Folding three-phase transformer and manufacturing method thereof

A technology of three-phase transformers and manufacturing methods, which is applied in the direction of inductance/transformer/magnet manufacturing, transformers, transformer/inductance parts, etc., can solve the problems of impracticability, complex manufacturing process of three-phase symmetrical transformers, etc., and achieve reduction of materials, The effect of lowering the temperature and facilitating lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

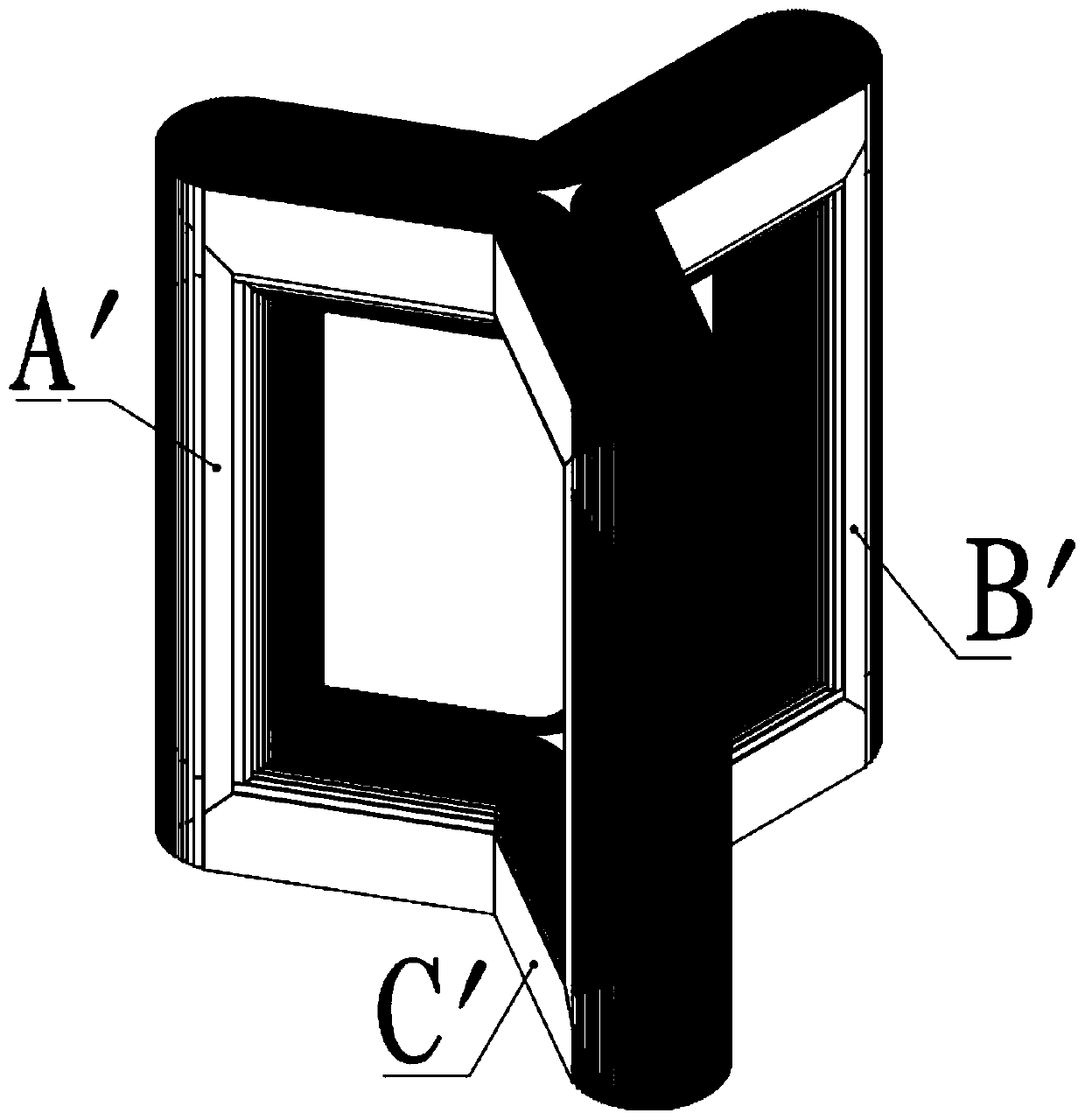

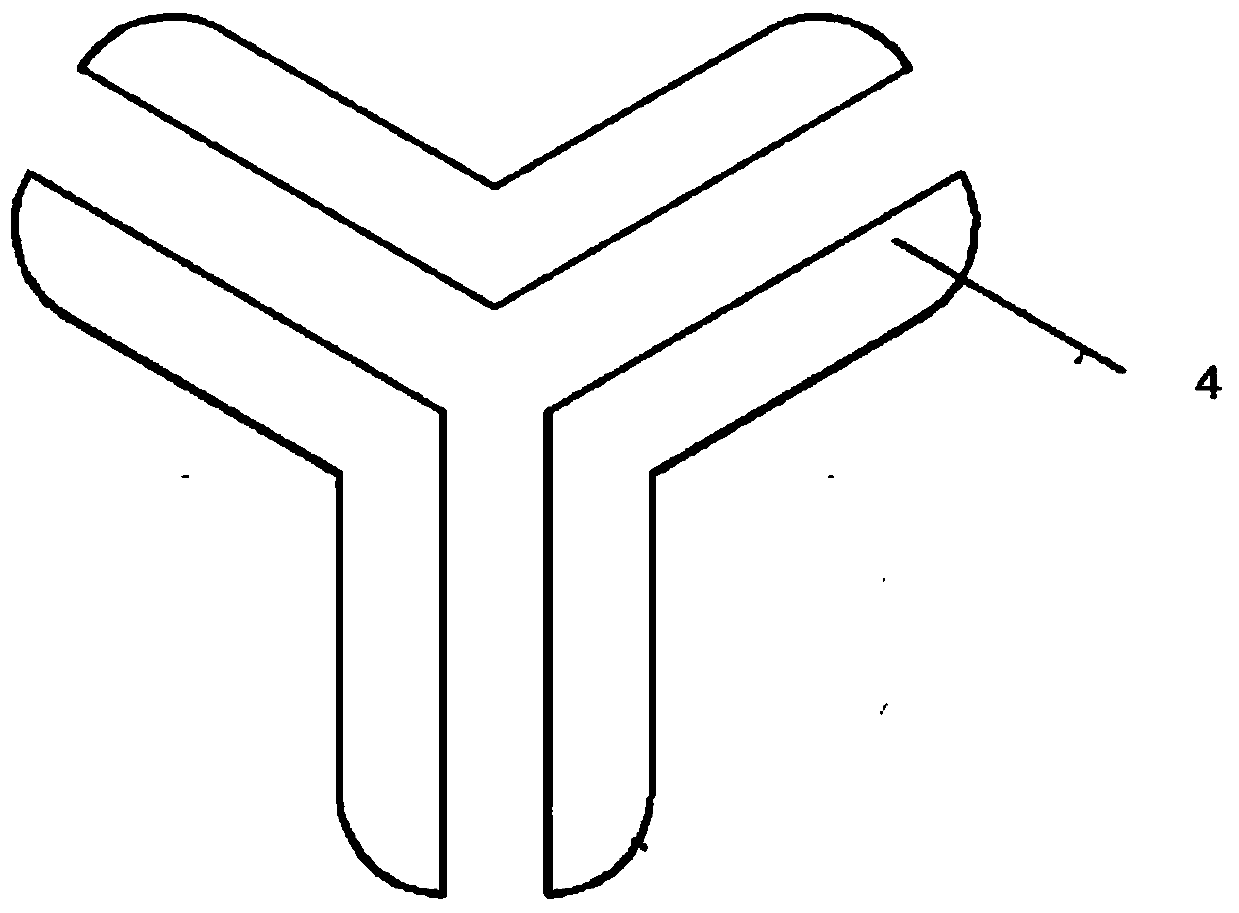

[0033] See ( figure 1 ), a folded three-phase transformer consisting of three core legs ( figure 1 ), the upper iron yoke and the lower iron yoke, the iron core columns have three vertical ones respectively, arranged at the three vertices of an equilateral triangle, such as ( Figure 4 ), the iron yoke is a connecting iron core connecting three iron core columns, such as ( figure 1 ) is divided into upper iron yoke and lower iron yoke. The axis direction of the iron core columns is connected in a star shape along the center line of the iron yoke. 120 degrees to each other in a plane.

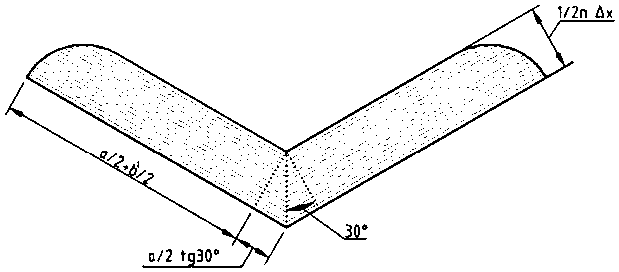

[0034] Such as( figure 1 , image 3 , Figure 4 ), the iron core column is formed by stacking several iron chips vertically.

[0035] The iron yoke unit ( Figure 4 ) is formed by folding a number of core iron sheets horizontally.

[0036] The iron core post iron shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com