PU/PVC double-traction scraping and coating conveyor belt production line

A conveyor belt and production line technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve problems such as surface tension fluctuations of conveyor belts, achieve the effects of avoiding deviations and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

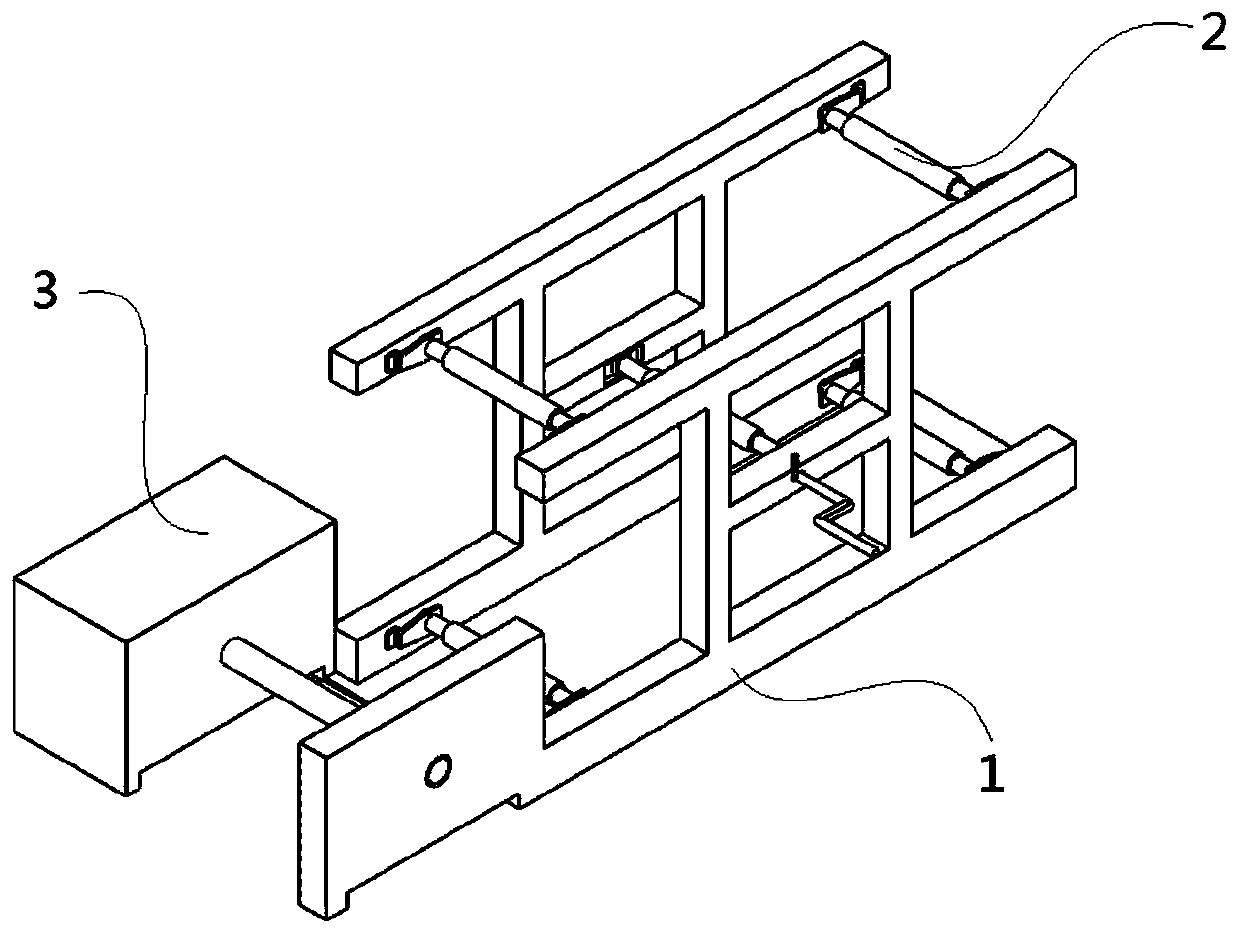

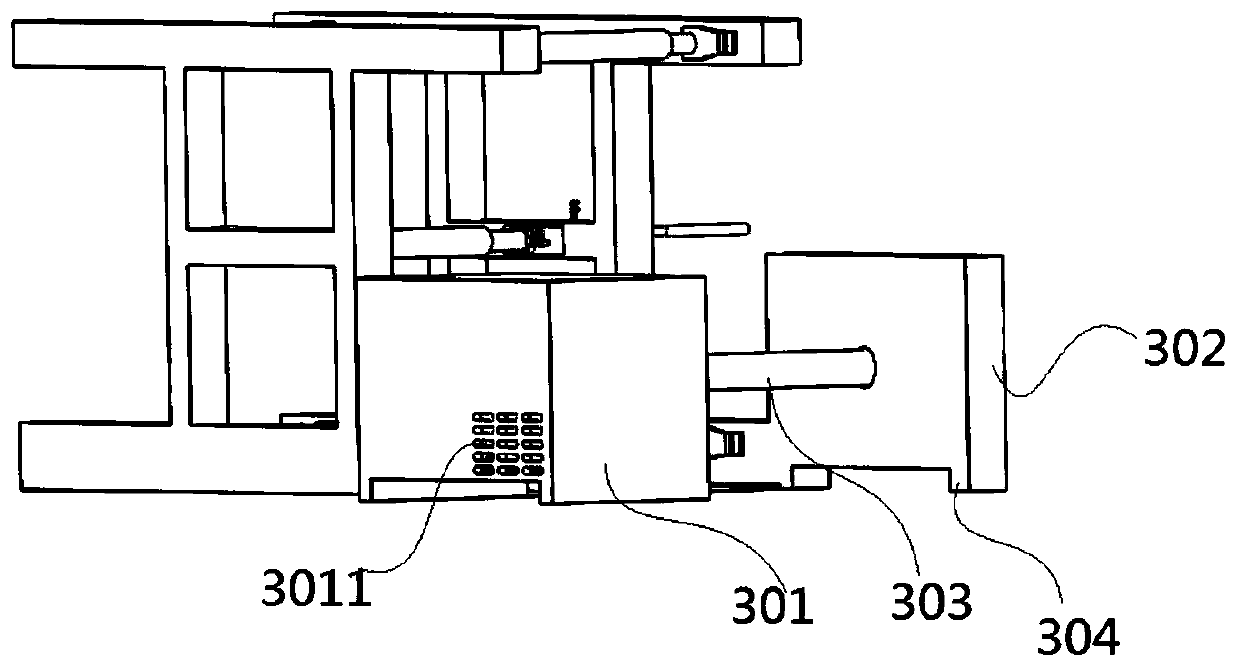

[0047] see Figure 2-7 As shown, this embodiment is a working principle of an adjustable five-roller winding tractor:

[0048] In this embodiment, the model of the traction motor is CYT-503, and the rated voltage is 220V.

[0049] As mentioned above, install the tractor in the production line, start the traction motor 3 to start working, when the surface tension of the conveyor belt deviates, rotate the rocker 101, adjust the roller 2, change the position of the roller 2, and adjust the surface tension of the conveyor belt , to make it adapt to the production process; in addition, the barrier plate 104 on the surface of the support frame 1 limits the position of the conveyor belt; by adjusting the telescopic joint 1042, the limit plate 1043 is adjusted to adapt to the position of the conveyor belt.

