Highway subgrade compaction quality rapid detection method based on dynamic rebound modulus

A technology of dynamic resilience modulus and compaction quality, which is applied in the survey of on-site foundation soil, roads, roads, etc., can solve the problems of lack of direct corresponding detection and evaluation methods for design indicators, and achieve rapid detection and evaluation and efficient control, The effect of wide application range and improvement of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 takes the soil-filled subgrade as an example, and the specific test steps are as follows:

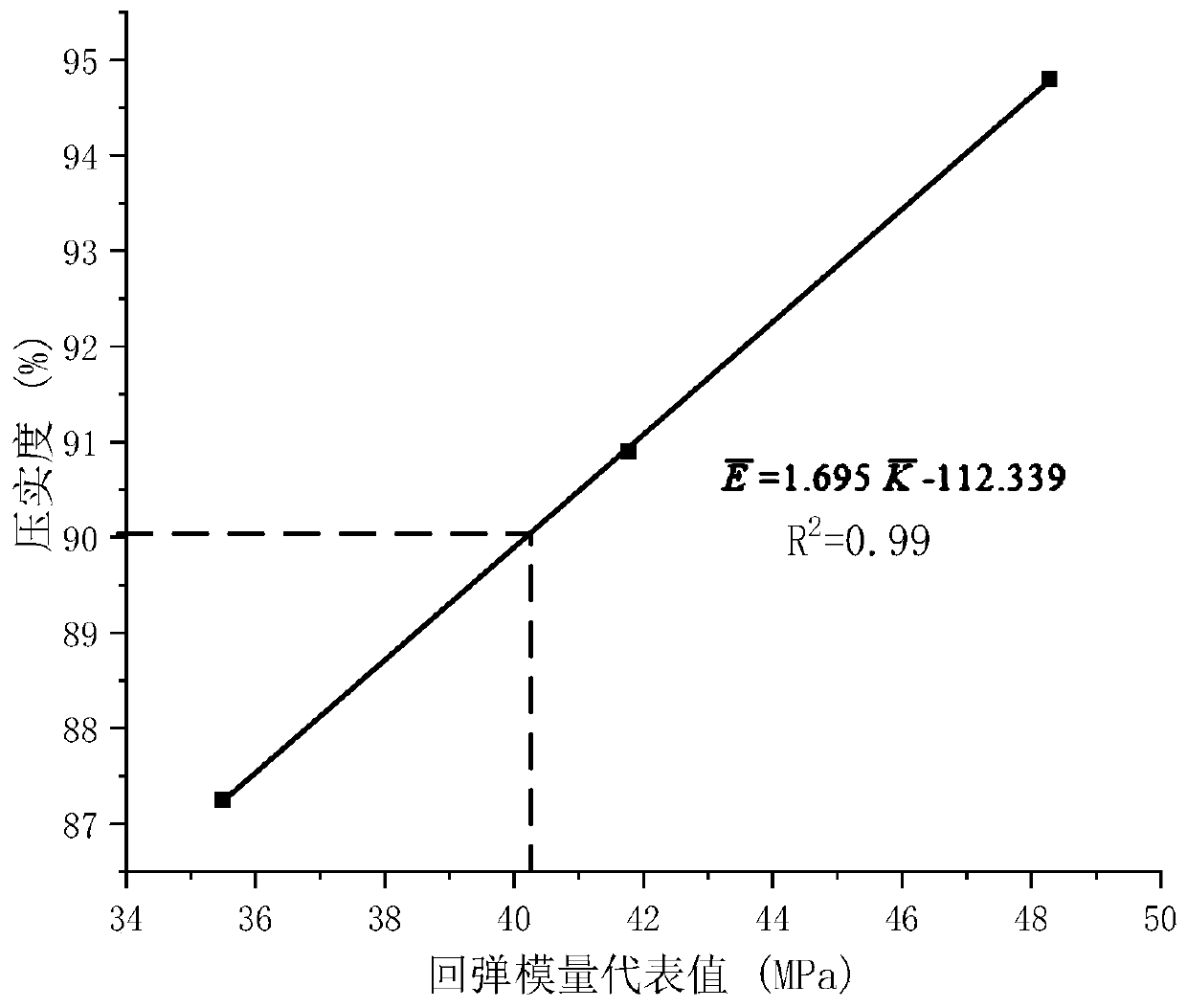

[0048] Step 1. According to the requirements of the design specifications, select the subgrade filler CBR=3%, and estimate the rebound modulus value M under the standard state R = 35.6MPa.

[0049] Step 2. Select a certain test section at the corresponding roadbed construction site as the test area, and roll it step by step;

[0050] Step 3. After each rolling is completed, randomly select a test point in the test section area, and use a portable dynamic modulus of resilience tester to measure the dynamic modulus of resilience E of this point i value, and record the data.

