Device and method for adjusting and controlling wear dust distribution of pantograph-catenary contact pair

A technology of regulating device and contact pair, which is used in measuring devices, using mechanical devices, testing electrical devices in transportation, etc., can solve problems such as mechanical wear of friction pairs, achieve balance, improve severe friction and wear, and reduce roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

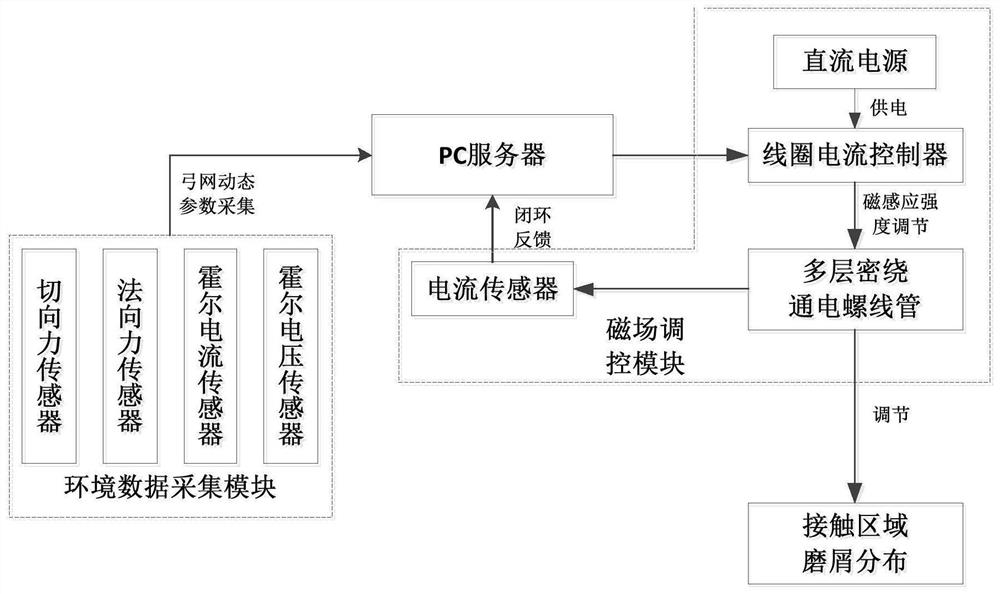

[0060] Such as figure 1 As shown, a pantograph-catenary contact wear debris distribution control device includes a magnetic field control module, an environmental data acquisition module and a PC server;

[0061] Both the magnetic field control module and the environmental data acquisition module are connected to the PC server;

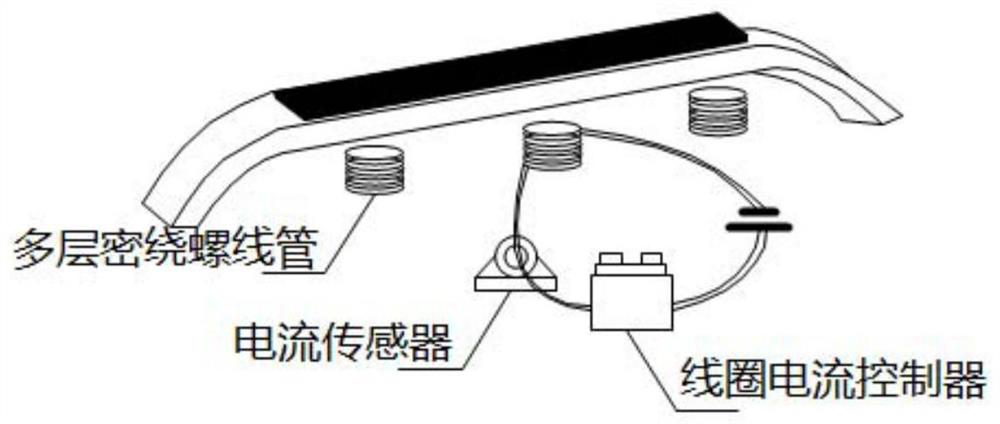

[0062] The magnetic field control module includes a current sensor, a coil current controller, a DC power supply and a multi-layer close-wound solenoid, and the current sensor and the coil current controller are both connected to the PC server, and the DC power supply is connected to the Coil current controller connection;

[0063] The environmental data acquisition module includes a force sensor, a Hall current sensor and a Hall voltage sensor all connected to the PC server.

