Diamond-like protective coating and preparation method thereof

A technology of protective coating and diamond layer, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of slow deposition rate, small depth of DLC coating, poor quality, etc., and achieve simple process , good coating quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of a diamond-like protective coating, comprising the following steps:

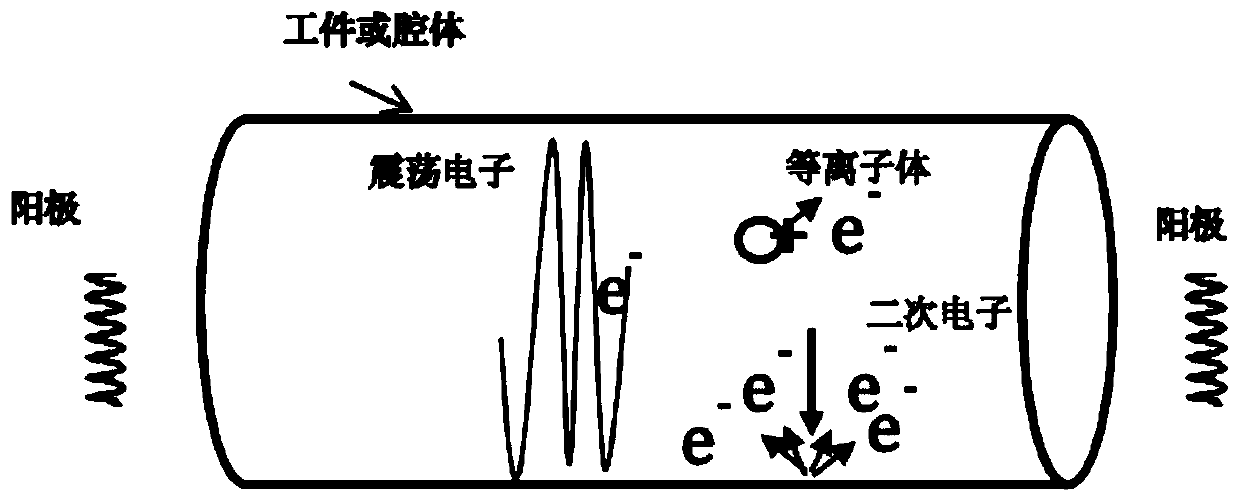

[0024] A hollow cathode discharge plasma chemical vapor deposition technique is used to sequentially deposit a silicon-doped diamond-like bottom layer and a diamond-like layer on the surface of a substrate.

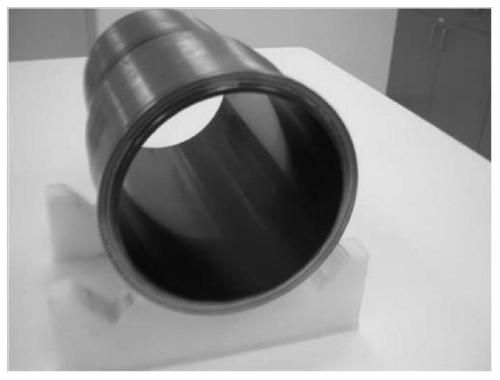

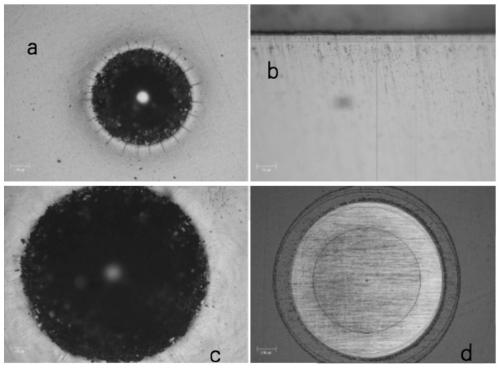

[0025] The invention adopts the hollow cathode discharge plasma chemical vapor deposition technology to deposit the silicon-doped diamond-like bottom layer on the substrate surface. In the present invention, the material of the substrate is preferably metal, specifically tool steel, stainless steel or hard alloy. In the present invention, the substrate is preferably a deep-hole part, a tool or a mold, and the preparation method provided by the present invention is especially suitable for deep-hole parts. In a specific embodiment of the present invention, the deep hole parts are preferably pipes with a hole diameter of 8-300mm and a diameter / length ra...

Embodiment 1

[0046] Polish the stainless steel deep-porous substrate with an aspect ratio of 10:1, and then clean the polished substrate with ultrasonic waves in absolute ethanol and acetone for 10 minutes, and the frequency of the ultrasonic wave is 30 kHz to obtain a substrate with a clean surface;

[0047] The surface-cleaned substrate is placed in PECVD equipment, the bias voltage of the hollow cathode bottom layer is -100V, the control voltage is 1200V; the pulse frequency is 20kHz; the C 2 h 2 The flow rate of silane is 200mL / min; the flow rate of silane is 15mL / min, and the processing time is 10min, and a silicon-doped diamond-like carbon bottom layer with a thickness of 0.5μm is obtained on the surface of the substrate;

[0048] Adjusting the parameters of the hollow cathode discharge plasma chemical vapor deposition technology, the reaction gas Ar / C 2 h 2 The flow ratio is 1:2, the temperature of the substrate is 100°C, the air pressure is 1.0Pa, the pulse bias voltage is 3000V,...

Embodiment 2

[0051] Polish the high-speed steel deep-hole substrate with an aspect ratio of 15:1, and then clean the polished substrate with ultrasonic waves in absolute ethanol and acetone for 10 minutes, and the frequency of the ultrasonic wave is 30 kHz to obtain a clean substrate;

[0052] The substrate with the clean surface is placed in PECVD equipment, the bias voltage of the hollow cathode bottom layer is -100V, the control voltage is 1000V; the pulse frequency is 20kHz; the C 2 h 2 The flow rate of silane is 200mL / min; the flow rate of silane is 15mL / min, and the processing time is 10min, and a silicon-doped diamond-like carbon bottom layer with a thickness of 0.5μm is obtained on the surface of the substrate;

[0053] Adjusting the parameters of the hollow cathode discharge plasma chemical vapor deposition technology, the reaction gas Ar / C 2 h 2 The flow ratio is 1:2, the temperature of the substrate is 200°C, the air pressure is 2.0Pa, the pulse bias voltage is 3000V, the puls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap