Chemical production equipment and using method

A chemical production and equipment technology, applied in the field of chemical production equipment, can solve the problems of volatilization of raw materials and inability to realize continuous production, so as to avoid pollution or loss and improve the efficiency of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

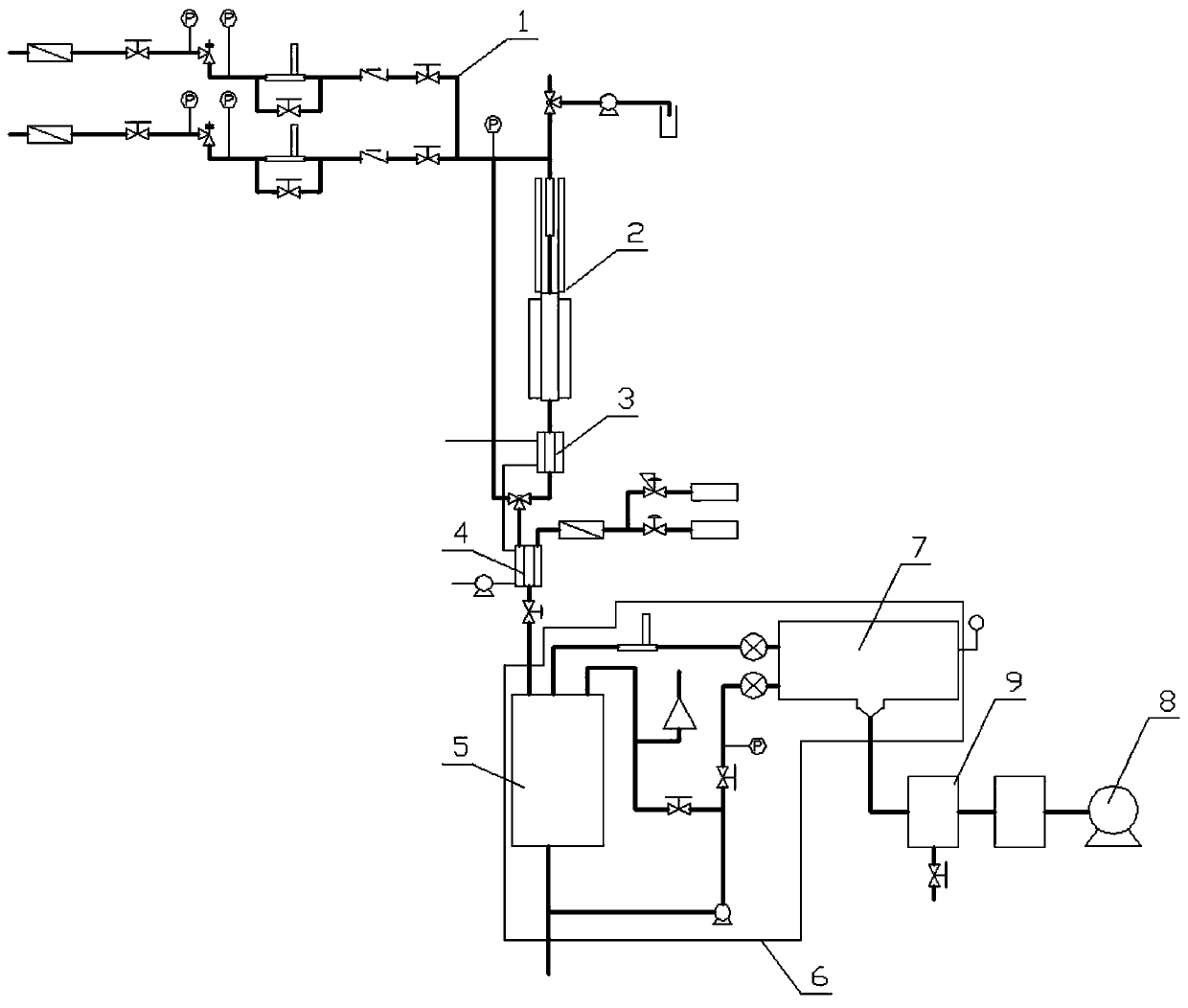

[0033] Such as figure 1 as shown, figure 1 It is a structural view of the chemical production equipment; the chemical production equipment of the present invention includes a fixed bed reaction device and a dehydration device, and the fixed bed reaction device and the dehydration device are directly connected through a conduit.

[0034] Specifically, the fixed-bed reactor includes at least two input pipelines 1, a reaction furnace 2, a first condenser 3 and a collector 4, the input pipeline 1 is connected with the inlet of the reaction furnace 2, and the reaction furnace 2 The outlet of the outlet is connected with the collector 4 through the first condenser 3, and the reaction substance is input into the reaction furnace 2 through the input pipe 1 and reacted, liquefied by the condensation effect of the first condenser 3 and Collect in the collector 4, the outlet of the collector 4 is connected with the inlet of the dehydration device.

