An elevator car limiting device

A limit device and elevator car technology, applied in transportation and packaging, lifting equipment in mines, elevators, etc., can solve the problems of inconvenient and flexible adjustment, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

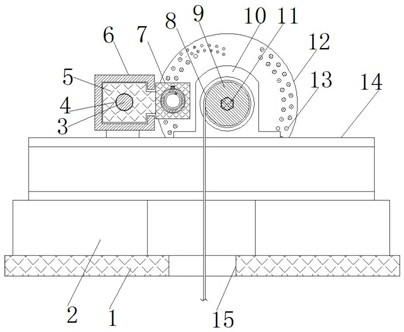

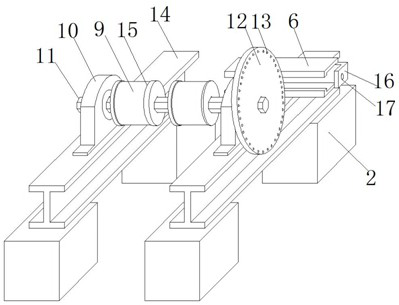

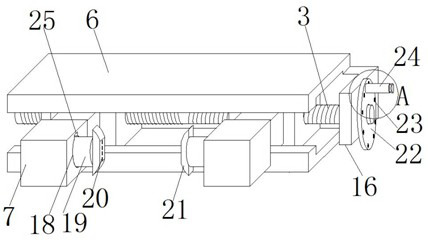

[0029] refer to Figure 1-5 , a limit device for an elevator car, comprising a base 1, a rope hole 15 is opened in the middle of the upper surface of the base 1, and a load-bearing base 2 is provided at the four corners of the upper surface of the base 1 close to the rope hole 15, and four load-bearing Two mutually parallel H-shaped steel beams 14 are fixed between the upper surfaces of the base 2, and the middle parts of the upper surfaces of the two H-shaped steel beams 14 are fixed with bearing holders 10 by bolts. The same hexagonal rod 11 is rotatably connected between them, and the outer wall of the hexagonal rod 11 is fixed with a rope reel 9. The end of the hexagonal rod 11 is sleeved with a limit plate 12, and the two sides of the limit plate 12 are close to the circumferential edge. Both are provided with equidistant staggered conical teeth 13, and the upper surface of the H-shaped steel beam 14 near the side of the limit plate 12 is fixed with a C-shaped steel slide...

Embodiment 2

[0039] refer to Figure 1-3 , a limit device for an elevator car. Compared with Embodiment 1, this embodiment also includes an annular retaining ring at both ends of the end of the two-way screw 3 close to the through hole 17 in the L-shaped clamp 16, and the annular The diameter of the retaining ring is greater than the diameter of the through hole 17 to ensure that the two-way screw 3 will not move left and right during the rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com