Erhu tube glue brushing and splicing device for Erhu production

A splicing device and glue brushing technology, which is applied in the direction of adhesive application device, device for coating liquid on the surface, bonding of wooden veneer, etc. Work efficiency, low work intensity, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

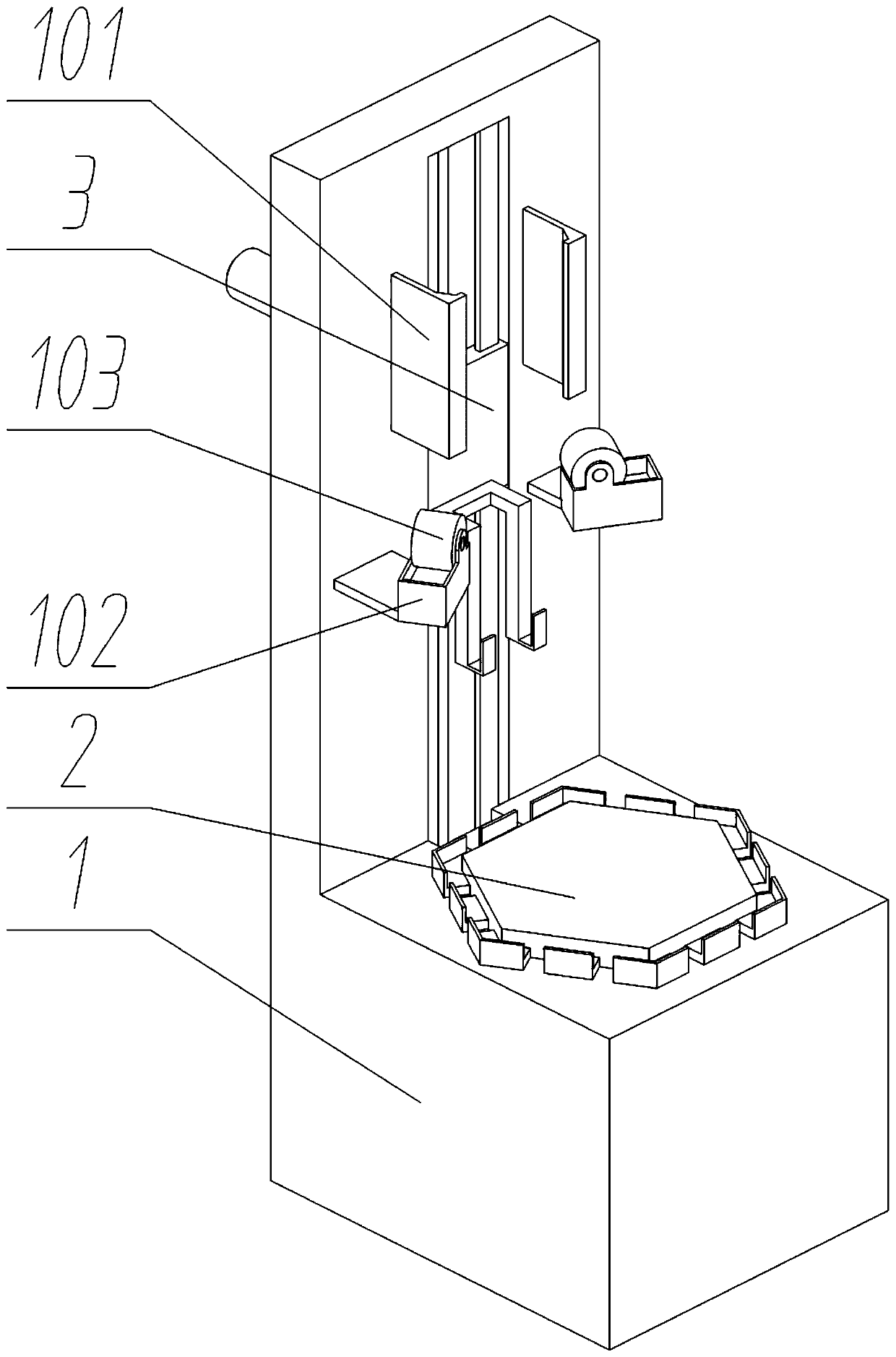

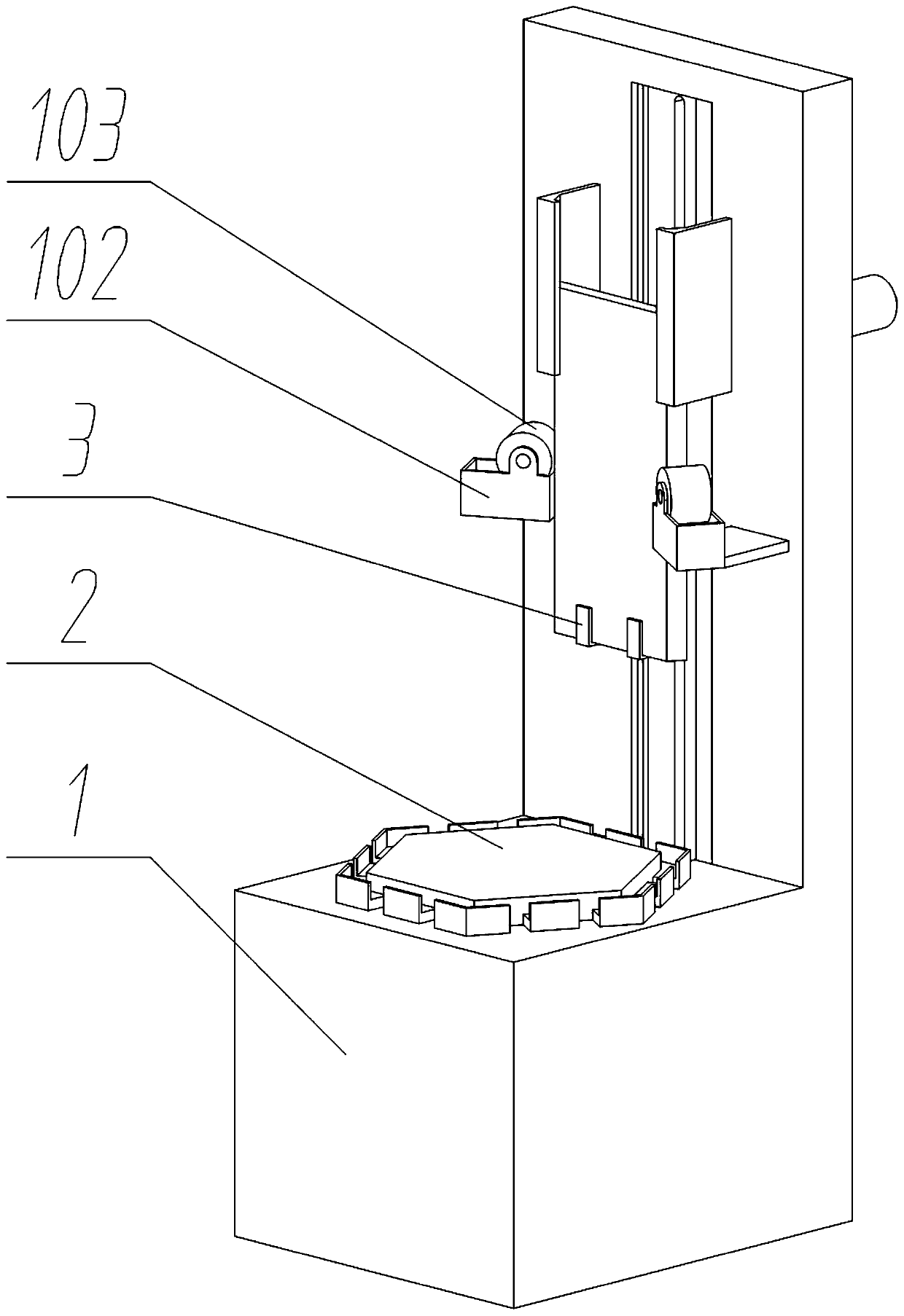

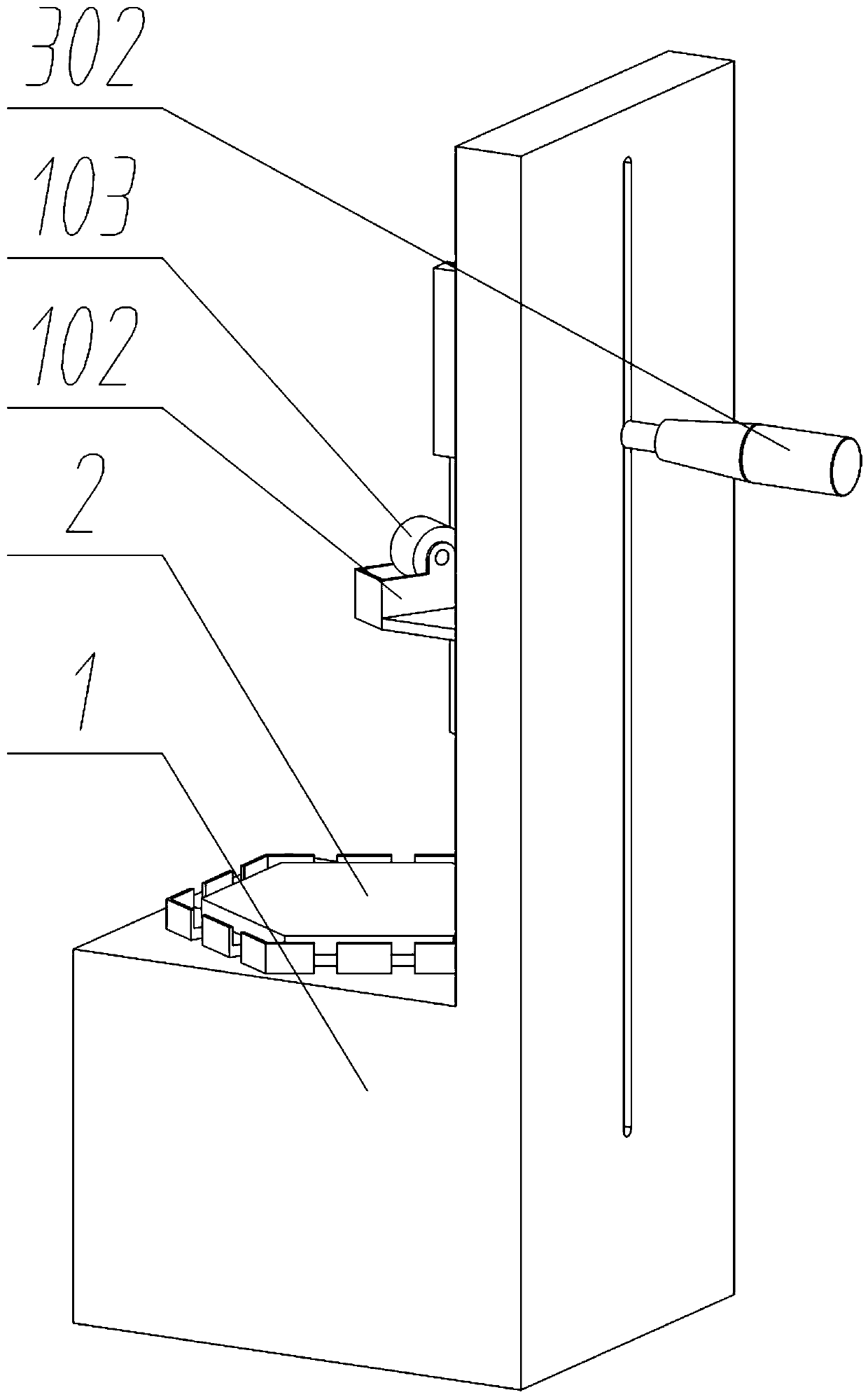

[0029] see Figure 1 to Figure 5 , Figure 7 and Figure 8 , an embodiment provided by the present invention: a qin tube glue splicing device for erhu production, including a main body 1; the main body 1 also includes a plank positioning block 101, and a Set the plank positioning block 101, guide the block by the plank positioning block 101 in use to ensure the placement