A kind of vacuum pipeline for high-speed train and installation assembly

A technology of vacuum pipelines and high-speed trains, applied in the directions of roads, tracks, tunnel systems, etc., can solve the problems of high-speed rails that cannot be used for the level of civil foundations, certain noise effects in lifting and lowering, and difficulty in finding a suitable position, so as to increase rigidity. And the effect of anti-side wind pressure performance, high safety and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

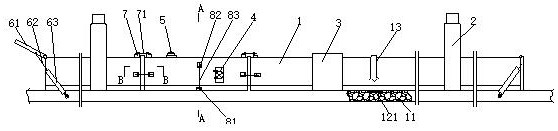

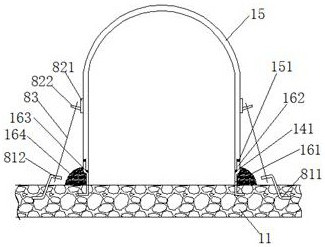

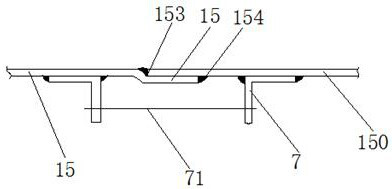

[0038] Such as Figure 1-13 Shown in, a kind of high-speed train uses vacuum pipe and installation assembly, comprises installing reinforced concrete base part 11 on the flat base body, and vacuum pipe 1 is installed on the described reinforced concrete base part 11, and the reinforced concrete base part in vacuum pipe 1 11 is provided with a track substrate 12, and the track substrate 12 is provided with a track 121; the vacuum pipeline 1 is provided with an emergency air inlet 5 controlled by a solenoid valve; the vacuum pipeline 1 is obtained by splicing segmented vacuum pipeline assemblies, The segmented vacuum pipeline assembly includes a lower pipeline prefabricated part and an upper pipeline prefabricated part 15, the lower pipeline prefabricated part is arranged symmetrically on both sides of the reinforced concrete foundation part 11, and the lower pipeline prefabricated part includes an L-shaped leg 161 at the bottom , the bottom of the L-shaped leg 161 is set in the...

Embodiment 2

[0054] On the basis of Example 1, such as Figure 14 As shown, the longitudinal section of the vacuum pipeline 1 is a part of an ellipse, and the ellipse interface has better resistance to external pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com