High-carbon wire with uniform internal material and manufacturing method thereof

A manufacturing method and wire rod technology, applied in the manufacture of tools, furnaces, heat treatment equipment, etc., can solve the problems of high work hardening rate, uneven material, high initial strength, etc., and achieve the effect of excellent drawing processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

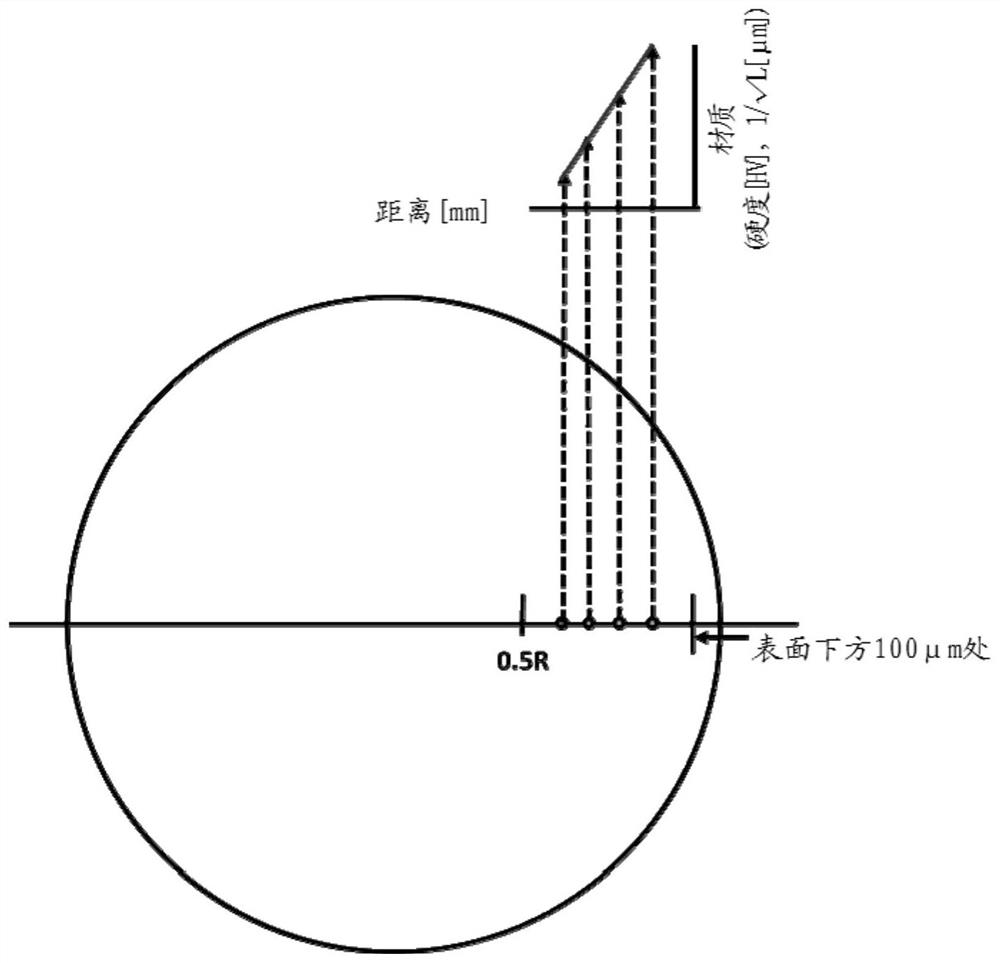

Image

Examples

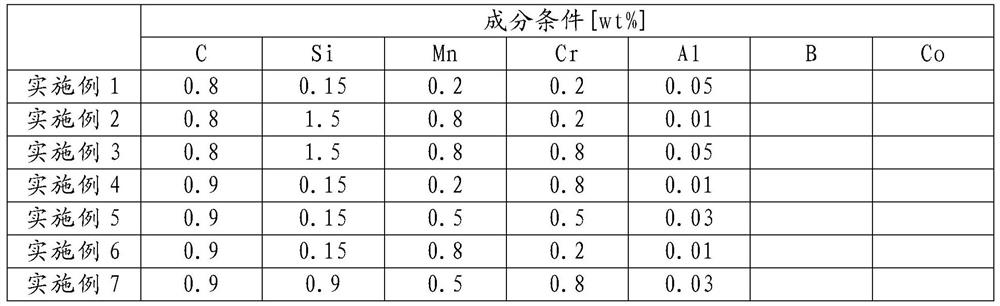

Embodiment 1 to 11

[0096] After casting an ingot (70Kg) that satisfies the alloy composition shown in Table 1, heat it in a heating furnace at 1100°C for about 2 hours, then take it out from the heating furnace, and roll it at a temperature above 900°C to form a wire diameter of 13mm. wire. Then, the rolled wire rod is cooled by water cooling, and then coiled at 750°C to 950°C.

[0097] Then, place the coiled wire on the stelmor (stelmor) line, adjust the holding time by adjusting the air supply volume or immersing in a salt bath to adjust the temperature of the 50°C region before the phase change of the wire is heated, that is, 490 The cooling rate between ℃ and 630 ℃ is controlled to be 5 ℃ / s-30 ℃ / s, and the cooling time of the phase change heating zone is controlled to be 2 seconds to 20 seconds, and the cooling is carried out in this way.

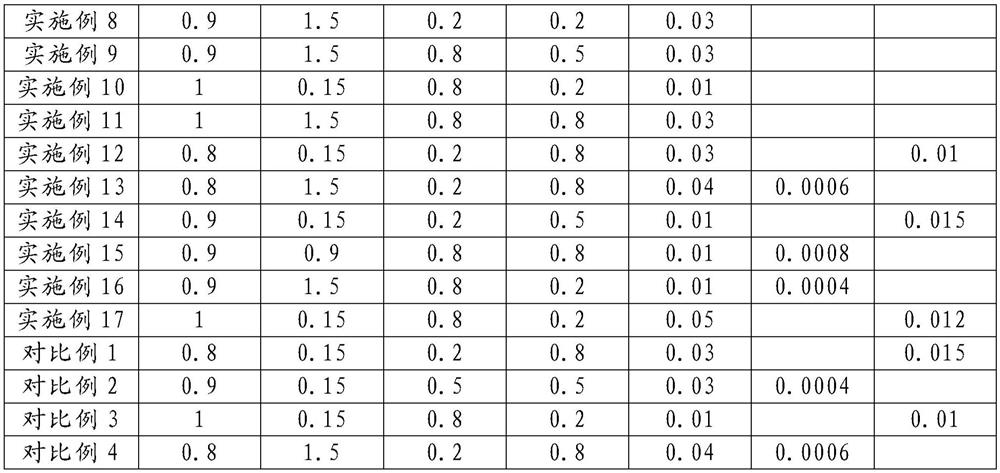

Embodiment 12 to 17

[0099] In embodiments 1 to 11, at least one of boron (B): 0.0003% to 0.0008% or cobalt (C0): 0.01 to 0.015% is selectively added, except that the others are the same as in embodiments 1 to 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com