High-strength honeycomb finished product cigarette case

A high-strength, honeycomb technology, applied in the field of cartons, can solve the problems of damaged strength, uneven anisotropy of the bending strength of the honeycomb core, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

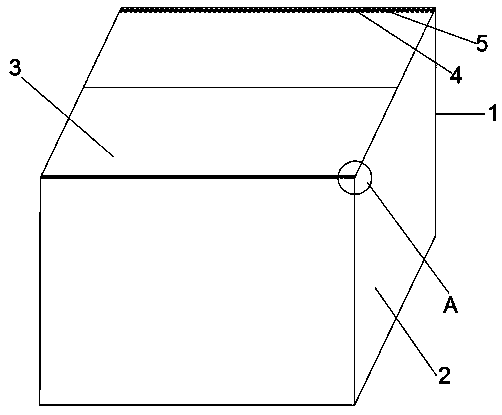

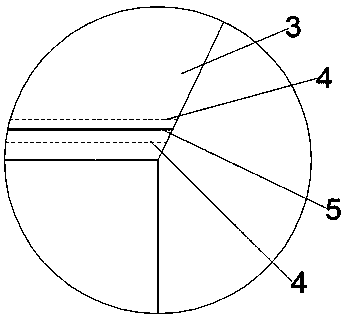

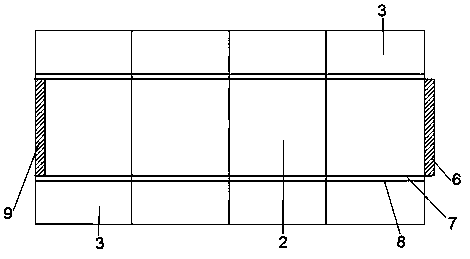

[0032] refer to Figure 1~Figure 7 : A high-strength honeycomb finished smoke box, including a box body 1, the box body 1 includes a side plate 2 and a cover plate 3 connected to the upper and lower ends of the side plate 2, the side plate 2 and the cover plate 3 form a closed space, The side panel 2 is formed by bending and splicing a piece of honeycomb paperboard 10 three times. The folded part of the cover panel 3 and the side panel 2 is provided with two inner creasing lines distributed on the inside of the box body 1 and one on the outside of the box body 1. Outer indentation 5.

[0033] In this embodiment, a connecting ear 6 is provided on one side of the side plate 2, and a connecting area 9 connected to the connecting ear 6 is reserved on the other side, so that the connecting ear 6 is connected to the connecting area 9, and the side plate 2 is surrounded. A semi-closed box body 1 with openings at the upper and lower ends is synthesized, and the cover plates 3 at the ...

Embodiment 2

[0044] refer to Figure 8~Figure 10 , compared with embodiment 1, a kind of high-strength honeycomb finished smoke box of the present embodiment has the following differences:

[0045] In this embodiment, the finished honeycomb smoke box is made of honeycomb paperboard 10 with a thickness of 12mm. The three inner indentations located at the inner side of the folded part of the box body 1 include a first inner indentation 7, a second inner indentation 8 and a third inner indentation 11; the second inner indentation 8 is close to the side plate 2, the third inner indentation The inner indentation 11 is far away from the side plate 2, the first inner indentation 7 is located in the middle of the second inner indentation 8 and the third inner indentation 11; The outer indentation 501 and the second outer indentation 502, the first outer indentation 501 and the second outer indentation 502 are respectively located in the first inner indentation 7 and the second inner indentation 8...

Embodiment 3

[0050] refer to Figure 11 and Figure 12 , compared with embodiment 1, a kind of high-strength finished smoke box of the present embodiment has the following differences:

[0051] In this embodiment, the finished honeycomb smoke box is formed by splicing two honeycomb paperboards 10 , which are defined as a first honeycomb paperboard 12 and a second honeycomb paperboard 13 .

[0052] In this embodiment, one side of the two honeycomb paperboards 10 is provided with a connecting ear 6, and the other side is provided with a connecting area 9, the two honeycomb paperboards 10 are folded once, and the upper and lower ends of the honeycomb paperboards 10 are cut Cover plates 3 are formed, and the parts between the cover plates 3 are side plates 2 . The connection ears 6 of the first honeycomb paperboard 12 and the connection area 9 of the second honeycomb paperboard 13 are glued or nailed, the connection ears 6 of the second honeycomb paperboard 13 are glued with the connection a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fold angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com