High-carbon wire rod with excellent drawing performance and manufacturing method thereof

A kind of wire rod, excellent technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of cementite fragmentation, micropore change, etc., and achieve the effect of excellent drawing processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

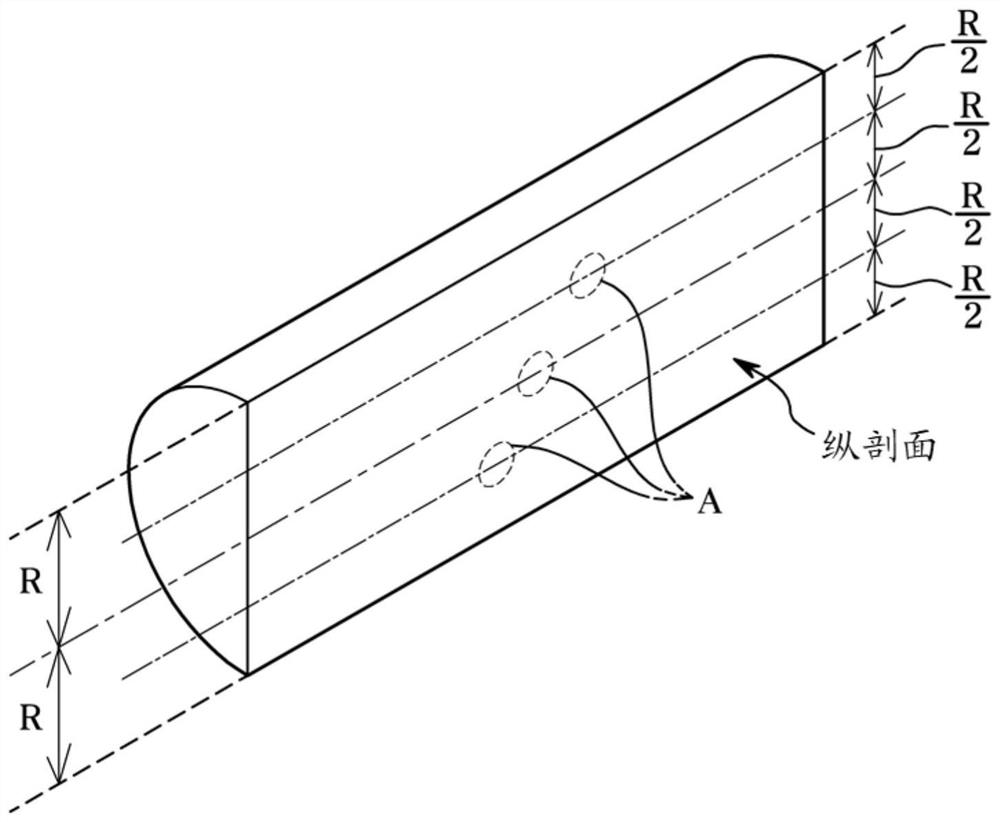

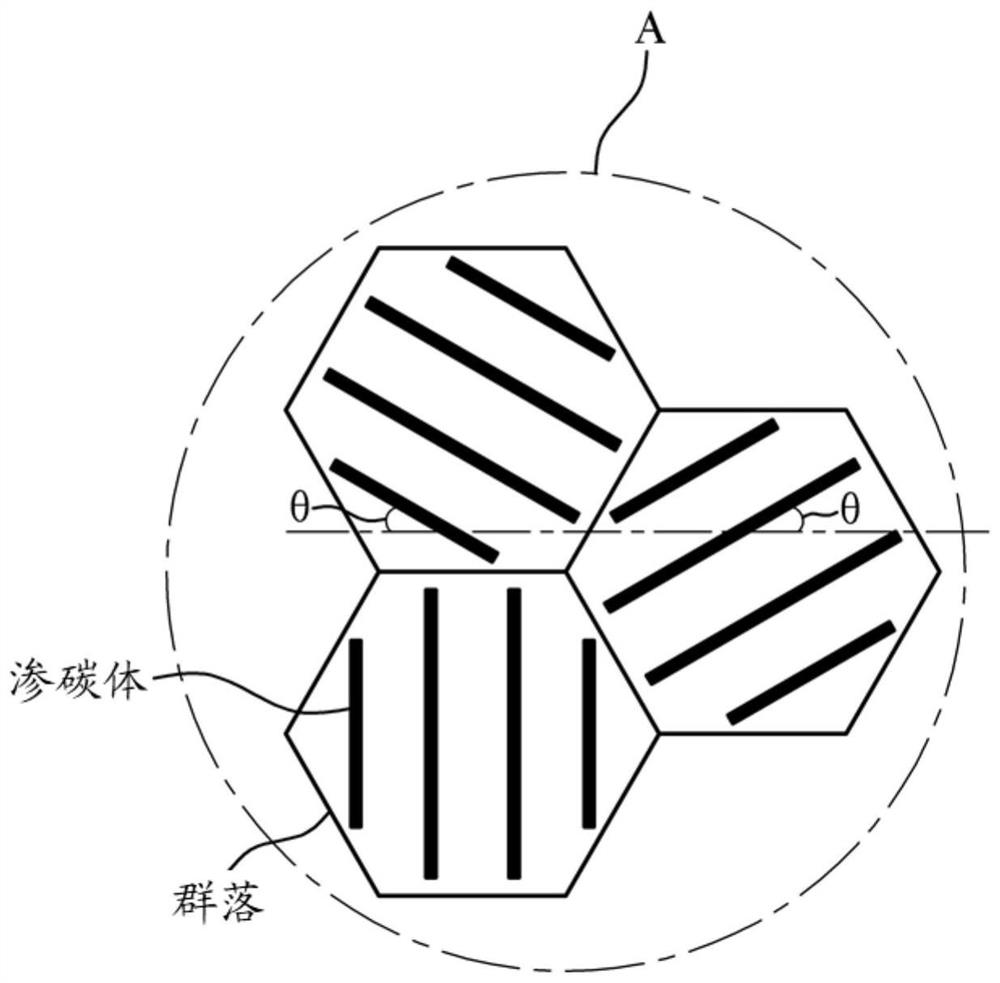

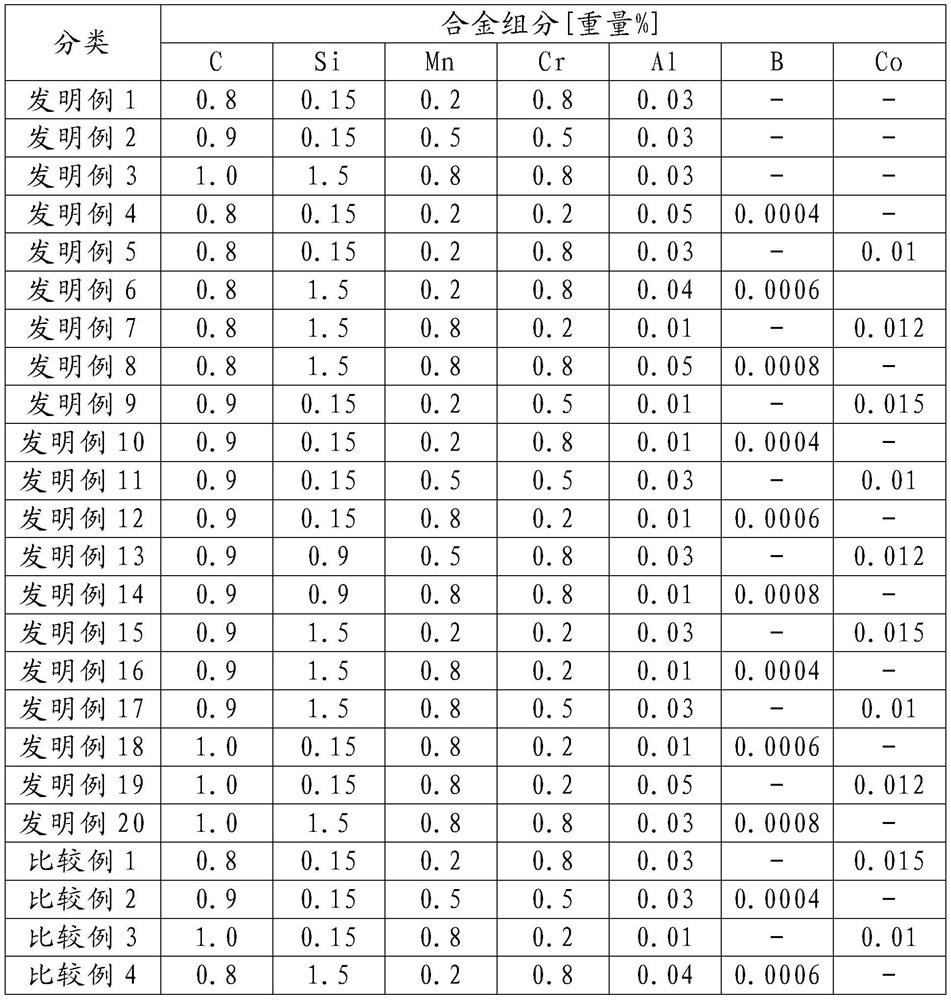

[0068] After casting an ingot (70Kg) having the alloy composition (% by weight) shown in Table 1 below, it was heated in a heating furnace at 1100°C for about 2 hours, and then taken out from the heating furnace and heated at a temperature of 900°C or higher. Down rolled into a wire with a wire diameter of 13mm. Then, the rolled wire rod was water-cooled, coiled at 850°C, and then immersed in a previously prepared nitrate bath at 400°C to 550°C for 5 minutes, and then the longitudinal section of the material was taken out for observation.

[0069] 【Table 1】

[0070]

[0071] 【Table 2】

[0072]

[0073] Invention Examples 1 to 3 contain C: 0.8% to 1.0%, Si: 0.15% to 1.5%, Mn: 0.2% to 0.8%, Cr: 0.2% to 0.8%, Al: 0.05% or less, and the remainder in % by weight Fe and unavoidable impurities are contained in an amount or the balance, and are manufactured by a manufacturing method including a step of cooling the coiled wire by immersing it in 450°C nitrate containing 0.02% t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com