[0064] The magnetic field control module in the embodiment of the present invention is used to generate the corresponding magnetic induction intensity in the contact area of ...

Embodiment 2

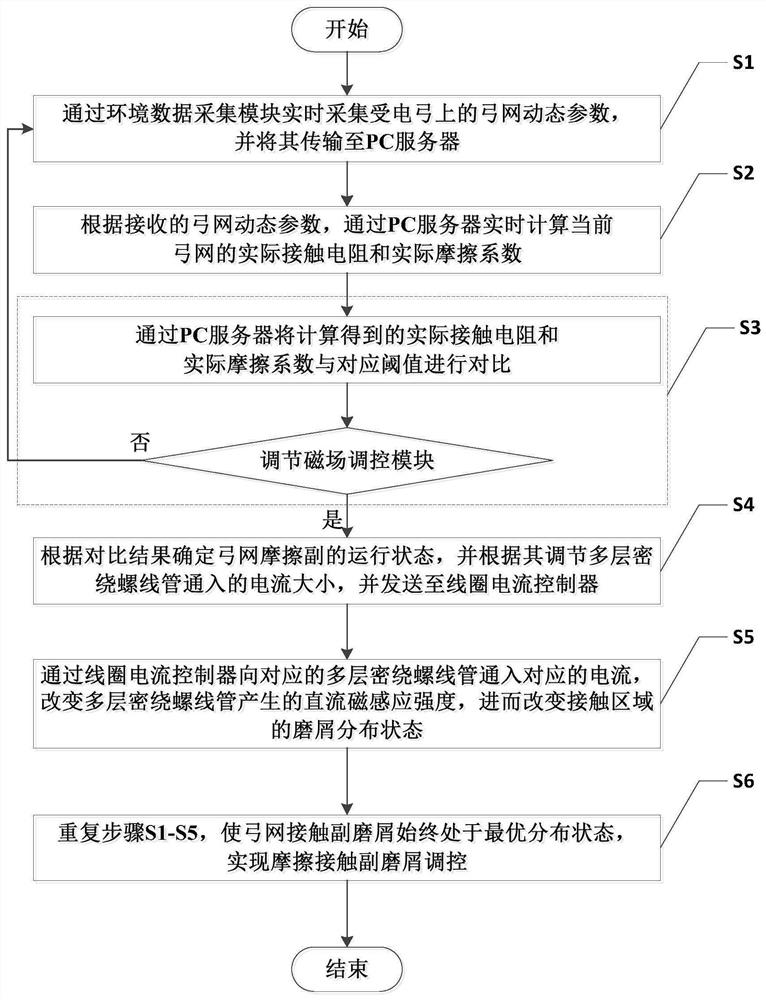

[0076] Such as image 3 Shown: a pantograph-catenary contact wear debris distribution control method, including the following steps:

[0077] S1. Collect the pantograph-catenary dynamic parameters on the pantograph in real time through the environmental data acquisition module, and transmit them to the PC server;

[0078] S2. According to the received pantograph-catenary dynamic parameters, calculate the actual contact resistance and actual friction coefficient of the current pantograph-catenary in real time through the PC server;

[0079] S3. Comparing the calculated actual contact resistance and actual friction coefficient with the corresponding threshold through the PC server, and then judging whether to adjust the magnetic field control module;

[0080] If yes, enter step S4;

[0081] If not, return to step S1;

[0082] S4. Determine the operating state of the pantograph-catenary friction pair according to the comparison result, and adjust the current size of the multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com