[0035] The dehydration device includ...

Embodiment 2

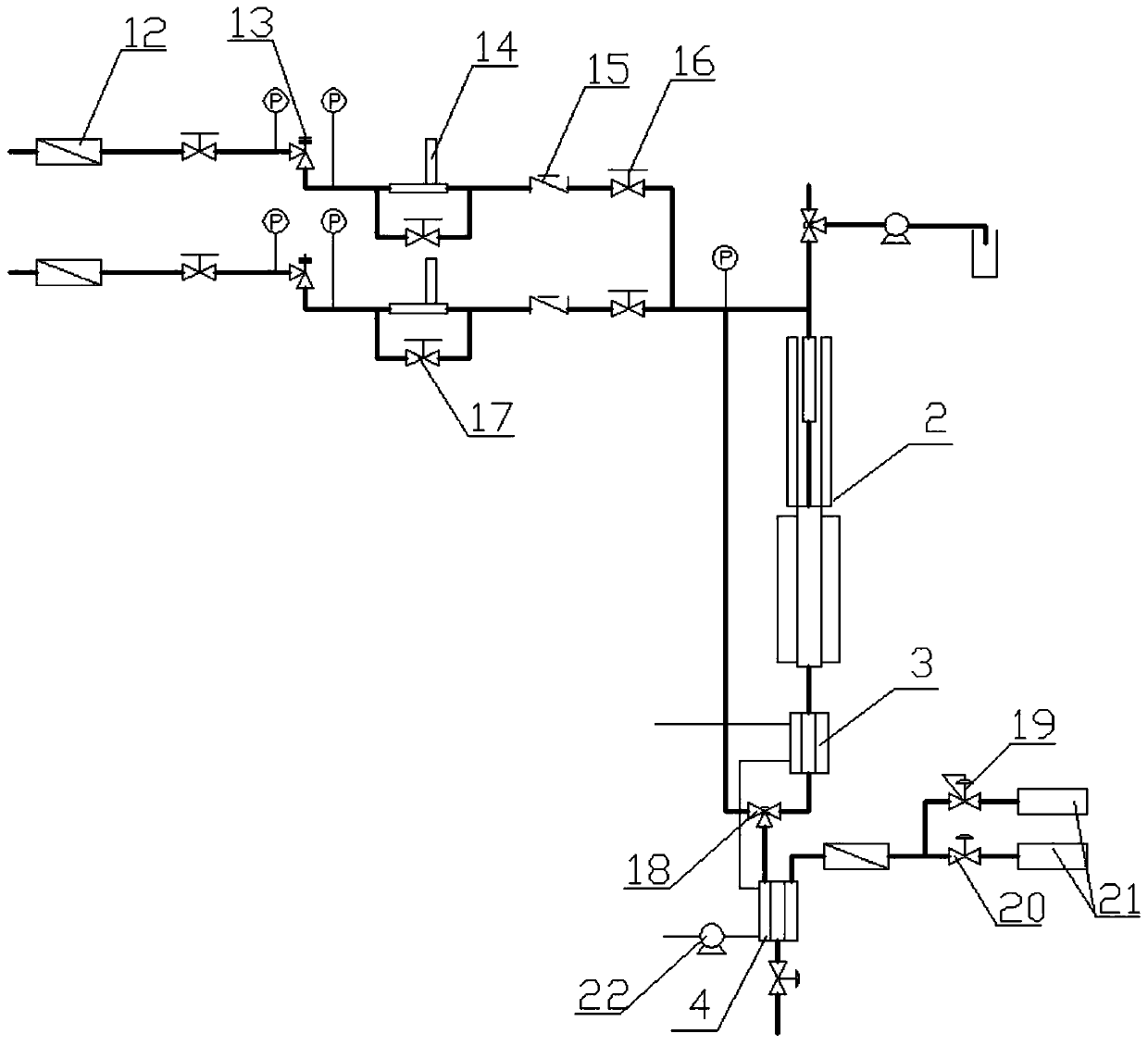

[0039] Such as figure 2 as shown, figure 2It is a structural view of the fixed bed reactor; the input pipeline 1 is provided with a filter 12, a switch valve, a pressure reducing valve 13, a flow meter 14, and a one-way valve 15, and the filter 12 is used for filtering the transported There are several on-off valves, among which the first on-off valve 16 is used to control the opening or closing of a single input pipe 1 as a whole, and the second on-off valve 17 and the flow meter 14 are arranged in parallel. The second on-off valve 17 allows the reactant to pass only through the pipeline section provided with the flow meter 14 , so that the flow of the reactant in the input pipeline 1 can be accurately measured. By opening the second on-off valve 17 , to realize the rapid passage of the reactant substance, the one-way valve 15 is used to avoid the reflux of the reactant substance in the input pipeline 1, and the pressure reducing valve 13 is used to adjust the pressure in ...