[0051] Step 4, then use the sand filling method to detect the degree of subgrade compaction K under the rolling times i ;

[0052] Step 5. Repeat steps 3 to 4. After each rolling, no less than 15 pieces of dynamic elastic modulus data are measured, and abnormal data are eliminated, and the dyn...

Embodiment 2

[0061] Embodiment 2 takes soil-rock mixed-fill subgrade as an example, and the specific test steps are as follows:

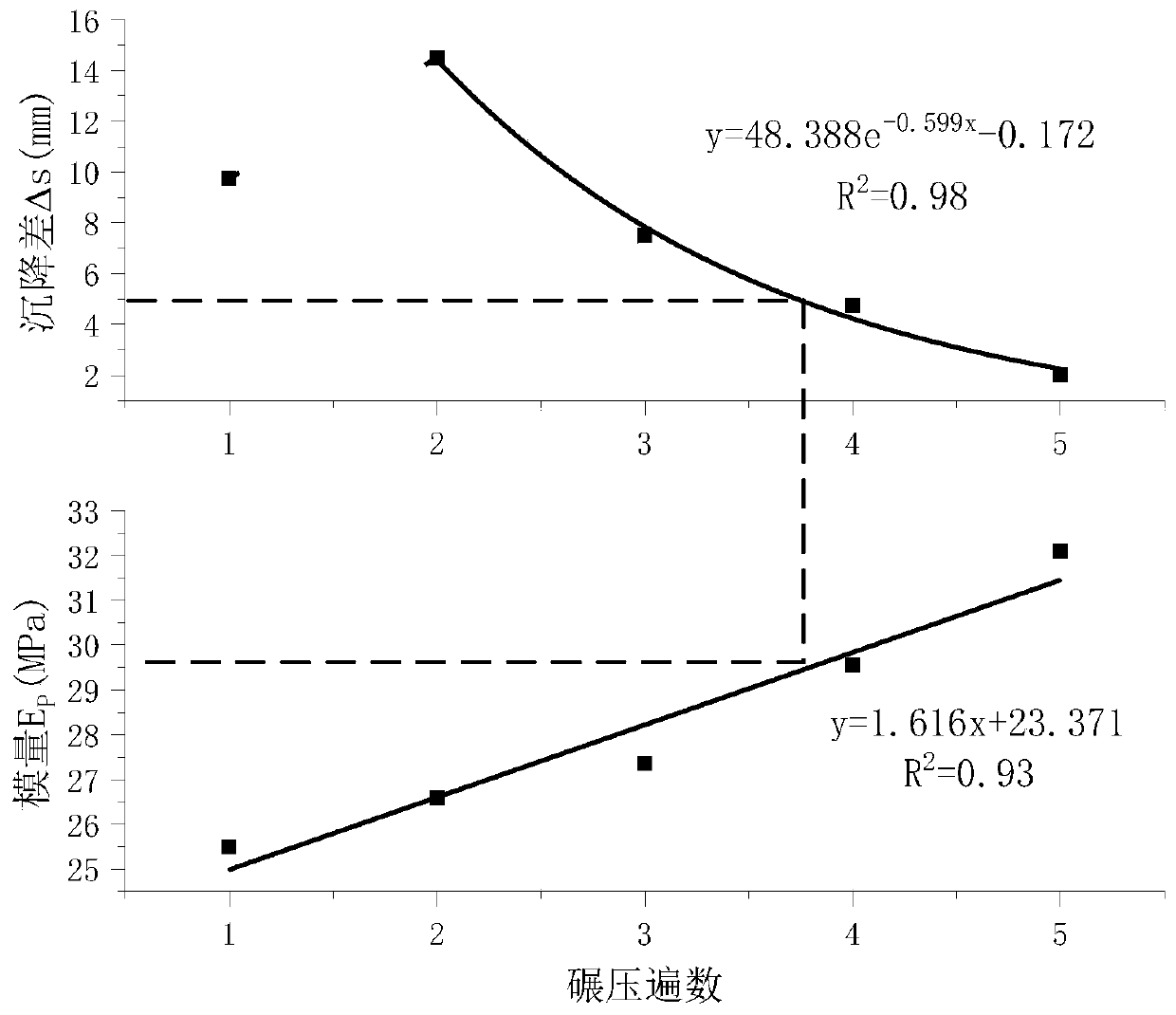

[0062] Step 1. According to the requirements of the design specifications, select the subgrade filler CBR=2%, and estimate the rebound modulus value M under the standard state R = 27.4MPa.

[0063] Step 2. Select a certain test section at the corresponding roadbed construction site as the test area, and roll it step by step;

[0064] Step 3. After each rolling is completed, randomly select a certain number of test points in the test section area, and use a portable dynamic modulus of resilience tester to measure the dynamic modulus of resilience E of the point. i value, and record the data;

[0065] Step 4, then use a high-precision level to detect the subgrade settlement value, and record the data;

[0066] Step 5. Repeat steps 3 to 4, and use the settlement difference between every 2 rollings as the construction control index. When the settlement difference...

