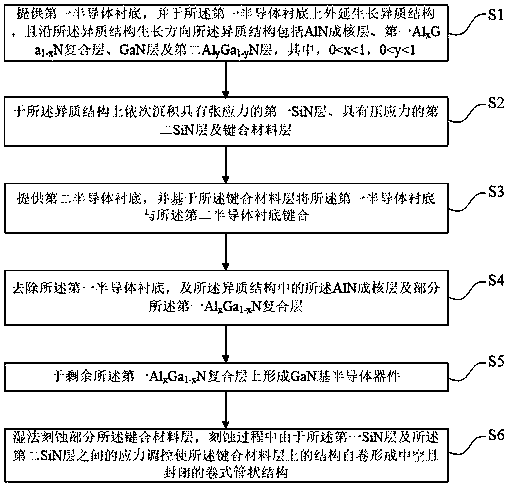

Roll-type GaN-based semiconductor device and preparation method thereof

A semiconductor and device technology, applied in the field of roll-type GaN-based semiconductor devices and their preparation, can solve the problems of increasing process complexity and difficulty in downsizing, and achieve the effect of ensuring heat dissipation performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

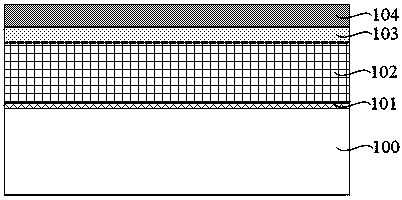

[0043] This embodiment provides a method for preparing a roll-type GaN-based semiconductor device. By forming a SiN layer with tensile stress and a SiN layer with compressive stress, and then cooperate with the process of etching to remove part of the bonding material layer, during the etching process , the two SiN layers with different stresses (tensile stress and compressive stress) are mutually regulated so that the entire semiconductor device is self-rolled into a hollow and closed roll-type tubular structure. This three-dimensional structure meets the small size requirements of the device; at the same time, The GaN-based semiconductor device (rolled tubular structure) formed by self-rolling can be used as a microfluidic channel naturally, without additional post-process for microfluidic channel processing, the process is simple and can ensure the heat dissipation performance of the semiconductor device; moreover, when the semiconductor device is applied Under high temperat...

Embodiment 2

[0071] This embodiment provides a roll-type GaN-based semiconductor device. The semiconductor device can be prepared by the preparation method of the first embodiment above, but is not limited to the preparation method described in the first embodiment, as long as the structure of the semiconductor device can be formed. For the beneficial effects achieved by the semiconductor device, please refer to Embodiment 1, which will not be described in detail below.

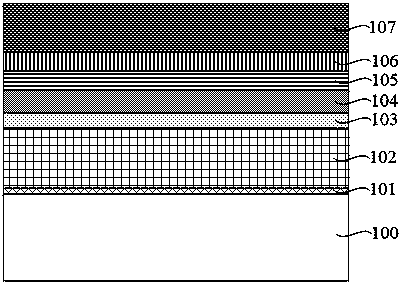

[0072] Such as Figure 8 As shown, the semiconductor device includes:

[0073] a second semiconductor substrate 108;

[0074] a bonding material layer 107 located on the second semiconductor substrate 108;

[0075] A hollow and closed rolled tubular structure 113 is located on the bonding material layer 107. The rolled tubular structure 113 sequentially includes: a second SiN layer 106 with compressive stress, and a first SiN layer with tensile stress. layer 105, the second AlyGa1-yN layer 104, the GaN layer 103 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com