Cutting device for machining solid wood furniture

A cutting device and furniture technology, applied in wood processing appliances, manufacturing tools, forming/shaping machines, etc., can solve problems such as deviation and sheet sliding cutting accuracy, and achieve the effect of convenient cutting and avoiding the impact of cutting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

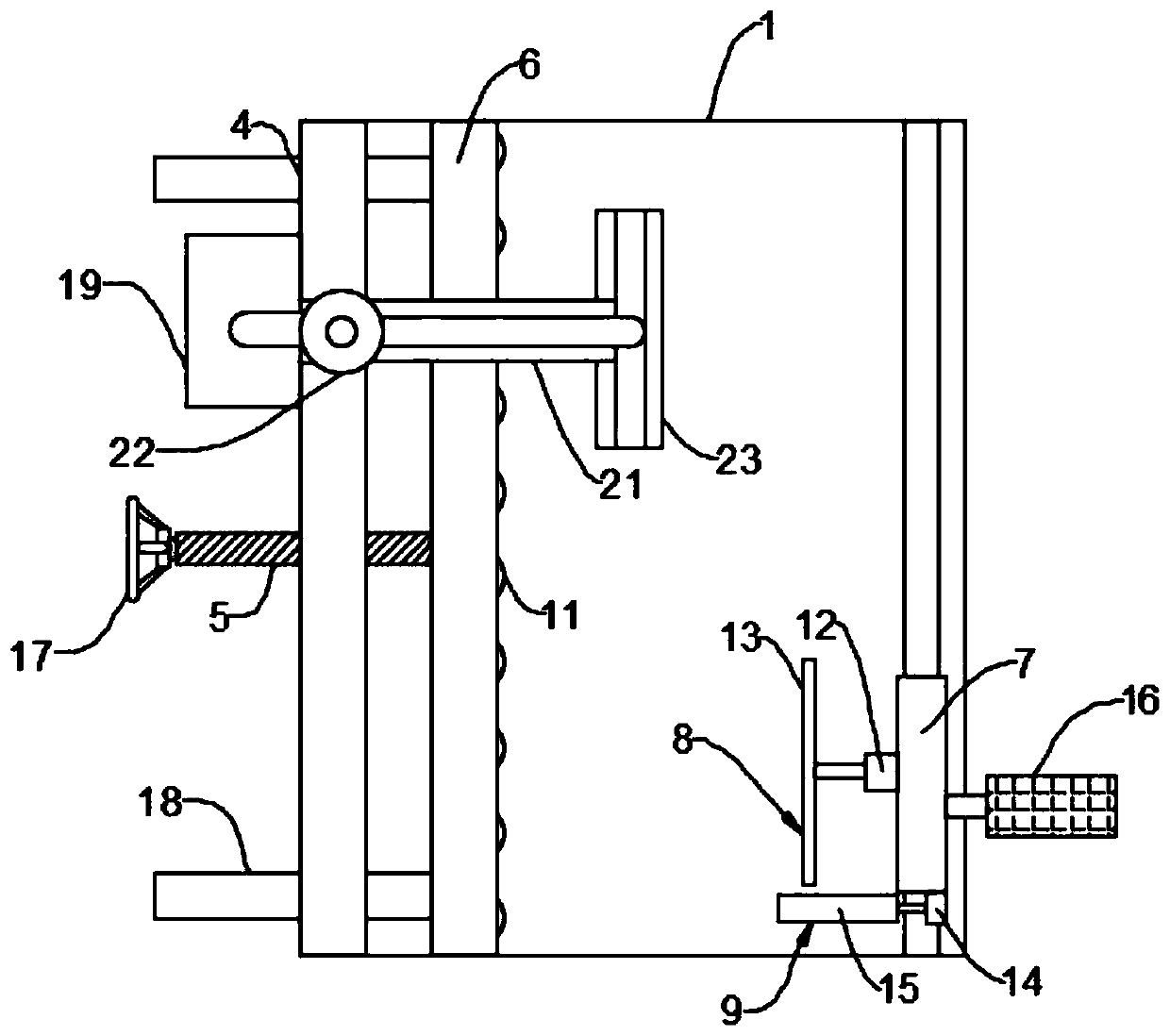

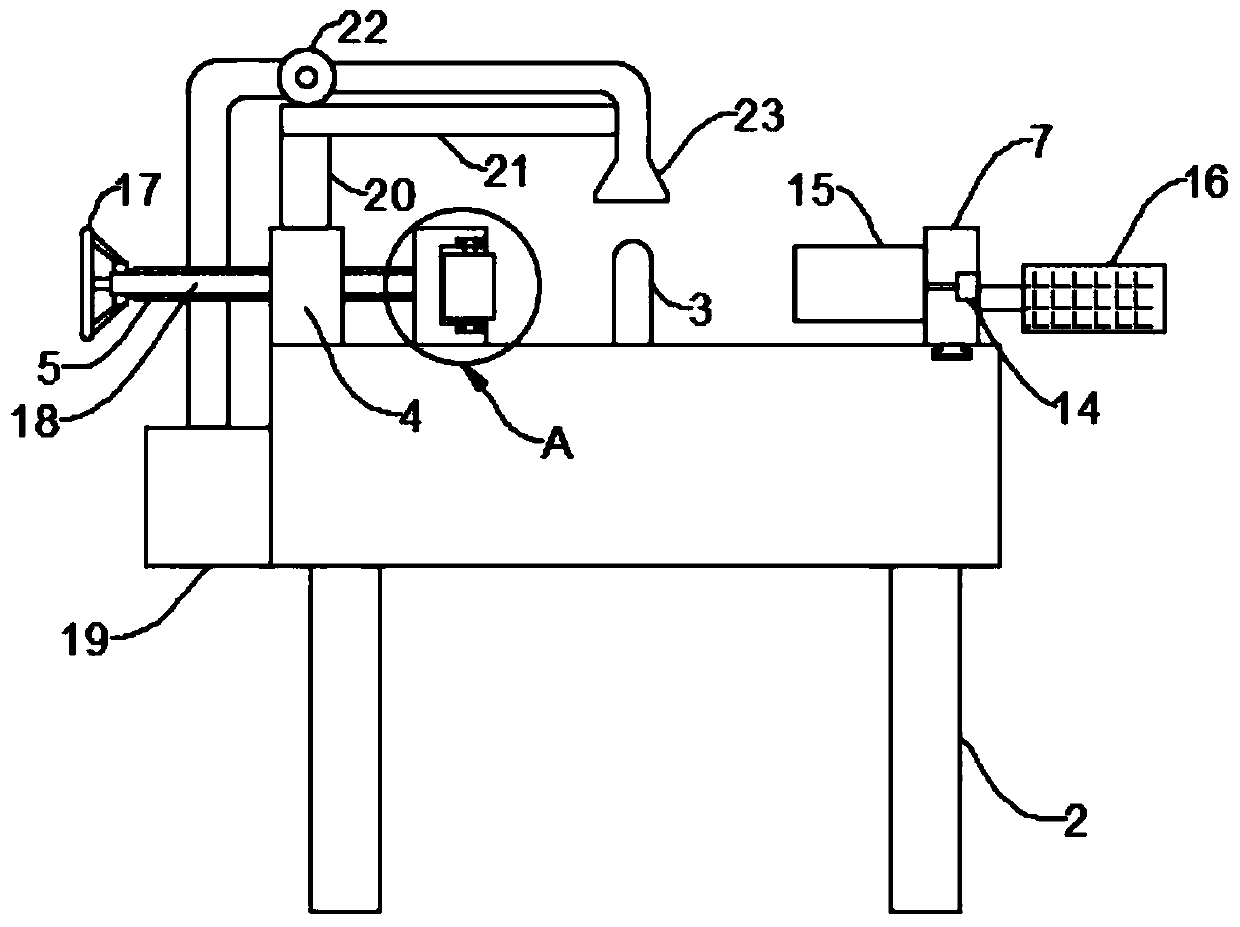

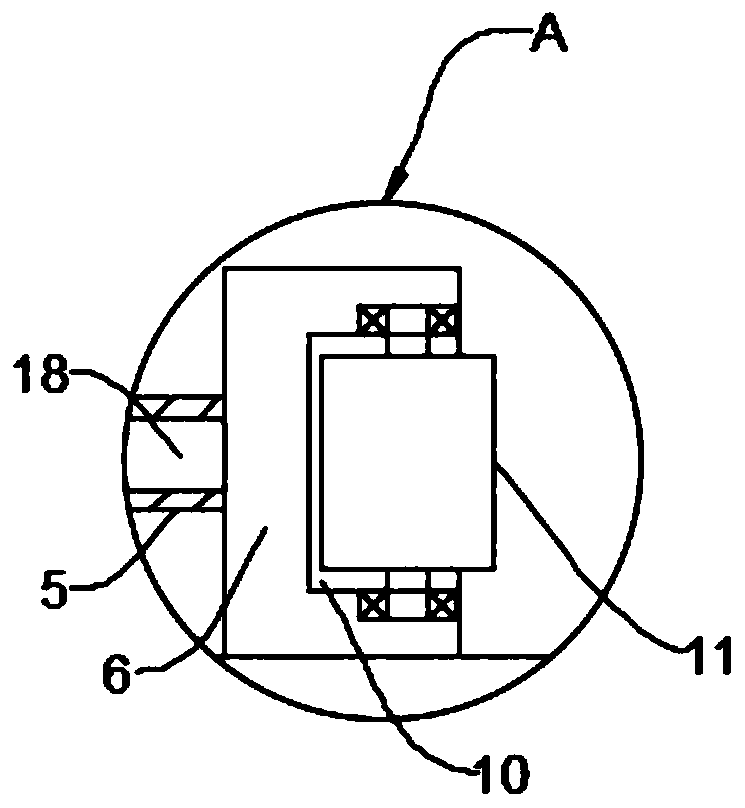

[0028] Such as Figure 1-5 As shown, a cutting device for solid wood furniture processing includes a workbench 1, a plurality of sets of vertical support feet 2 are fixedly connected to the bottom end of the workbench 1, and a cutting assembly 3 is arranged on the table of the workbench 1, and one side of the cutting assembly 3 There is a fixed bar 4 fixedly connected with the workbench 1 and the axis is parallel to the cutting direction. The threaded rod 5 perpendicular to the cutting direction is threaded on the fixed bar 4. The end of the threaded rod 5 close to the cutting assembly 3 is rotatably connected with a guide 6 The other side of the cutting assembly 3 is provided with a moving block 7 slidingly connected with the workbench 1 along the cutting direction. The side of the moving block 7 close to the cutting assembly 3 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com