Embodiment 2

[0051] see Figure 2-7 As shown, this embodiment is a PU / PVC double-traction scraping conveyor belt production line, the specific application and function of the adjustable five-roller winding tractor in the production line:

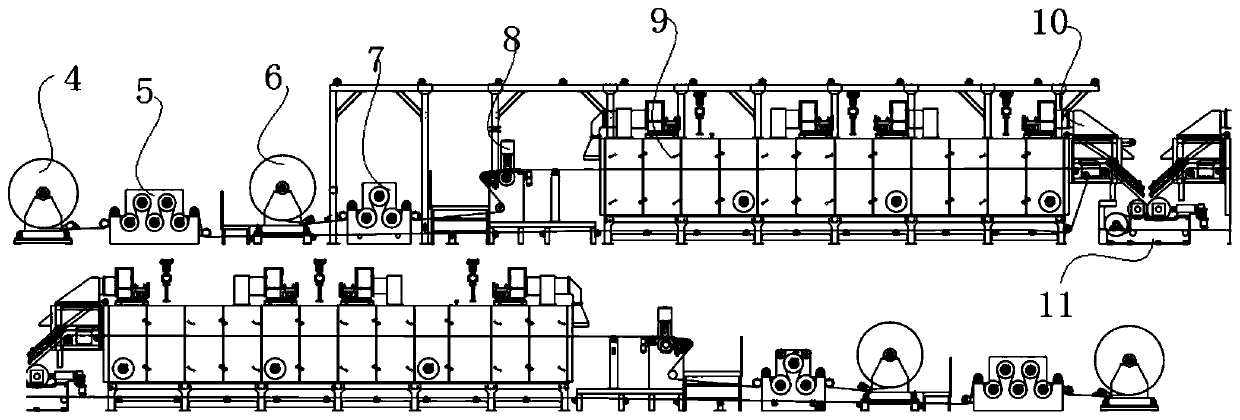

[0052] In the PU / PVC double-traction scraping conveyor belt production line, the equipment arrangement is as follows: The present invention is a PU / PVC double-traction scraping conveyor belt production line, and the equipment arrangement is as follows: active winder 4, 5 Roller winding tractor 5, active unwinding machine 6, three-roller unwinding tractor 7, coating machine 8, oven 9, auxiliary heating equipment 10, calender laminating machine 11, auxiliary heating equipment 10, oven heating 9, Coating machine 8, three-roller unwinding tractor 7, active unwinding machine 6, five-roller winding tractor 5 and active winding machine 4;

[0053] In this production line, by changing the three-roller winding tractor to the five-roller winding tractor 5, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com