Efficient demolding injection mold

An injection mold and demolding technology, applied in the field of mold manufacturing, can solve the problems affecting the overall work efficiency, product inclination, and difficulty of the injection molding process, and achieve the effects of avoiding repeated bonding, improving smoothness, and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

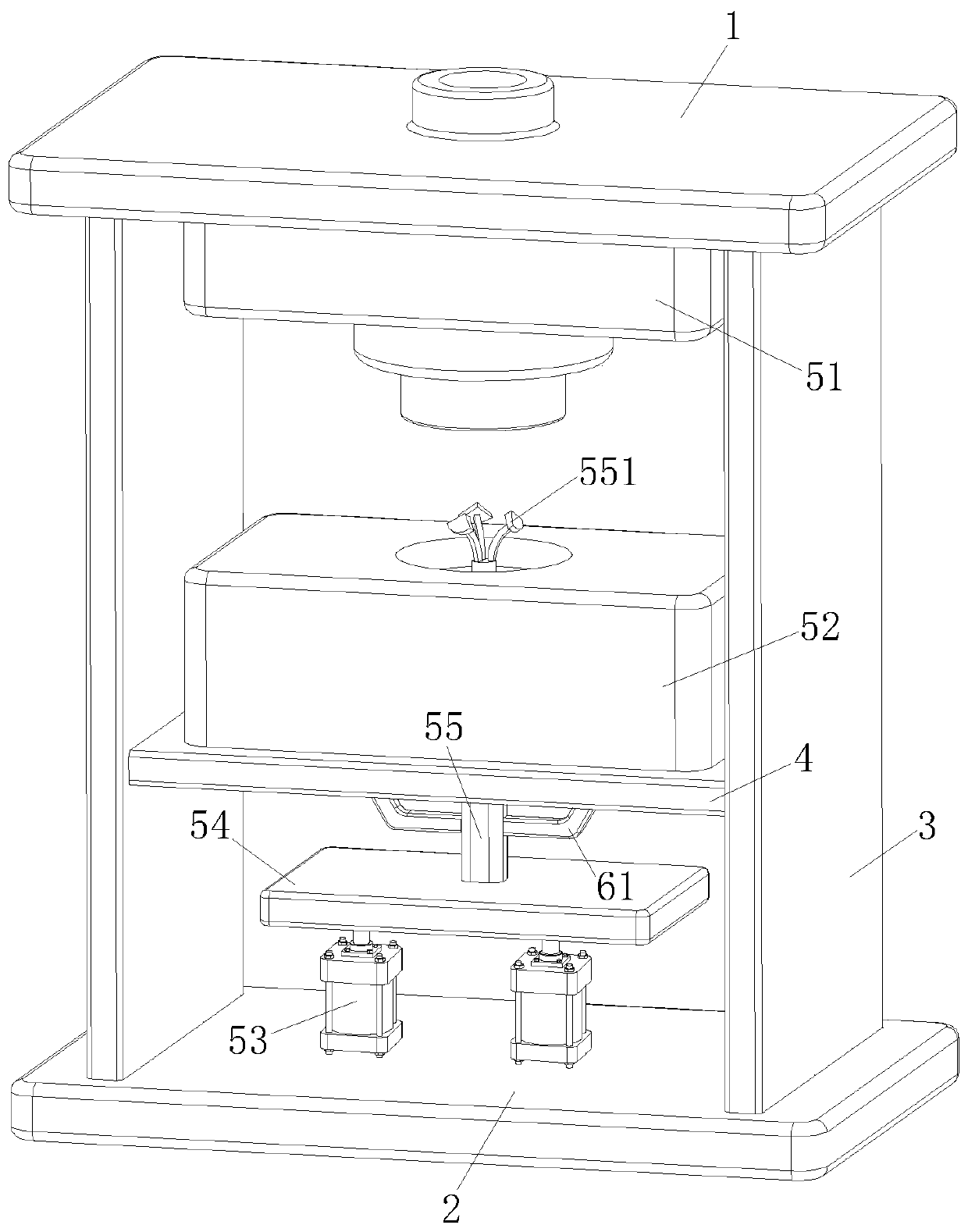

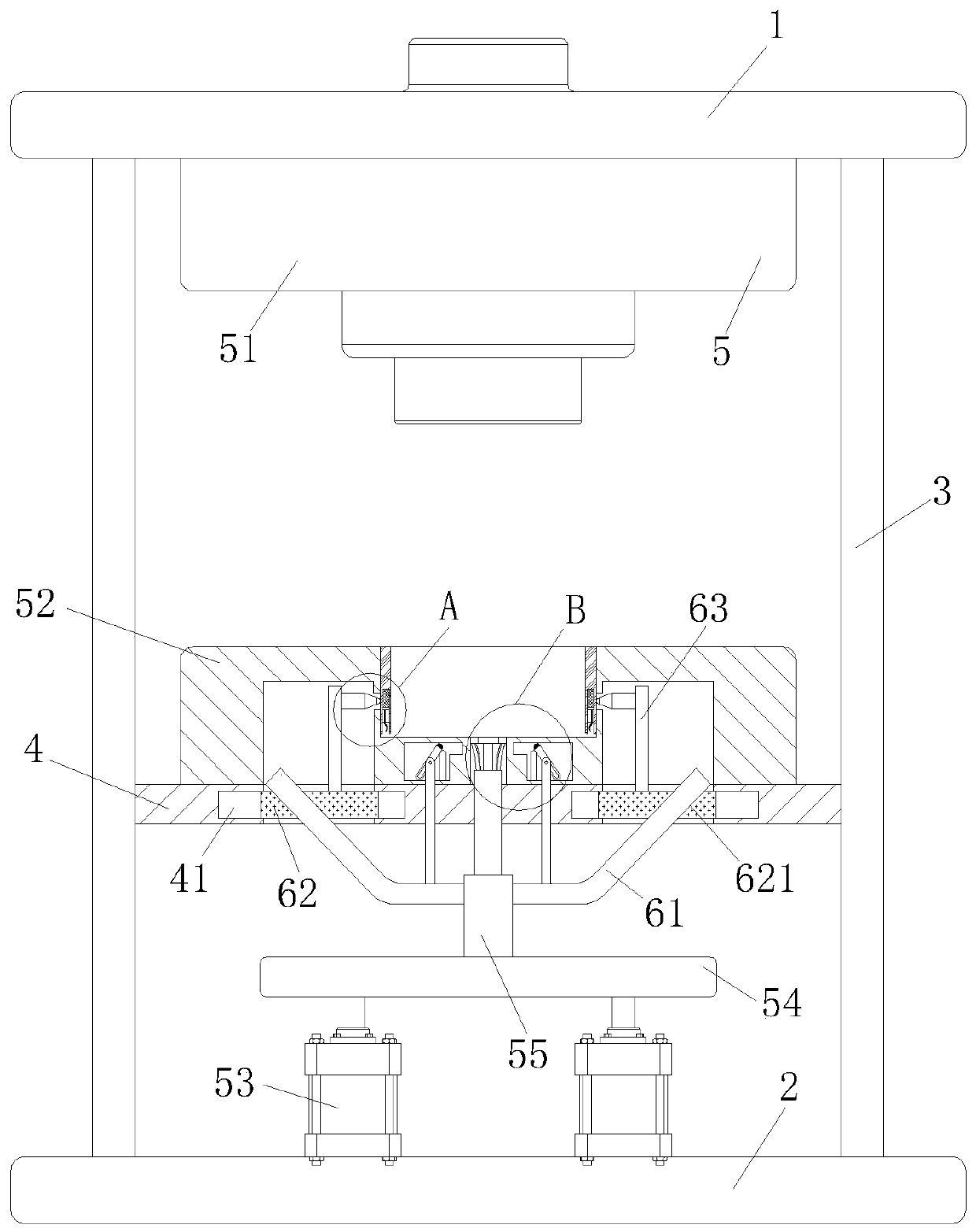

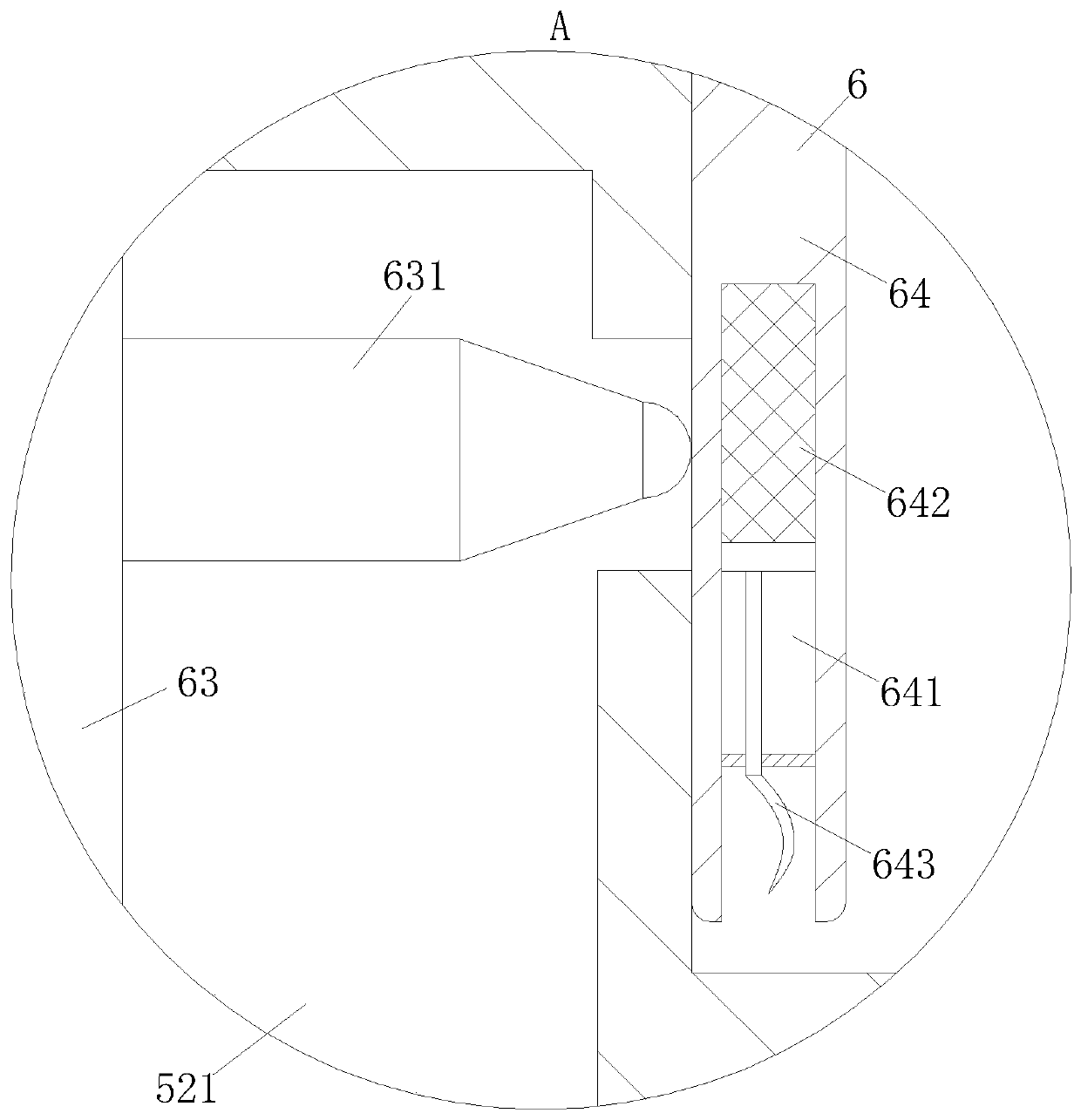

[0022] As an embodiment of the present invention, a No. 1 cavity 521 is opened in the lower mold 52; a No. chute 41 is opened in the backing plate 4 close to the No. 1 cavity 521; A jacking unit 6 is provided; the jacking unit 6 includes a folding rod 61, a slider 62, a push rod 63 and a shrapnel 64; the slider 62 is slidably connected in the No. 1 chute 41, and the slider 62 is opened There is a slanted hole 621; the folding rod 61 is installed on the side wall of the ejector rod 55, and the end of the folding rod 61 is slidably connected in the slanted hole 621; the push rod 63 is slidably connected in the first cavity 521 , and the bottom end of the push rod 63 is installed on the top side wall of the slider 62, and the push rod 63 is provided with a top block 631 on the side wall close to the ejector rod 55; the elastic piece 64 is installed on the inner side wall of the lower die 52, and the elastic piece 64 is in contact with the side wall of the top block 631; through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com