Silver-doped copper vanadate composite photocatalytic material, preparation method thereof and application of silver-doped copper vanadate composite photocatalytic material as carbon dioxide reduction photocatalyst

A technology of composite photocatalysis and copper vanadate, which is applied in the direction of carbon monoxide, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Catalytic activity is not very high, photocatalysis is rarely reported, etc., to achieve high catalytic activity and stability, increase adsorption capacity, and broaden the photoresponse range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (comparative example)

[0046] CuV 2 o 6 Preparation of nanostructures: Weigh 0.402g of Cu(NO 3 ) 2 ·3H 2 Dissolve the O solid in 30ml of distilled water, stir and dissolve at room temperature until the yellow clear solution is recorded as A solution; weigh 0.303g of V 2 o 5 Disperse the solid in 30ml of pure water, stir at room temperature until the dispersion is uniform, and record it as B suspension; add B suspension to A solution drop by drop, continue stirring for 30 minutes, and record it as C suspension; adjust the pH at the same time =6, transfer the C suspension to a 100ml reactor, place the reactor in an oven, and react at a high temperature of 220°C for 24h. The yellow product obtained after the reaction was washed with water and ethanol, and then transferred to a vacuum drying oven at 50° C. for 6 h.

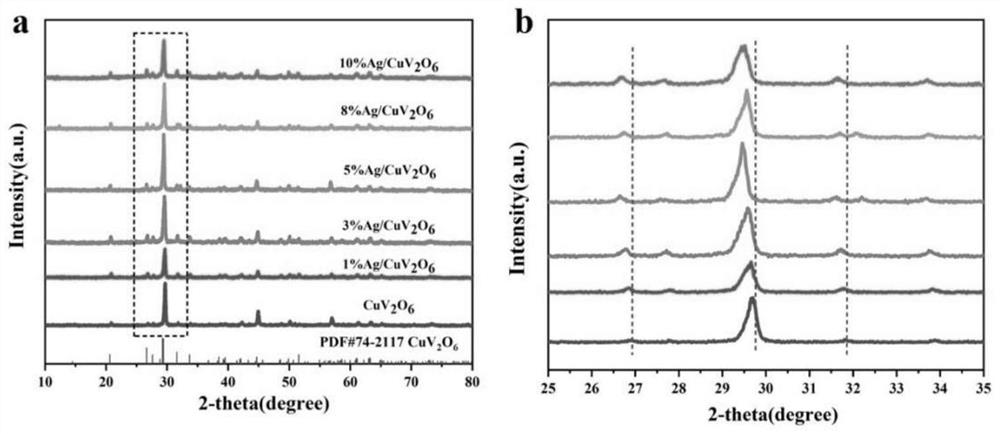

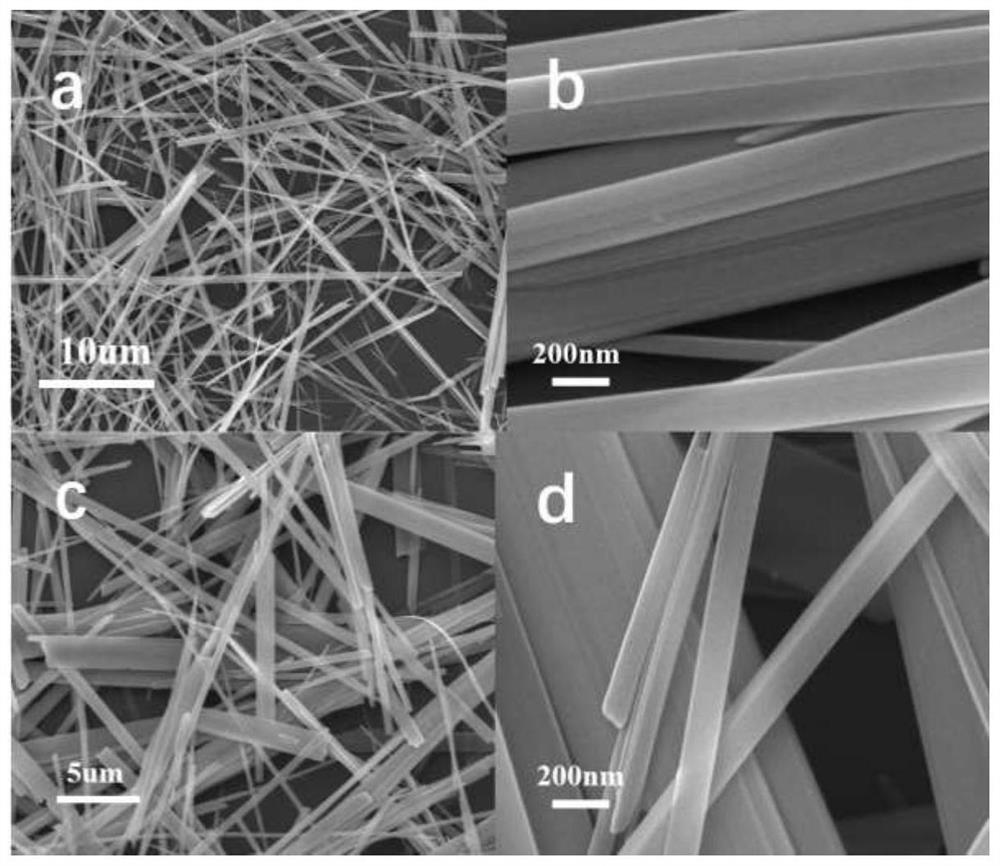

[0047] For the CuV prepared in embodiment 1 2 o 6 Some crystal structure and morphology studies were performed. Depend on figure 1 It ...

Embodiment 2

