Sectional type central heating element of heating incombustible cigarette

A heating-not-burning and heating element technology, applied in the direction of tobacco, etc., can solve the problems of high smoke diffusion resistance, high requirements for temperature measurement and temperature control circuits, and increase the cost of smoking sets, so as to solve the problem of uneven smoke volume and improve heating uniformity , Improve the effect of mouth-to-mouth consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

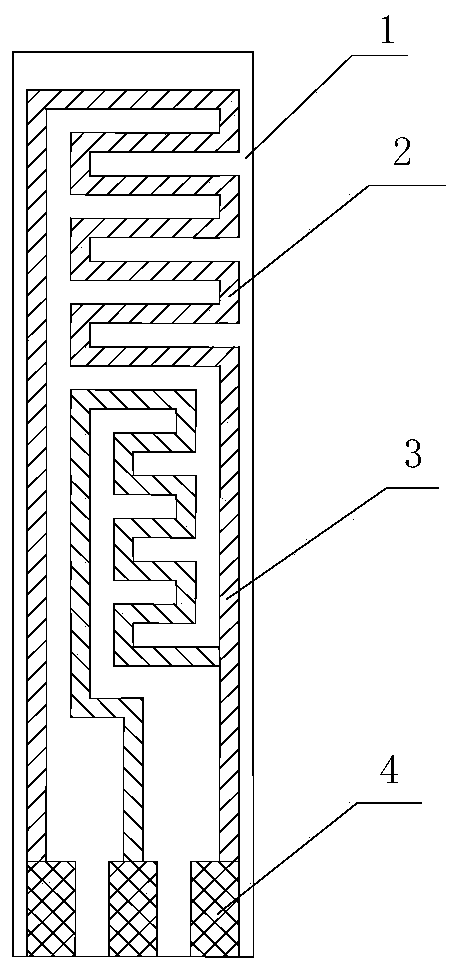

[0028] The heating element is shaped like figure 2 shown.

[0029] The first heating track (2), the second heating track (3) and the welding pad (4) are fixed on the same side outer surface of the sheet-shaped substrate (1) made of zirconia ceramic material by printing and sintering process; the first heating track Both (2) and the second heating track (3) use platinum (Pt)-based conductive materials. The total length of the heating track is 42mm.

Embodiment 2

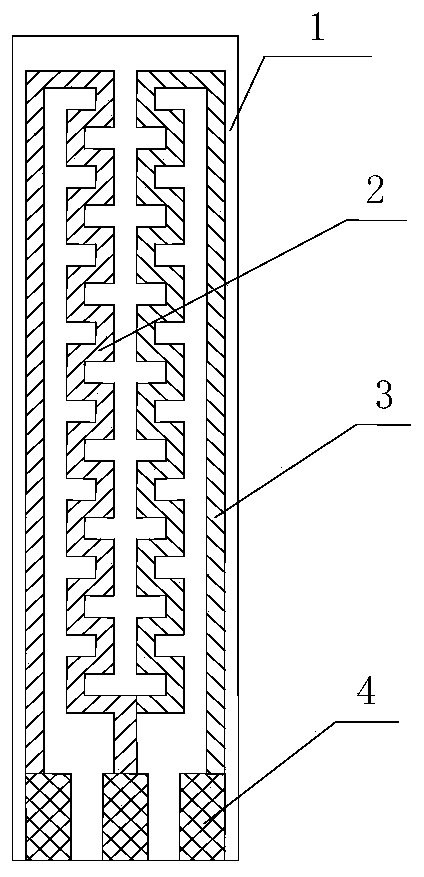

[0031] The heating element is shaped like image 3 shown.

[0032] The first heating track (2), the second heating track (3) and the welding pad (4) are fixed on the same side outer surface of the sheet-shaped substrate (1) made of zirconia ceramic material by printing and sintering process; the first heating track Both (2) and the second heating track (3) use platinum (Pt)-based conductive materials. The total length of the heating track is 42mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com