Embodiment 3

[0071] Embodiment 3 takes the stone-filled subgrade as an example, and the specific test steps are as follows:

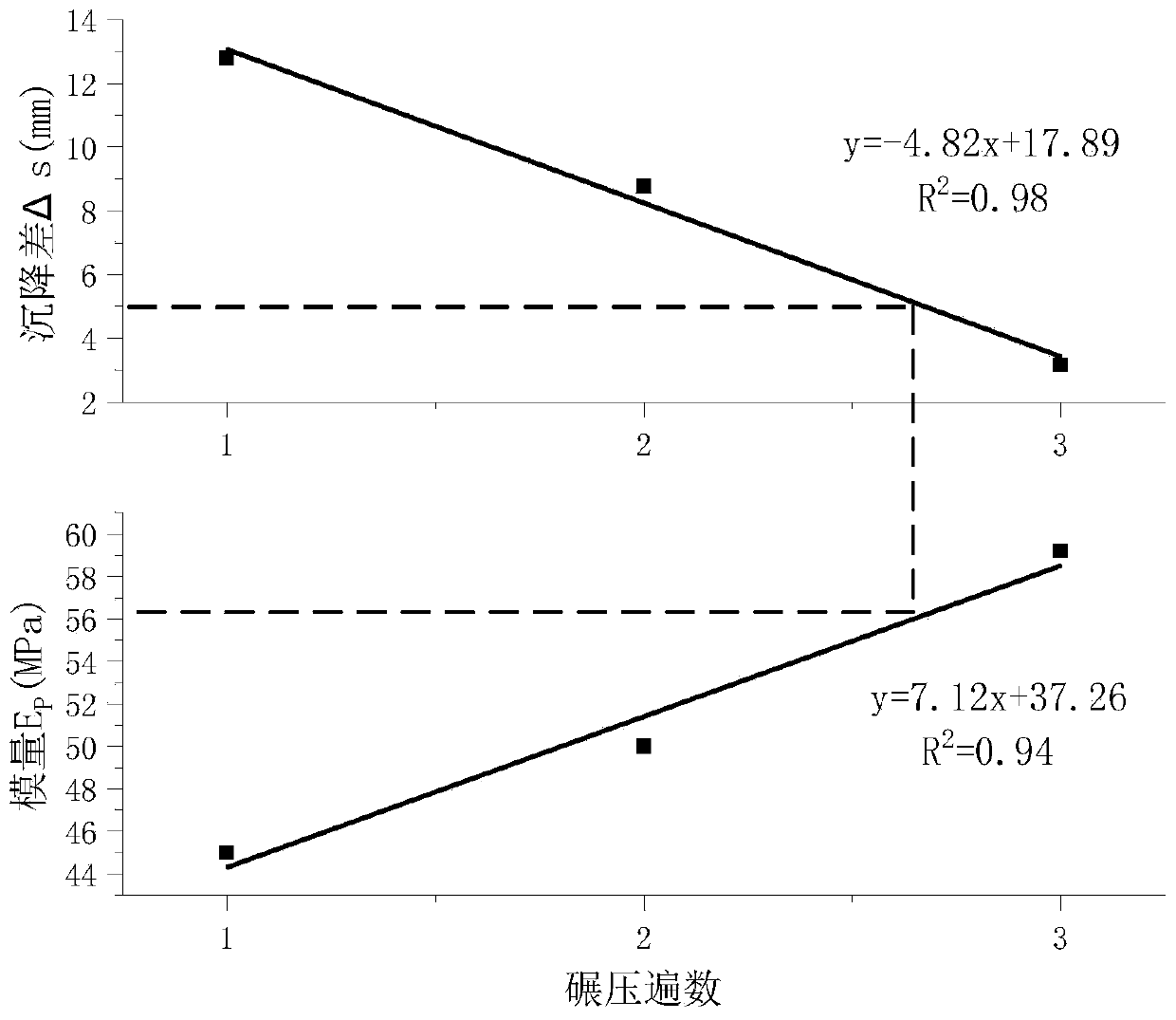

[0072] Step 1. According to the requirements of the design specifications, select the subgrade filler CBR=4%, and estimate the rebound modulus value M under the standard state R = 42.7MPa.

[0073] Step 2. Select a certain test section at the corresponding roadbed construction site as the test area, and roll it step by step;

[0074] Step 3. After each rolling is completed, randomly select a certain number of test points in the test section area, and use a portable dynamic modulus of resilience tester to measure the dynamic modulus of resilience E of the point. i value, and record the data;

[0075] Step 4, then use a high-precision level to detect the subgrade settlement value, and record the data;

[0076] Step 5. Repeat steps 3 to 4, and use the settlement difference between every 2 rollings as the construction control index. When the settlement difference Δ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com