position of the block; the main body 1 also includes a rubber box 102, a rubber brush roller 103, and the upper front end of the main body 1 is provided with a left and right The glue box 102, the top of the glue box 102 is axially connected with a set of brush rollers 103, and the brush roller 103 is used to brush the glue that drives the glue box 102 onto the wooden board; the middle part of the main body 1 is axially connected with a set of rotating The splicing table 2; the rotary splicing table 2 also includes gaps 201, and the outer circumference of the rotary splicing table 2 is arranged in an array w...

Embodiment 2

[0031] On the basis of Example 1, please refer to Figure 6 , a kind of embodiment that the present invention provides: a kind of glue brush splicing device for erhu production, driven pulley 4 also includes driving bevel gear 401, the left side of driven pulley 4 is coaxially fixedly connected with a A set of driving bevel gears 401, the rotary splicing table 2 also includes a driven bevel gear 202, the bottom of the rotary splicing table 2 is coaxially fixedly connected with a set of driven bevel gears 202, the driving bevel gear 401 and the driven bevel gear 202 mesh together to form The bevel gear transmission mechanism, in use, the driven pulley 4 drives the rotary splicing table 2 to rotate through the bevel gear transmission mechanism.

[0032] Further, a group of synchronous transmission belts are wound around the outside of the driven pulley 4 and the driving pulley 5 together to form a synchronous belt transmission mechanism. In use, the driving pulley 5 drives the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com