High-voltage transmission line inspection robot with multiple motion modes

A high-voltage transmission line, multi-motion mode technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficulty in crossing obstacles, weak climbing ability, slow traveling speed, etc., to achieve fast traveling speed, strong climbing ability, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the drawings:

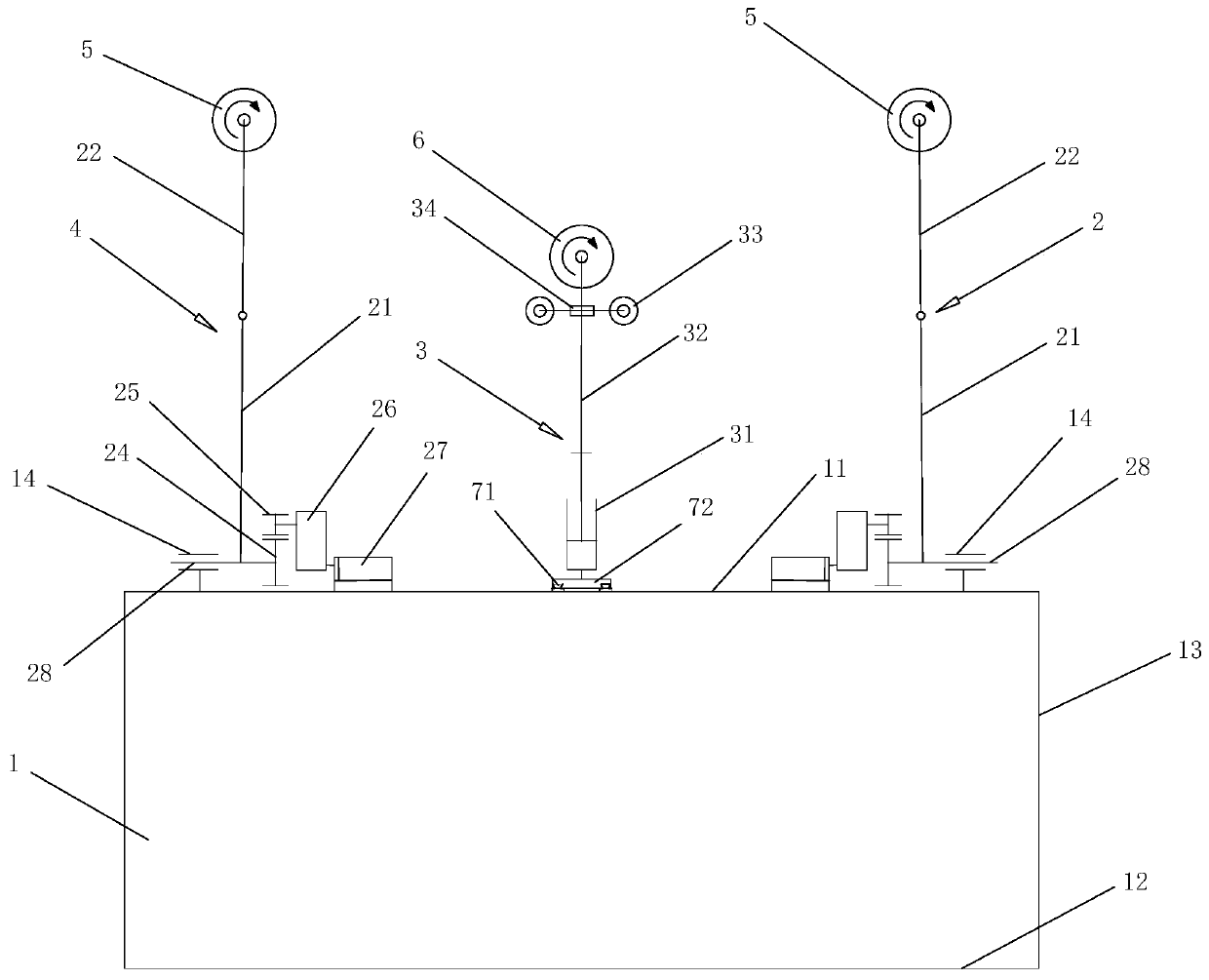

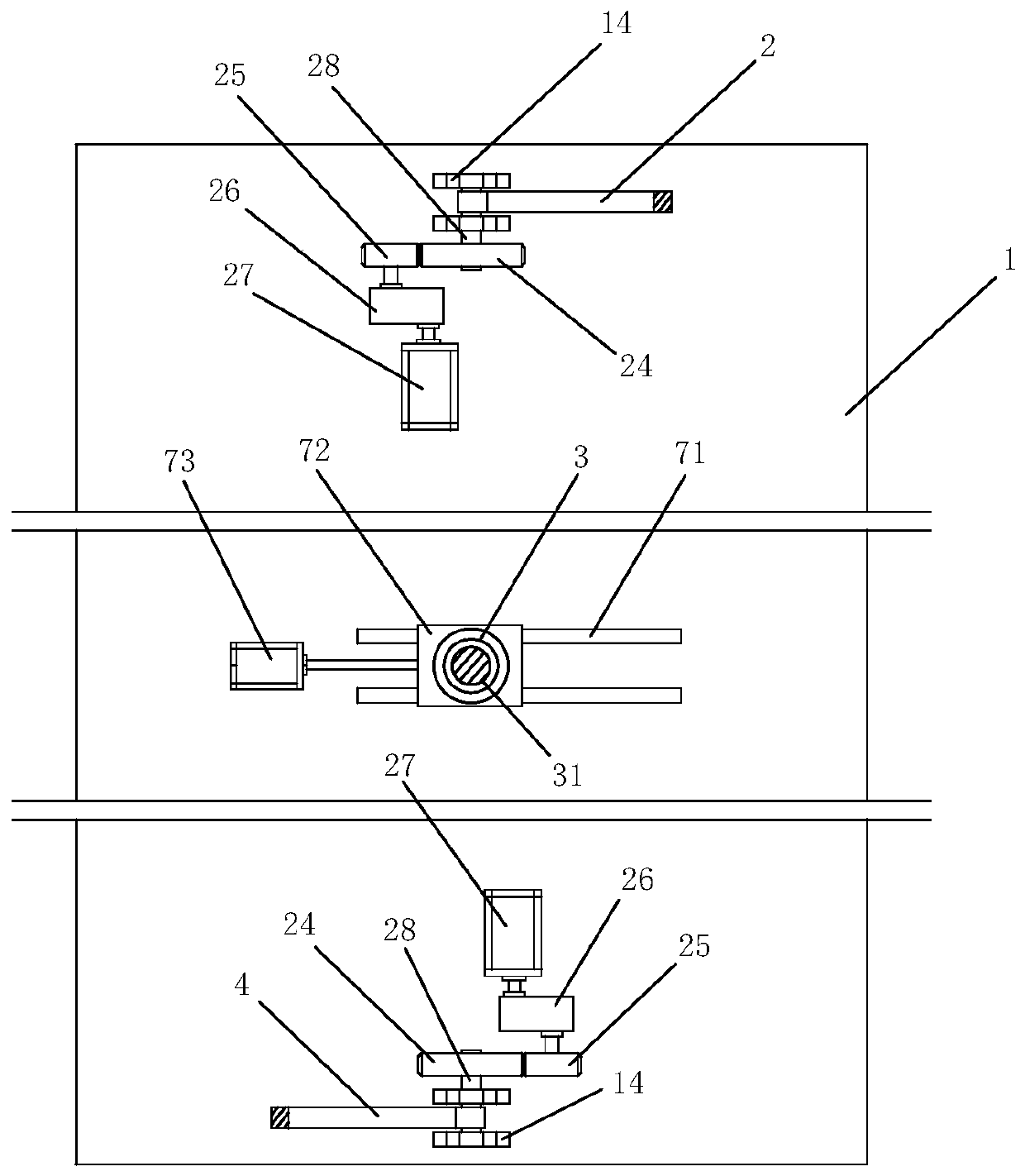

