Network compensation controller heat dissipation device

A network compensation and heat dissipation device technology, applied in chemical instruments and methods, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of radiator overheating, single heat dissipation effect, and poor heat dissipation of the controller, etc. Achieve the effect of improving heat dissipation, good heat dissipation effect, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

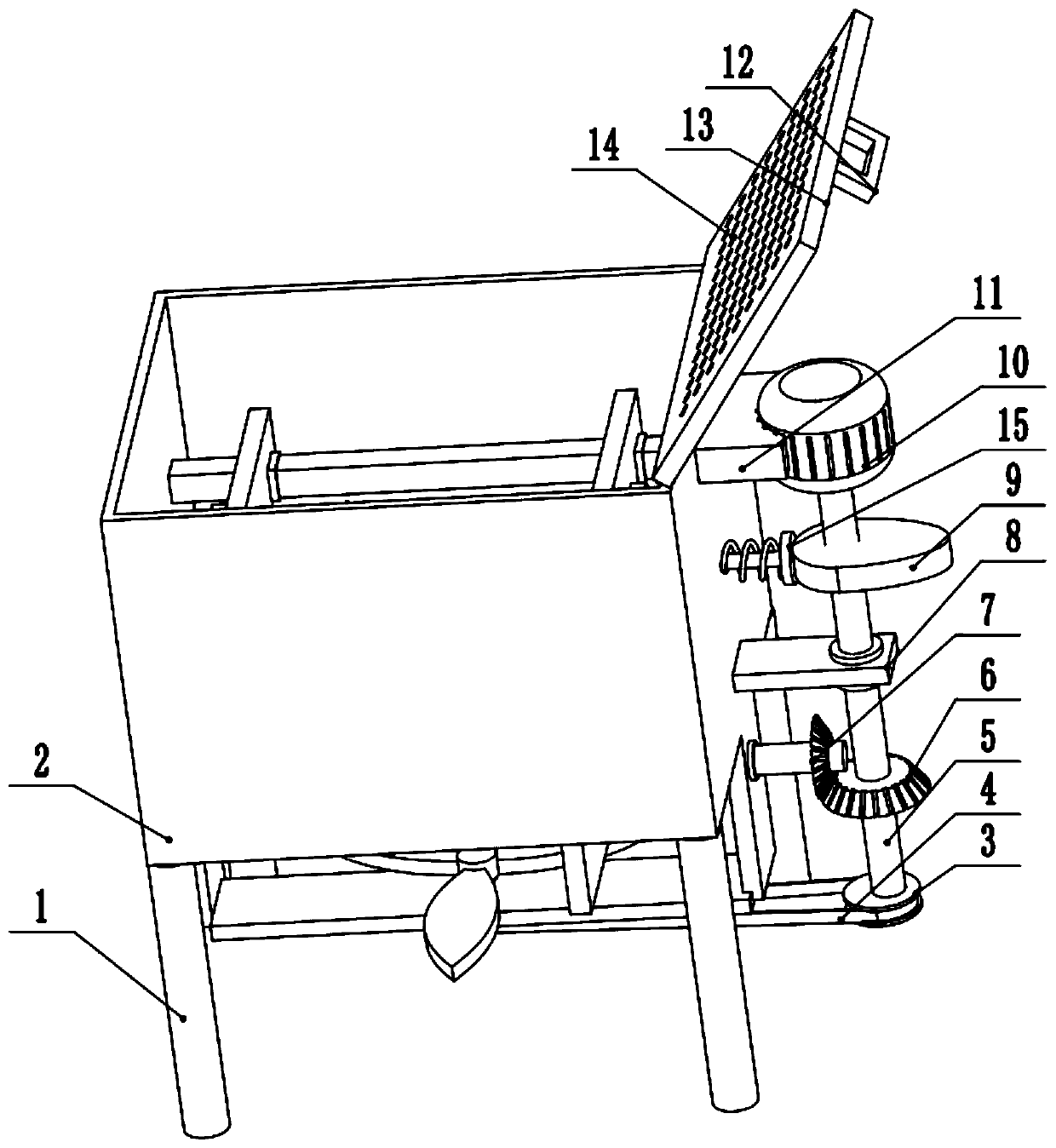

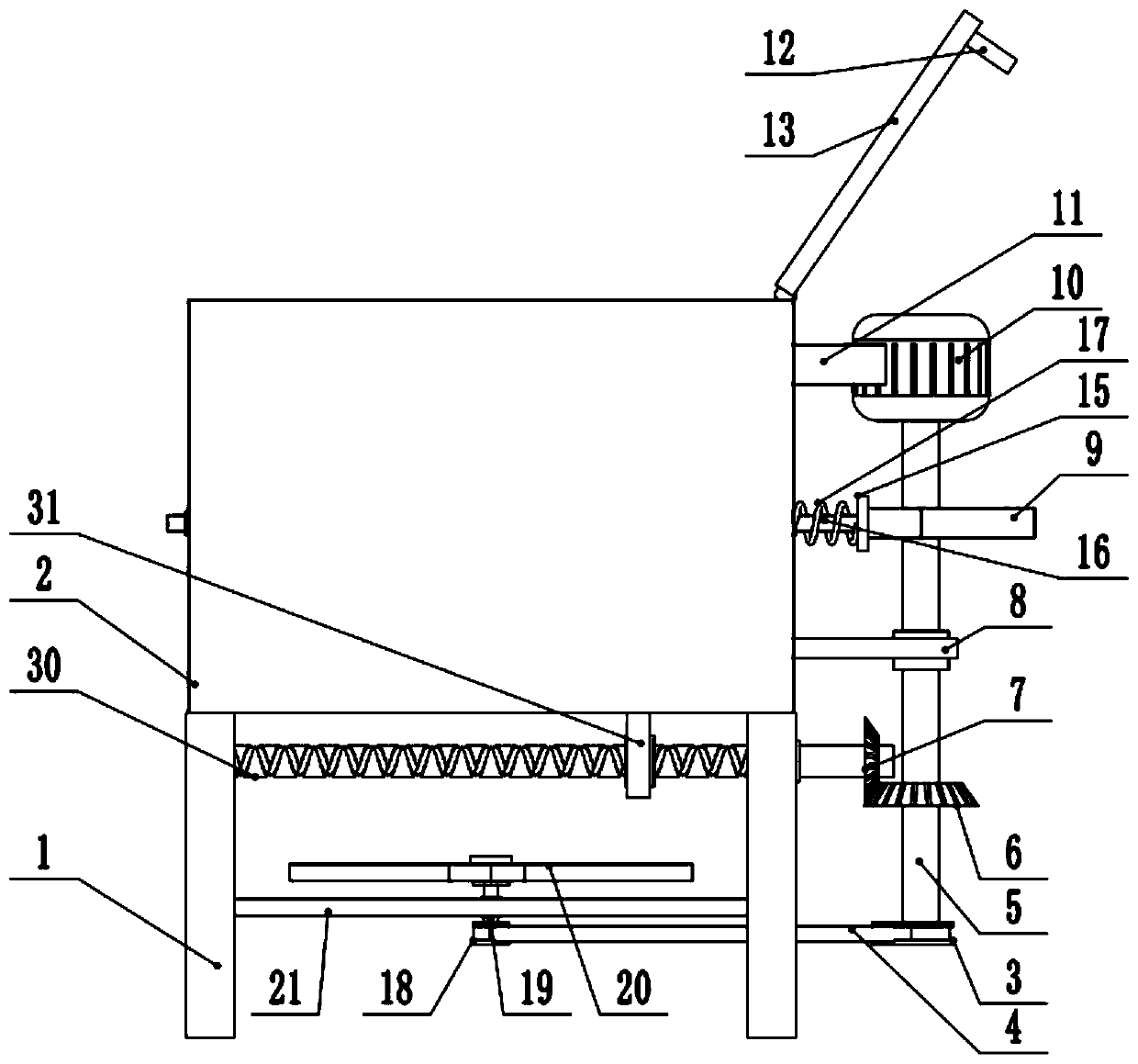

[0028] see Figure 1-4 , a network compensation controller cooling device, including a box 2, the lower surface of the box 2 left and right sides are provided with table legs 1, the bottom of the box 2 is provided with an air inlet 22, the top of the box 2 rotates on the right Connect the baffle plate 13, the middle part of the baffle plate 13 is provided with an air vent 14, the end of the baffle plate 13 is provided with a handle 12, the upper part of the right side wall of the box body 2 is provided with a driving motor 10, and the right side wall of the box body 2 The top is provided with a motor holder 11, the right side of the motor holder 11 is fixedly connected to the drive motor 10, the output shaft of the drive motor 10 is fixedly connected to the upper end of the rotating shaft 5, the right side wall bottom of the box body 2 is provided with a fixed plate 8, the fixed plate The right side of 8 rotates and connects the middle part of rotating shaft 5, and the top of ...

