A sound insulation board with micro-ventilation

A sound insulation board and micro-ventilation technology, applied in the direction of sound insulation, building components, etc., can solve the problem of lack of micro-ventilation effect, etc., and achieve the effect of sound insulation and dustproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

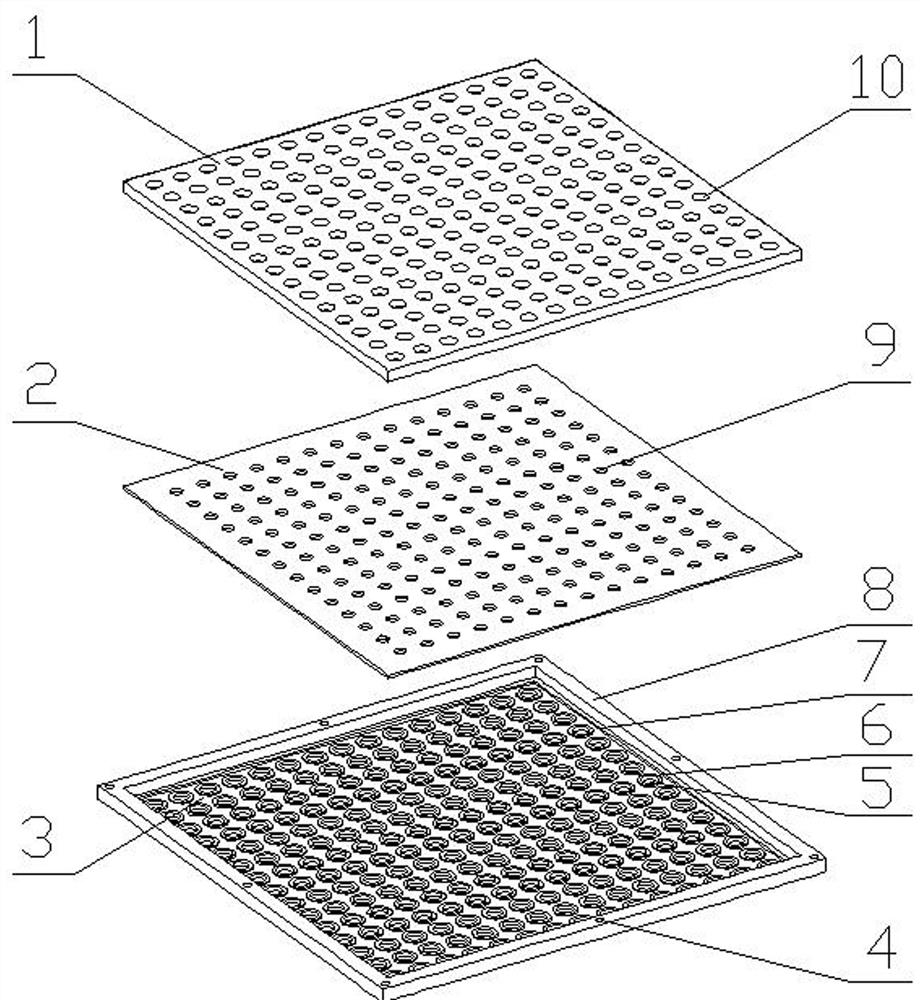

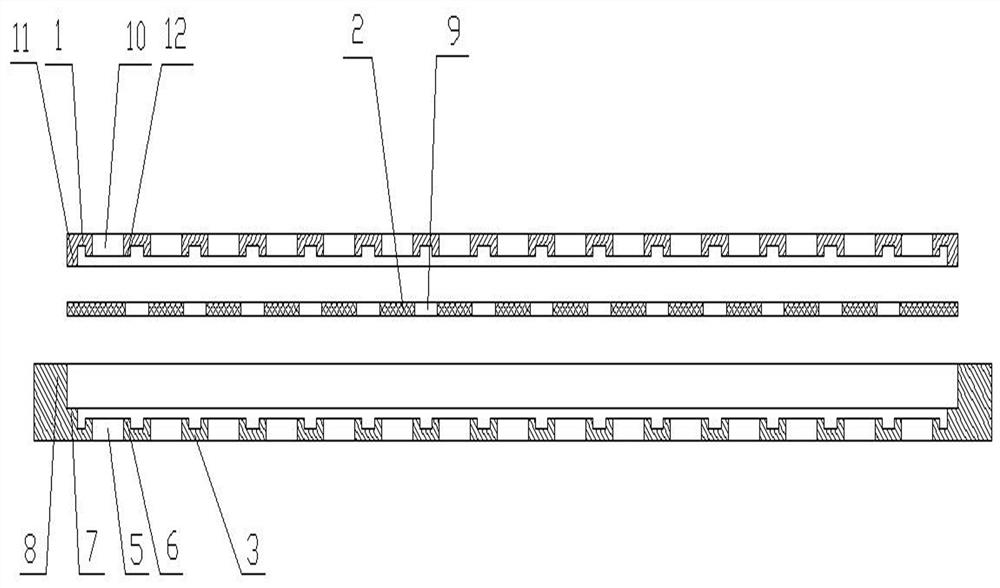

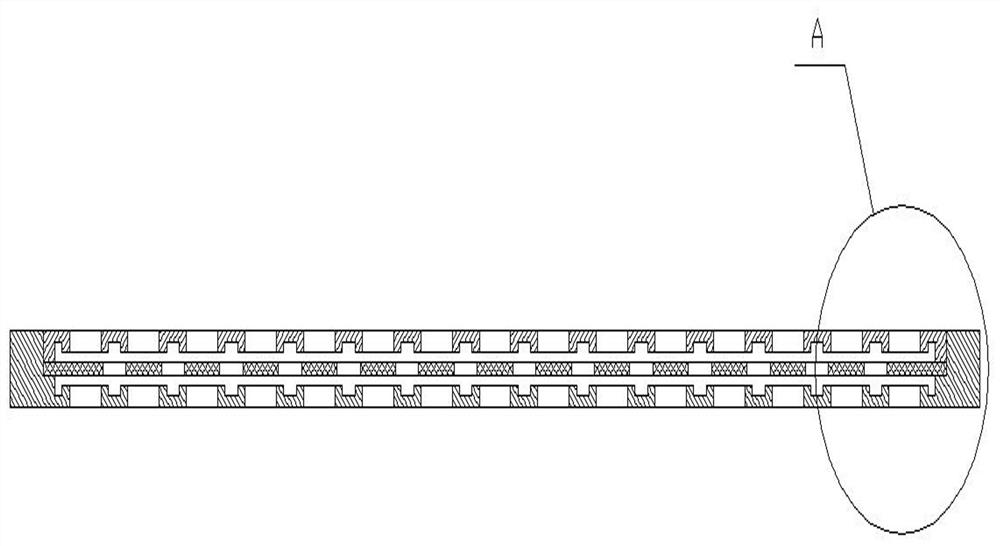

[0026] like figure 1 As shown, a sound insulation board with micro-ventilation of the present invention includes a board body 1, a board 3 and a clamping soft board 2 sandwiched between the board body 1 and the board 3. combine Figure 5-8 As shown, the board body 1, the board 3 and the clamping soft board 2 are all rectangular. A plurality of first silencing through holes 10 are spaced apart on the board body 1 , a plurality of second silencing through holes 5 are spaced apart on the plate 3 , and a plurality of ventilation holes 9 are spaced apart on the clamping flexible board 2 . The first silencing through holes 10 , the second silencing through holes 5 and the ventilation holes 9 are all evenly spaced in an array. The first silencing through hole 10 , the second silencing through hole 5 and the ventilation hole 9 are all circular holes or hexagonal holes.

[0027] Board body 1 and board 3 are pressed by a mixture of polypropylene short fibers, wood fibers, Portland c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com