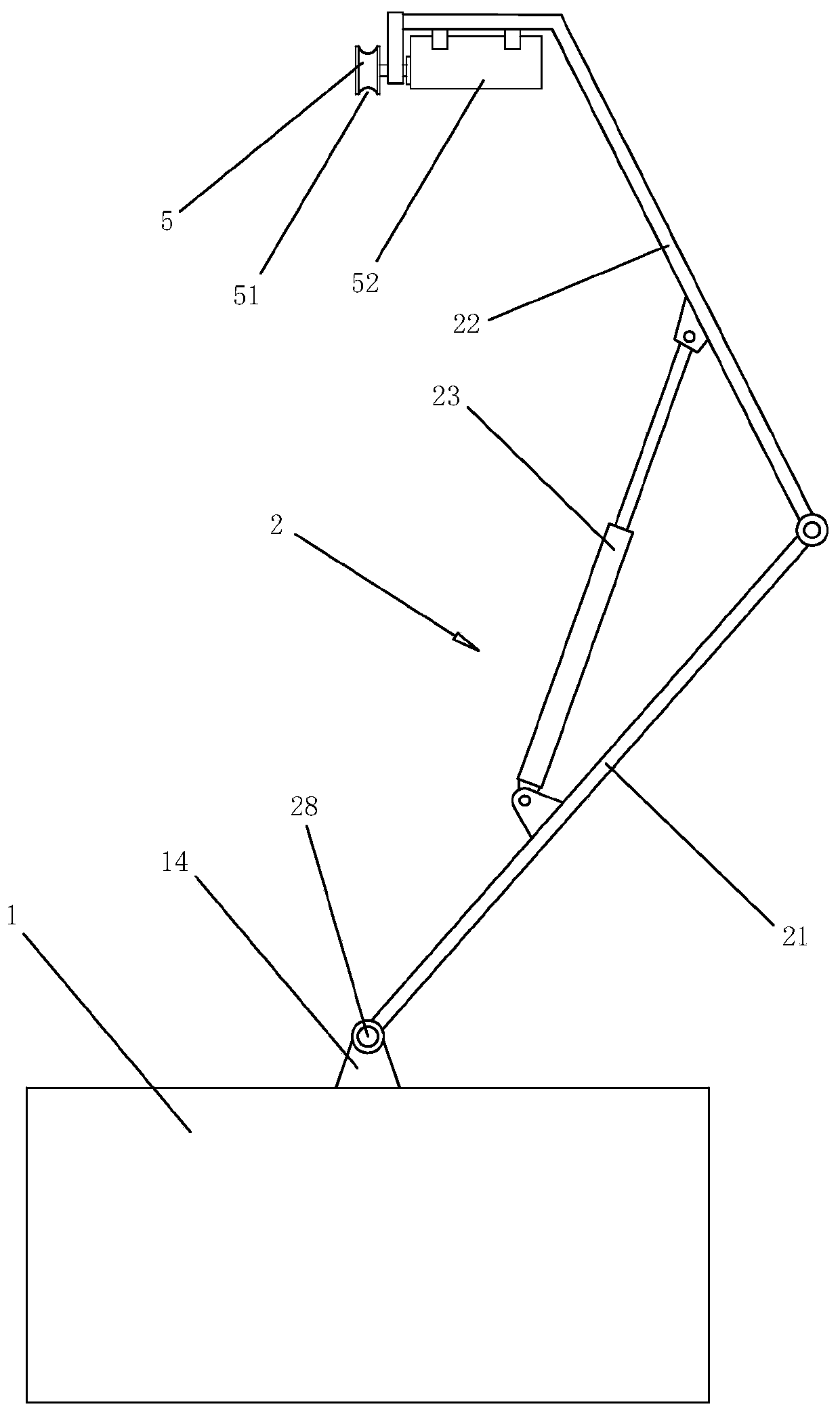

[0044] Combine Figure 1 to Figure 13 , A multi-motion mode high-voltage transmission line inspection robot, including a box body 1, a front robot arm 2, a middle robot arm 3, a rear robot arm 4 and a control system. The box body includes a top plate 11, a bottom plate 12 and four side plates 13. The top plate 11, the bottom plate 12 and the four side plates 13 are welded into a square box structure.

[0045] A hinge support 14 is fixedly welded on the front side and the rear side of the top of the box body 1 respectively, and the hinge support 14 is provided with a shaft hole. The front manipulator 2, the middle manipulator 3, and the rear manipulator 4 are sequentially spaced from the front to the back above the box body 1. The front manipulator 2, the middle manipulator 3, and the rear manipulator 4 are all telescopic mechanical arms. Specifically, the lower end of the front robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com