Embodiment 2

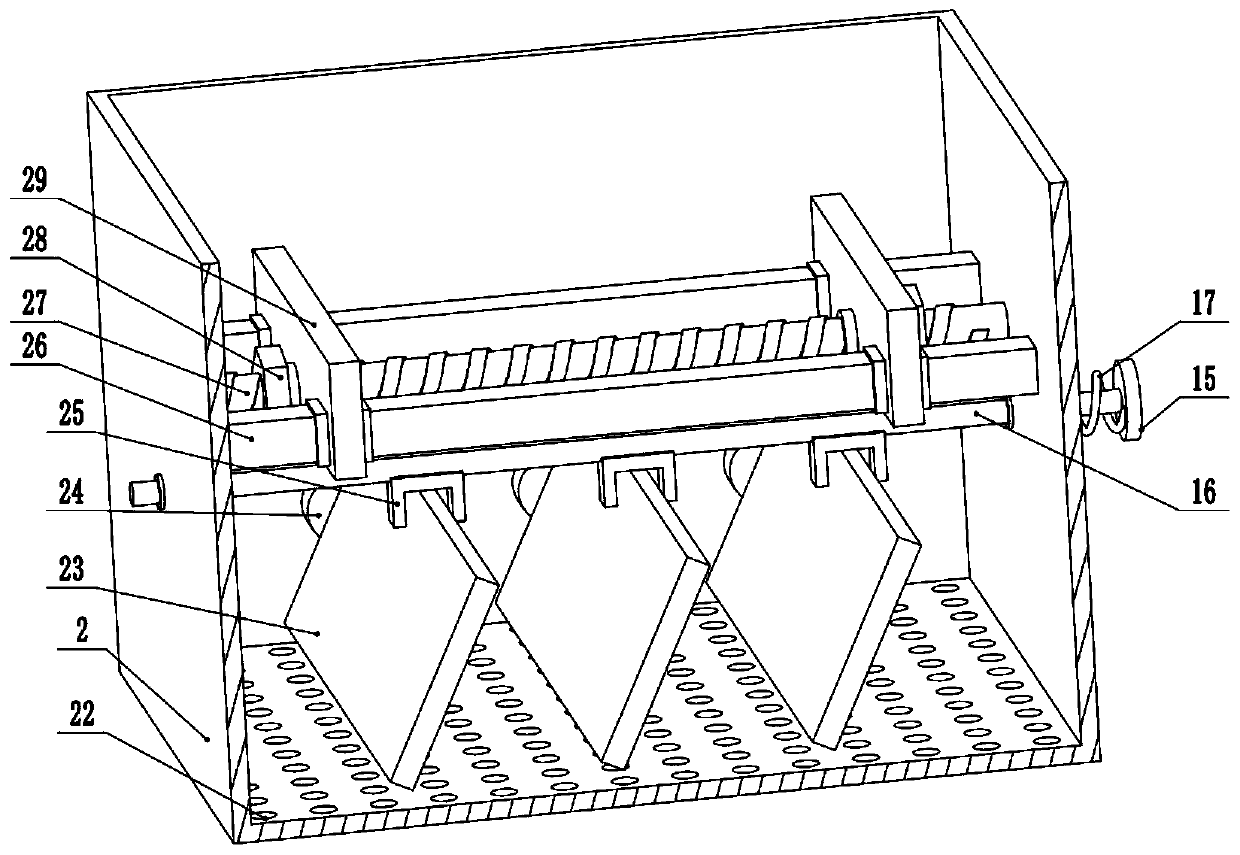

[0031] see image 3 and Figure 4 , the other content of this embodiment is the same as Embodiment 1, the difference is that: the left and right sides of the support rod 26 are slidably connected to the clamping plate 29, the top of the box body 2 is provided with a first screw rod 27, the first wire The left and right sides of the rod 27 run through and connect the lower part of the clamping plate 29 , and the left and right ends of the first screw rod 27 are provided with fastening nuts 28 . When the device is in normal use, the controller can be directly placed on the support rod 26. At this time, the controller is in a suspended state, so as to better dissipate heat. However, due to the different models of the controllers, the sizes of the controllers are different, so In the future, the controller can be better fixed in this device, and the clamping plate 29 is set on the upper part of the device, and the first screw rod 27 and the fastening nut 28 are used to fix the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com