High-capacity lithium battery with high-energy-density multi-pole column structure

A technology with high energy density and column structure, which is applied to structural parts, secondary batteries, battery pack parts, etc., can solve the problems of long total length of lithium batteries and occupying more space, so as to save production time and improve production efficiency , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

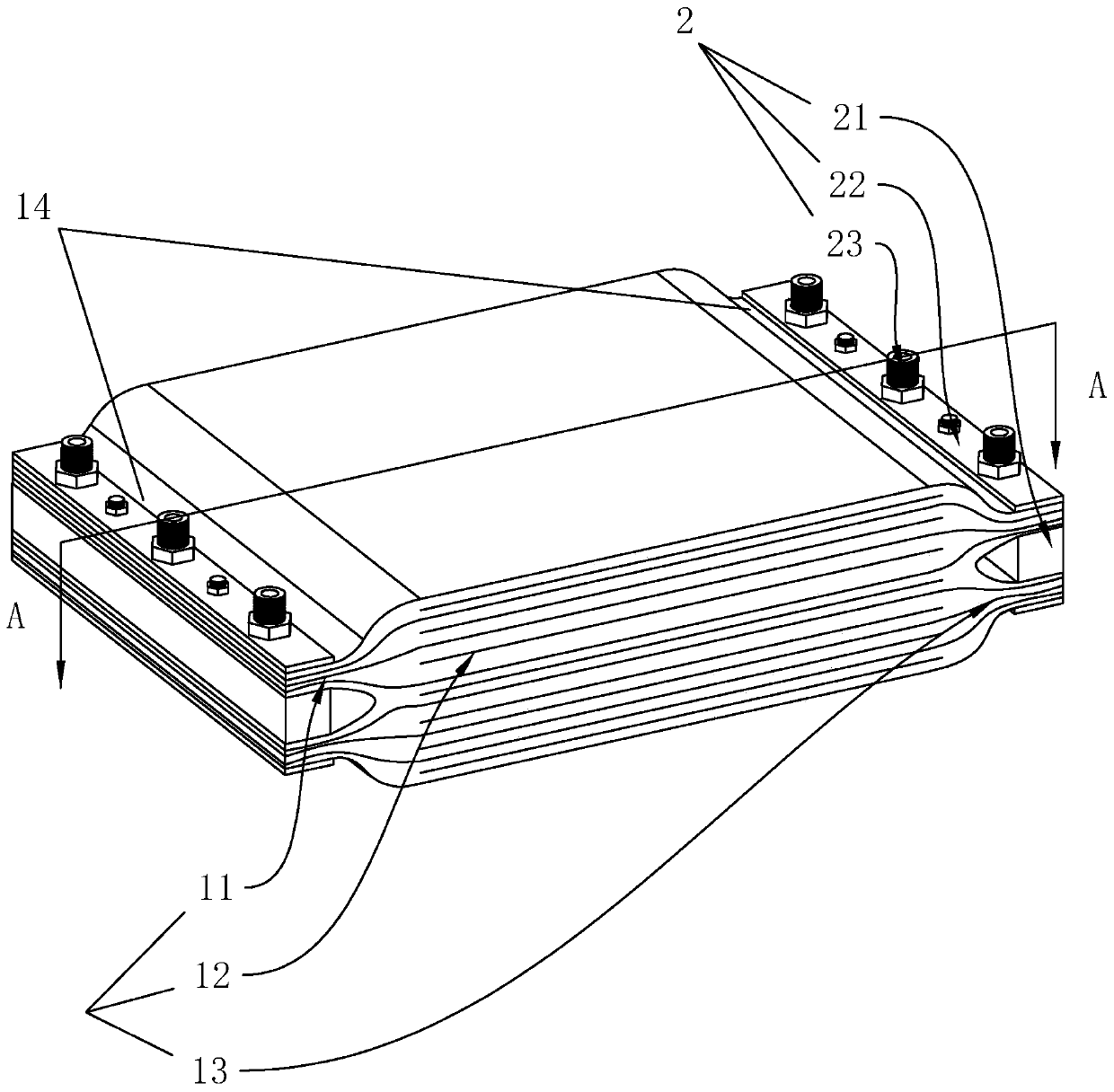

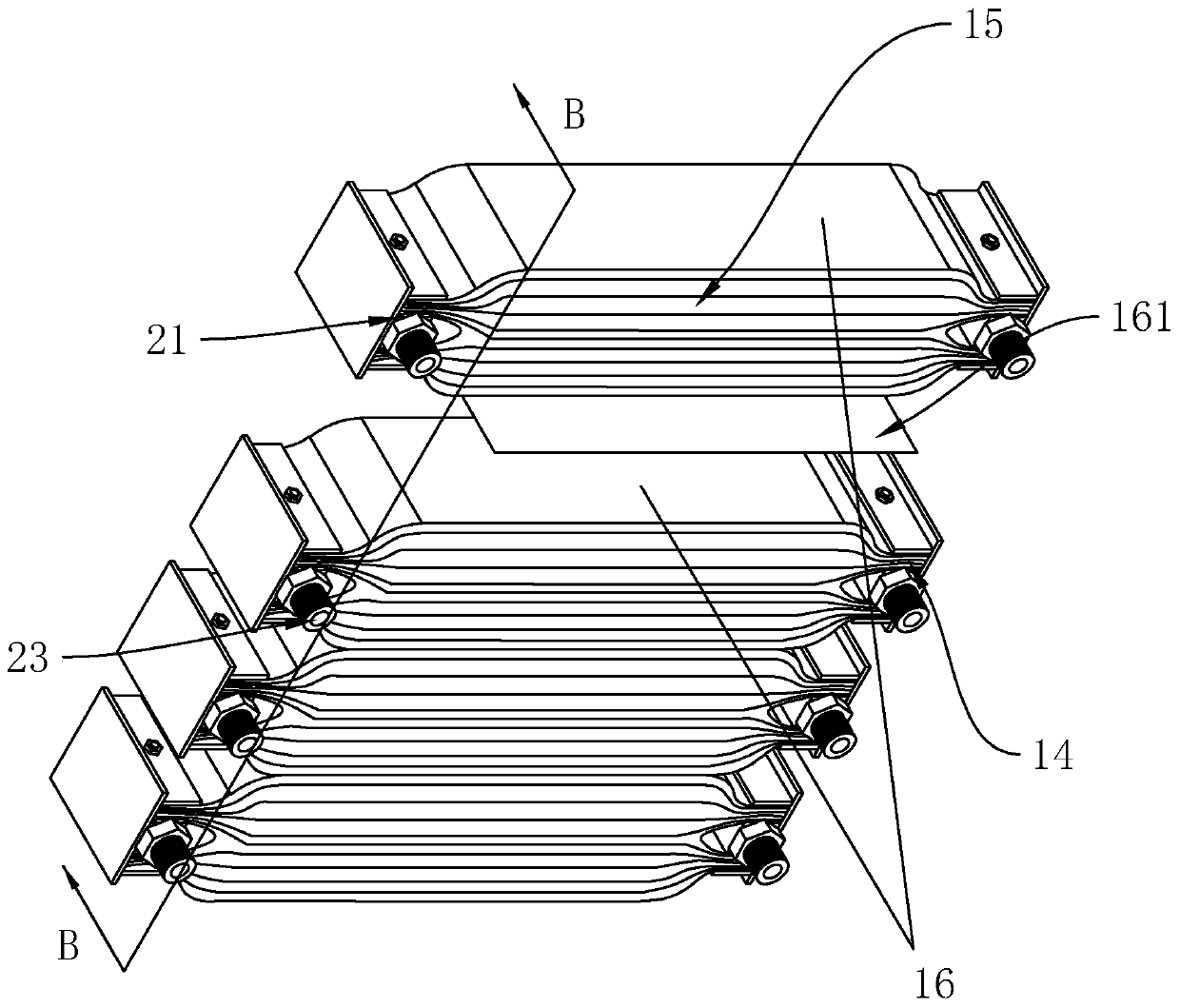

[0057] combine image 3 with Figure 4 As shown, the difference from Embodiment 1 is that the battery core 1 is formed by a combination of several sub-cores 15, and the bundle head 2 with a pole is provided with several pieces and evenly distributed at both ends of each sub-core 15, and the The bundle head 2 with a pole at one end of the sub-core body 15 is connected to the uncoated base half surface end 14 of each positive electrode piece 11 of the sub-core body 15, and the bundle head 2 with a pole set at the other end of the sub-core body 15 It is connected to the uncoated base half surface end 14 of each negative electrode sheet 12 of the sub-core body 15; wherein, on one of the side surfaces of each sub-core body 15, two battery core bodies for any adjacent arrangement are pasted 1 separated second diaphragm 16 , and a release film 161 is pasted on the side of each second diaphragm 16 away from the sub-core body 15 .

[0058] When it is necessary to connect any adjacent...