[0049] Silver doped CuV 2 o 6 Preparation of composite photocatalyst: weigh 0.402g of Cu(NO 3 ) 2 ·3H 2 Dissolve the O solid in 30ml of distilled water, stir and dissolve at room temperature until the yellow clear solution is recorded as A solution; weigh 0.303g of V 2 o 5 Disperse the solid in 30ml of pure water, stir at room temperature until the dispersion is uniform, and record it as B suspension; add B suspension to A solution drop by drop, continue stirring for 30 minutes, and record it as C suspension; adjust the pH at the same time =6. After stirring for 30 minutes, add different amounts of 0.1M silver nitrate solution, which is recorded as D solution, and continue stirring for 30 minutes. The C solution was transferred to a 100ml reaction kettle, and the reaction kettle was placed in an oven, and reacted at a high temperature of 220° C. for 24 hours. The yellow product obtained after the reaction was washed with water and ethanol, and then transferred to a vacu...

Embodiment 3

[0050] Embodiment 3 (comparative example)

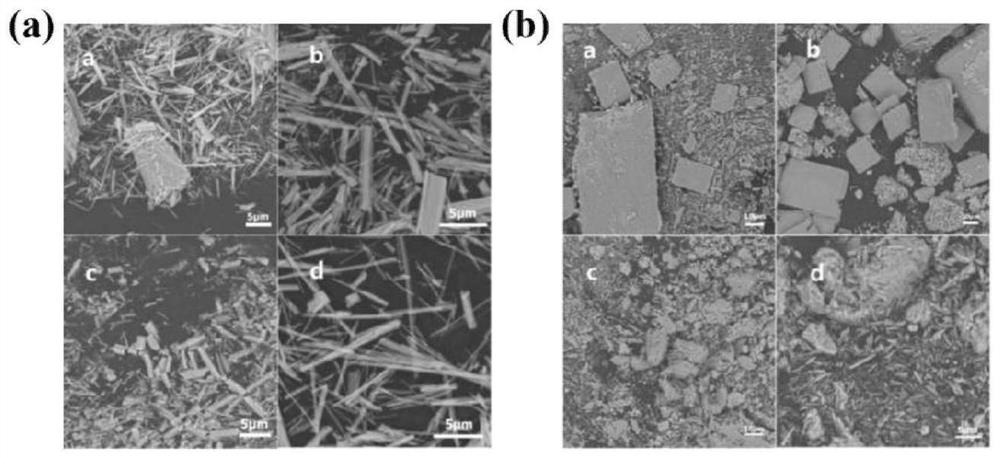

[0051] CuV 2 o 6Nanostructures were prepared under different temperature and time conditions: Weighed 0.402g of Cu(NO 3 ) 2 ·3H 2 Dissolve the O solid in 30ml of distilled water, stir and dissolve at room temperature until the yellow clear solution is recorded as A solution; weigh 0.303g of V 2 o 5 Disperse the solid in 30ml of pure water, stir at room temperature until the dispersion is uniform, and record it as B suspension; add B suspension to A solution drop by drop, continue stirring for 30 minutes, and record it as C suspension; adjust the pH at the same time =6, transfer the C suspension to a 100ml reaction kettle, place the reaction kettle in an oven, and react at a high temperature of 80-180°C for 4-16 hours. The yellow product obtained after the reaction was washed with water and ethanol, and then transferred to a vacuum drying oven at 50° C. for 6 h. The morphology of the sample prepared in Example 3 was explored to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com