Method for calculating surface roughness of workpiece during turning based on tool wear

A technology for workpiece surface and tool wear, applied in complex mathematical operations and other directions, can solve the problem of not considering the influence of workpiece surface roughness, etc., and achieve the effect of improving surface quality, simple calculation method and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

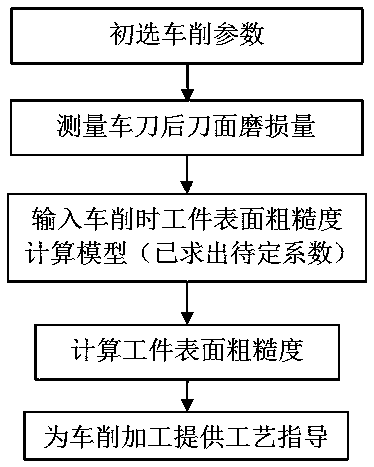

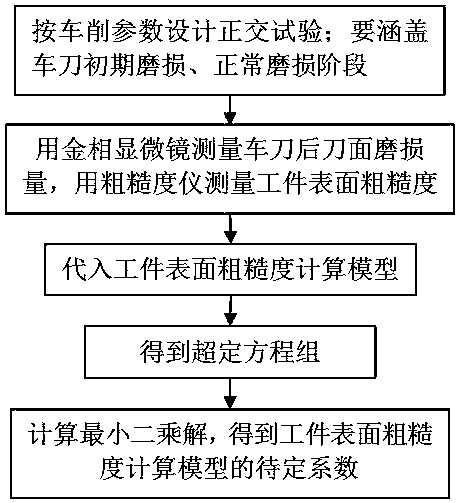

[0018] Combine below figure 1 figure 2 The present invention is further described in detail.

[0019] In step 1), based on the metal cutting theory, according to the relationship between the turning parameters and the surface roughness of the workpiece, and considering the influence of tool wear on the surface roughness of the workpiece, a calculation model for the surface roughness of the workpiece during turning is established:

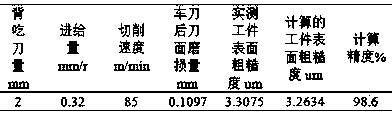

[0020] R a =k×a p a × f b ×V c ×VB d (1)

[0021] Among them, R a is the workpiece surface roughness; VB is the flank wear amount of the turning tool, which is the characteristic value of the tool wear condition; a p Is the amount of back cut; f is the feed; V is the cutting speed; k, a, b, c and d are undetermined coefficients.

[0022] In step 2), use the roughness meter and metallographic microscope to measure and calculate the undetermined coefficients in the calculation model of the surface roughness of the workpiece during turning....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com