Embodiment 3

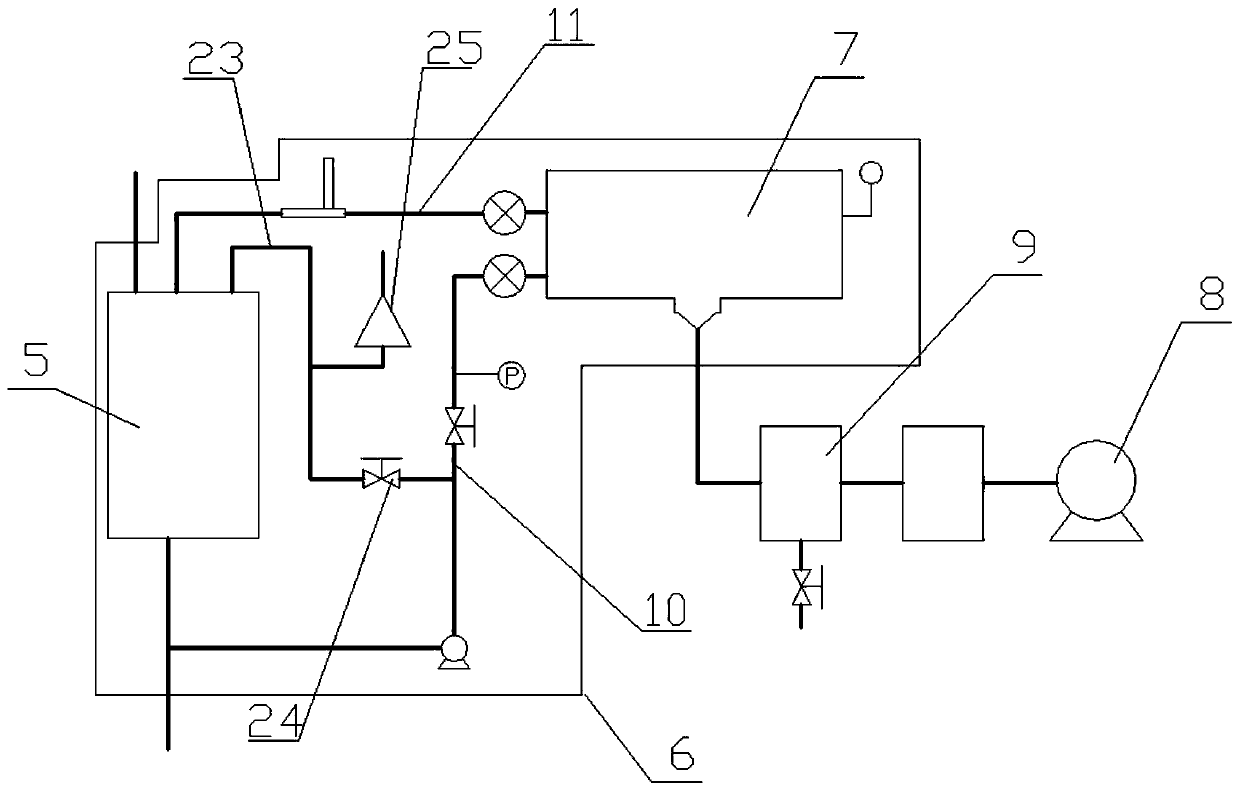

[0046] Such as image 3 as shown, image 3 It is a structural view of the dehydration device; the inlet pipe 10 and the outlet pipe 11 are provided with thermometers near the ends of the membrane module 7 for real-time detection of the temperature of the raw materials entering and leaving from the membrane module 7 .

[0047] The inlet pipe 10 is provided with a pressure gauge for detecting the pressure state of the inlet pipe 10 .

[0048] The inlet pipe 10 is connected to the raw material tank 5 through a return pipe 23, and the return pipe 23 is provided with a return valve 24. When the pressure of the inlet pipe 10 is too high, the return valve 24 is activated to realize the Rapid depressurization of inlet pipe 10. Preferably, the return pipe 23 is also provided with an exhaust valve 25, through which the gas can be quickly discharged due to excessive pressure caused by gasification during the heating process.

[0049] Generally, the connecting ports of the return pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com