, and solve the effects of wall leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

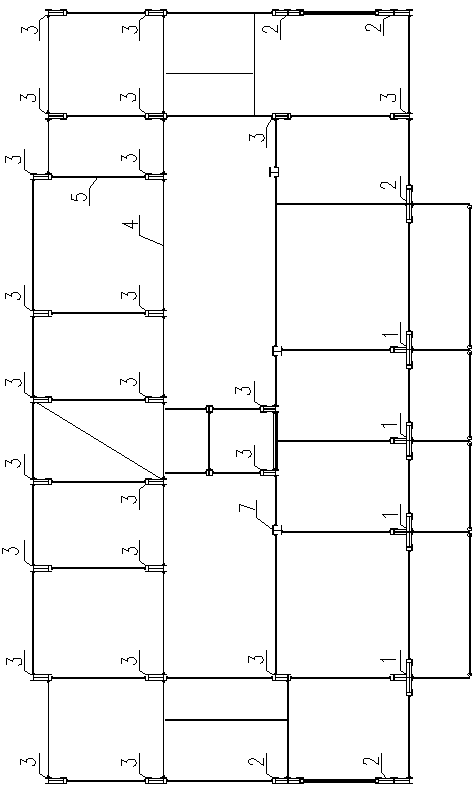

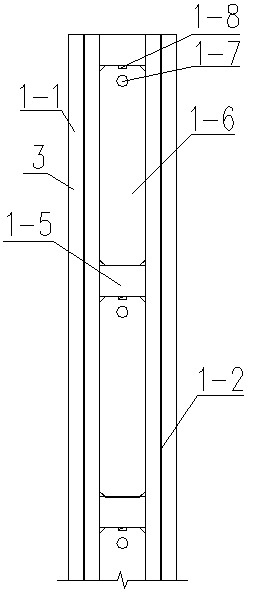

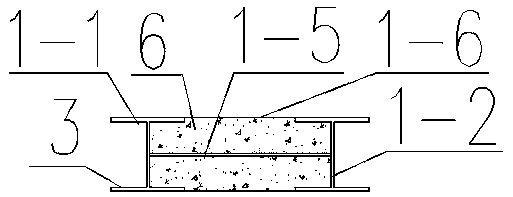

[0025] see figure 1 , this embodiment is a multi-leg column for a prefabricated steel structure residence, which is an earthquake-resistant project, which is a multi-storey residence with 7 floors above the ground, and the total height of the building is 23.100m (from the outdoor ground to the main roof). The seismic fortification intensity is 7 degrees, the design earthquake group is the second group, and the basic seismic acceleration is 0.15g. The project uses the PKPM2010 series software (V4.3 version) compiled by the China Academy of Building Research for structural calculations, and all results meet the design requirements. The frame of the prefabricated steel structure house is composed of wall columns, beams 4 and longitudinal beams 5 of each floor welded. Wall columns adopt multi-leg columns and steel columns 7, and there are three ty...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap