System and method for acquiring working voltage of crystal oscillator, and chip

A technology of crystal oscillator and working voltage, applied in CAD circuit design and other directions, can solve the problem of high power consumption of crystal oscillator, achieve the effect of stabilizing oscillation frequency, reducing chip power consumption and reducing overall power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

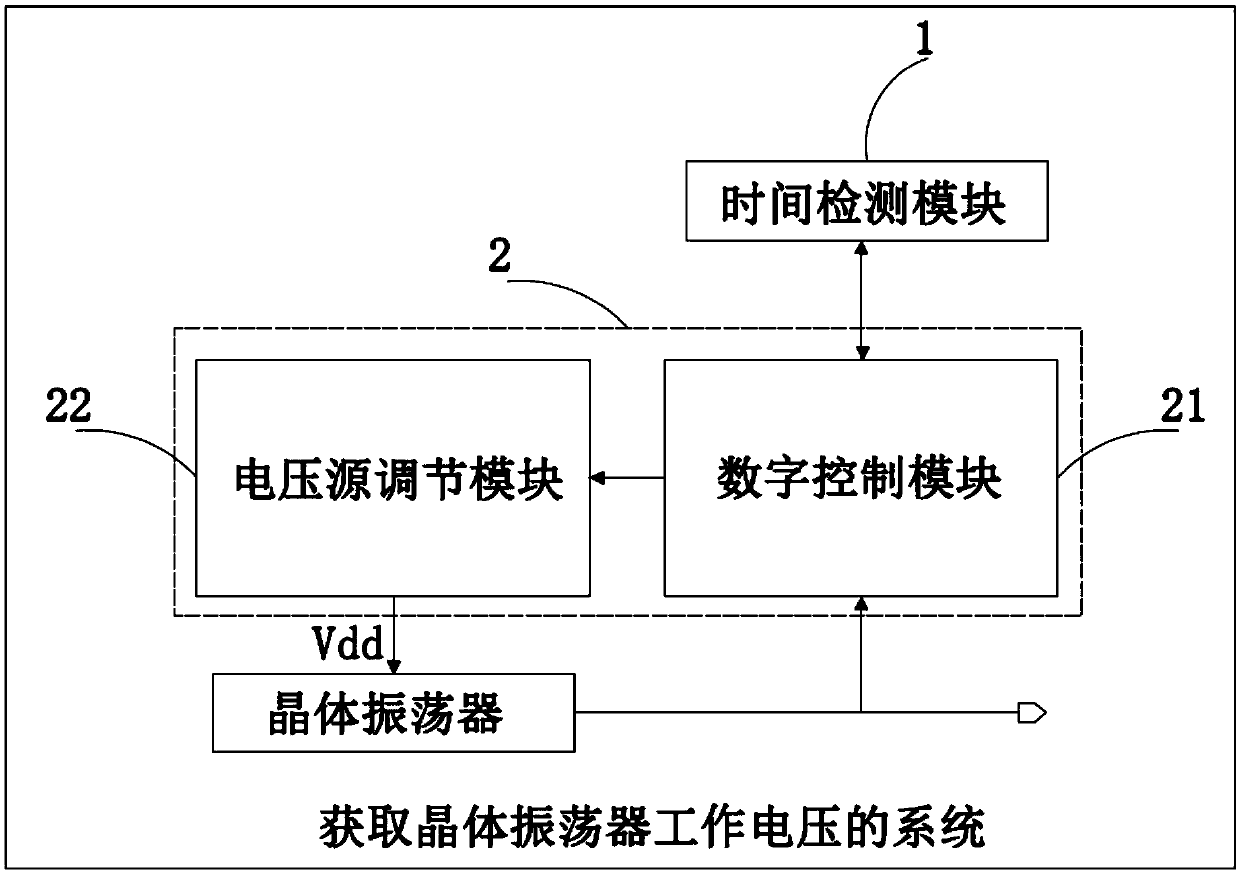

[0026] Such as figure 1 As shown, a system for obtaining the working voltage of a crystal oscillator includes a time detection module 1, a control circuit 2,

[0027] The time detection module 1 detects the dead time of the crystal oscillator, the time detection module adopts a controllable clock, and the controllable clock can accurately detect the dead time of the crystal oscillator;