Embodiment 3

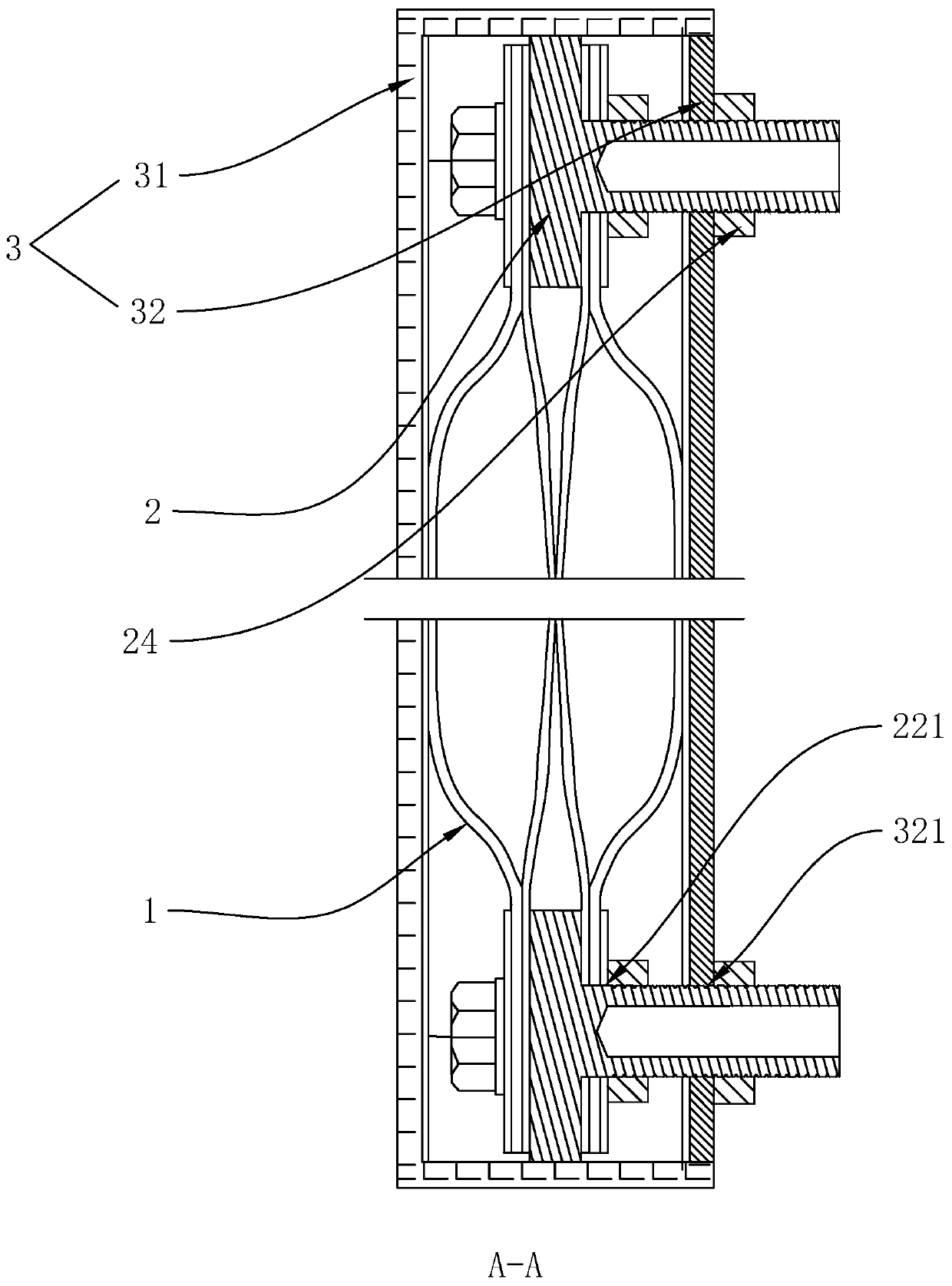

[0062] combine Figure 5 with Image 6 As shown, the difference from Embodiment 1 is that the battery core 1 is formed by combining several sub-cores 15 , and the casing 3 includes a battery case 31 with a side opening and a cover plate 32 for covering the opening of the battery case 31 A plurality of through holes 321 arranged along the width direction of the cover plate 32 are provided on both ends of the cover plate 32 and on both ends of the side of the battery case 31 away from the opening, and the holes 321 arranged on the cover plate 32 The positions of the through holes 321 and the through holes 321 disposed on the battery case 31 are alternately arranged.

[0063] When it is necessary to assemble each sub-core body 15 with the housing 3, at first one of the sub-core bodies 15 is installed on one side of the battery case 31, and the width direction of the sub-core body 15 is along the along the thickness direction of the battery case 31, and make the length direction...

Embodiment 4

[0066] combine Figure 7 with Figure 8 As shown, the difference from Embodiment 1 is that the casing 3 includes a battery case 31 with a side opening and a cover plate 32 for covering the opening of the battery case 31. On both ends of the cover plate 32 and the battery case 31 is away from Both ends of one side of the opening are provided with a plurality of through holes 321 arranged along the width direction of the cover plate 32 , and the through holes 321 arranged on the cover plate 32 are connected with the through holes 321 arranged on the battery case 31 . The through holes 321 are arranged as mirror images of each other; wherein, there are two poles 23 on the beam head body 21 , and the two poles 23 are symmetrically arranged on the left and right sides of the beam head body 21 .

[0067] When it is necessary to assemble each sub-core body 15 with the housing 3, it is only necessary to put each sub-core body 15 into the housing 3 from the opening of the battery case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com