Manufacturing process of polyurethane filament knitted belt

A production process, a technology of spandex yarn, which is applied in the directions of textile, fabric, textile and paper making, etc., can solve the problems of uneven size of spandex webbing and deformation of spandex webbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

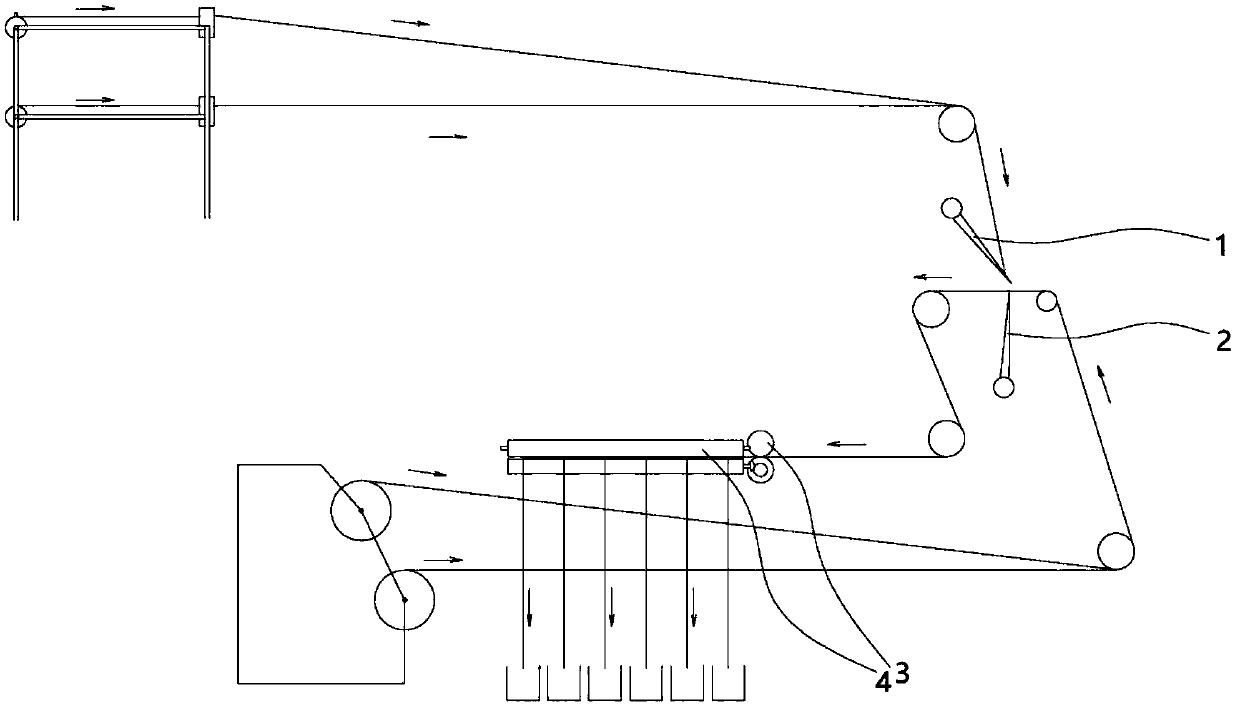

[0019] The following is attached figure 1 , 2 The specific embodiment of the present invention is described in further detail

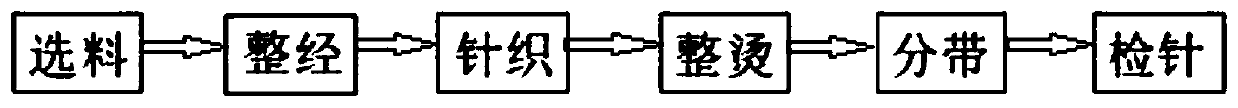

[0020] A manufacturing process of spandex silk webbing, comprising the following steps:

[0021] (1) Material selection, choose spandex yarn as the warp yarn of the ribbon, polyester yarn or nylon yarn as the weft yarn of the ribbon, the elastic elongation of the spandex yarn can reach 6-7 times, and the elastic recovery rate can reach 95%-98%. Accounting for 20%, polyester yarn or nylon yarn accounting for 80%, the F number of polyester yarn or nylon yarn is 150 ~ 180dtex / 48F; use electronic tension measurement to ensure consistent tension during warping process, and the package size of spandex yarn is consistent , The ribbon conveying speed is controlled at 35-40m / min.

[0022] (2) warping, the warp yarns on several first drums are wound onto one or more second drums by a yarn drawing machine, and the second drum segments are arranged to wind a wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com