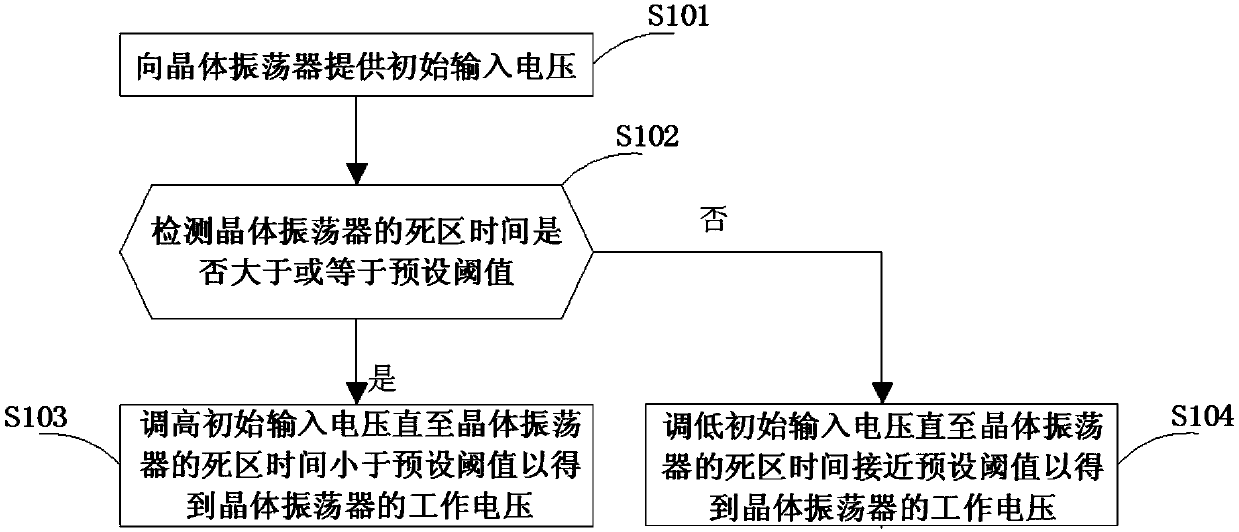

[0028] The control circuit 2 is connected to the time detection module 1 and the crystal oscillator, and provides an input voltage to the crystal oscillator according to the dead time detected by the time detection module 1, wherein when the crystal When the dead time of the oscillator is greater than or equal to the preset threshold, repeating the steps of increasing the input voltage of the crystal oscillator and detecting the dead time of the crystal oscillator until the dead time of the crystal oscillator is less than the preset threshold The preset threshold to obtain the operating volta...

specific Embodiment 2

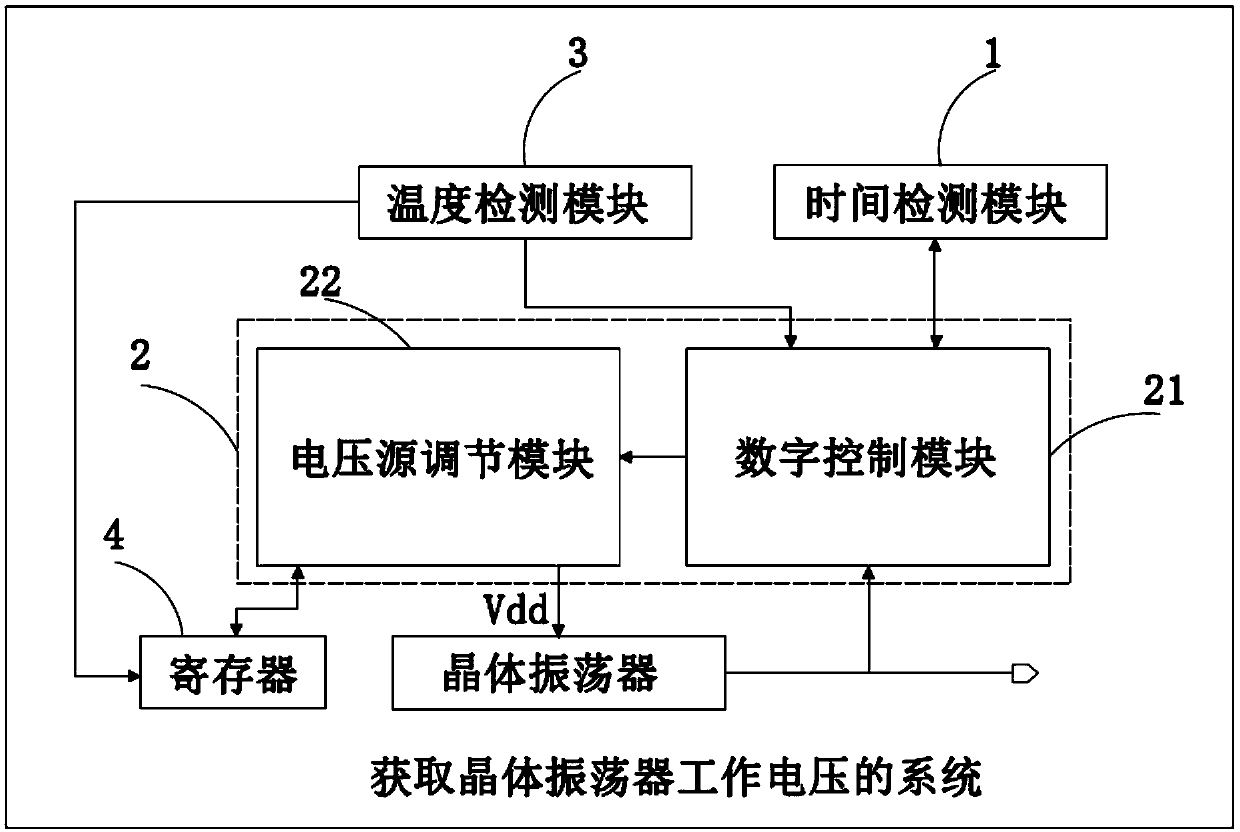

[0041] Such as image 3 As shown, the system for obtaining the operating voltage of the crystal oscillator in this embodiment has the same time detection module 1 and control circuit 2 as in the first embodiment. The difference from the first embodiment is that due to the working environment of the crystal oscillator The temperature change is uncontrollable, and in this embodiment also includes a temperature detection module 3, a register 4,

[0042] The temperature detection module 3 detects the change of the ambient temperature of the crystal oscillator, wherein when the change of the ambient temperature of the crystal oscillator exceeds the warning range, the control circuit 2 repeats the adjustment according to the dead time of the crystal oscillator. The input voltage of the crystal oscillator to obtain the operating voltage of the crystal oscillator, the register 4 stores and memorizes the operating voltage of the crystal oscillator readjusted by the control circuit 2 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com