Hybrid reflective three-dimensional linkage laser cutting head

A technology of laser cutting head and mixed reflection, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of difficult debugging, unstable optical path, high maintenance cost, etc., and achieve easy debugging and maintenance, and facilitate the layout of optical path , The effect of convenient fiber plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

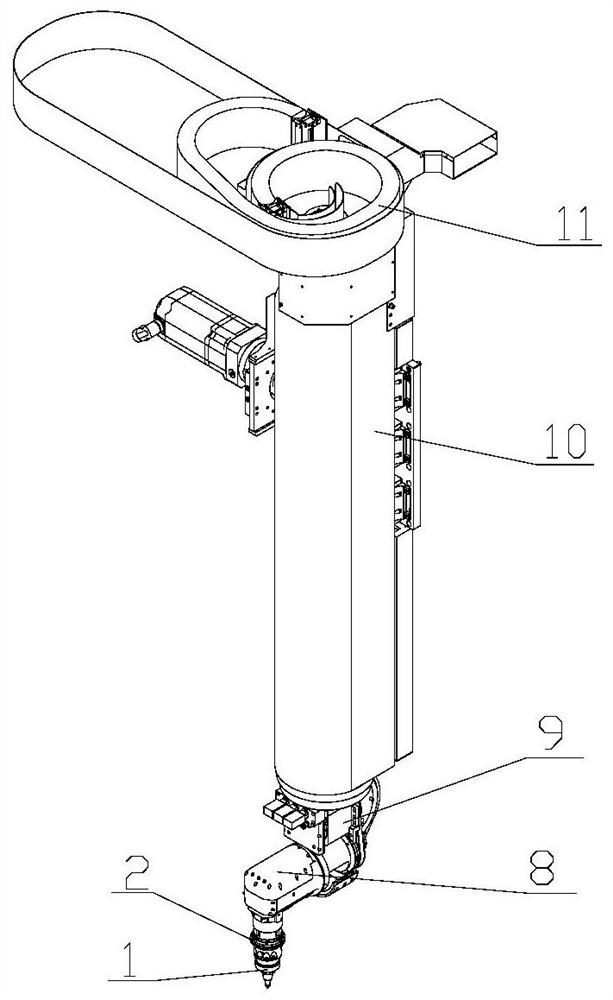

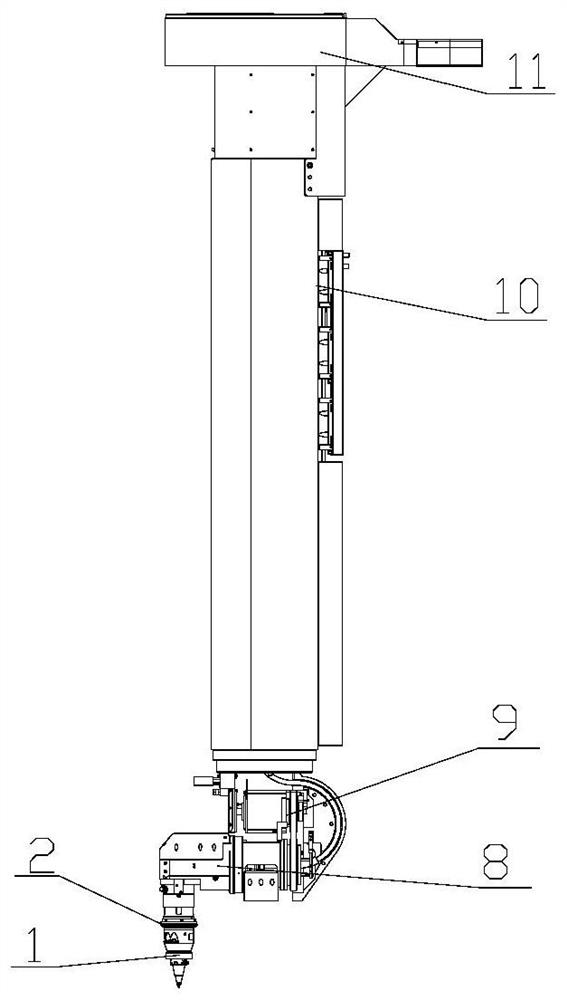

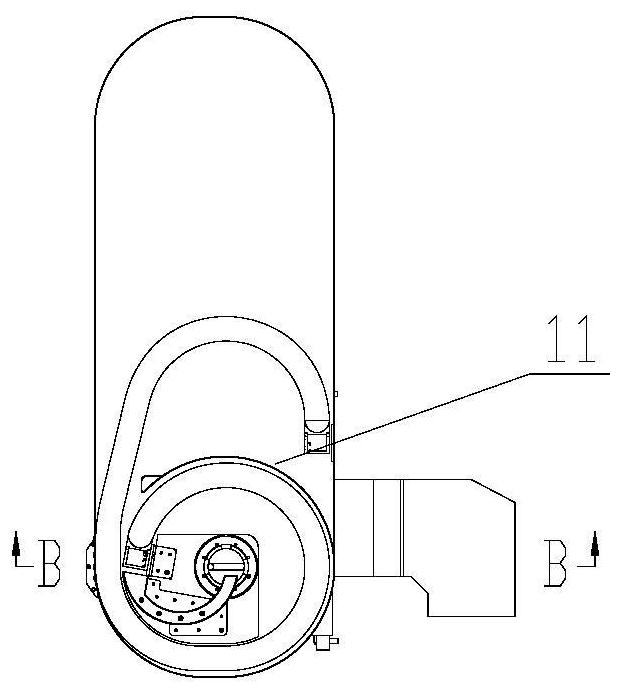

[0037] like Figure 1-4 As shown, a hybrid reflective three-dimensional linkage laser cutting head provided by the present invention includes a focusing module 1, an anti-collision module 2, a follower module 3, an optical element module, an optical fiber 90° module 7, a swing axis module 8, and a rotation axis Module 9, vertical main shaft module 10 and rotating drag chain module 11, wherein the upper and lower ends of the anti-collision module 2 are respectively connected with the swing axis module 8 and the focus module 1, and the swing axis module 8 can drive the focus module 1 to swing around the horizontal axis up and down , the follow-up module 3 and the optical element module are arranged in the swing axis module 8, the follow-up module 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com