Underground diaphragm wall foundation pit construction method

An underground continuous wall and construction method technology, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of the need to improve the construction efficiency, affect the construction progress, and prolong the construction period, so as to improve the convenience and stability, Improve the use effect and strengthen the effect of connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

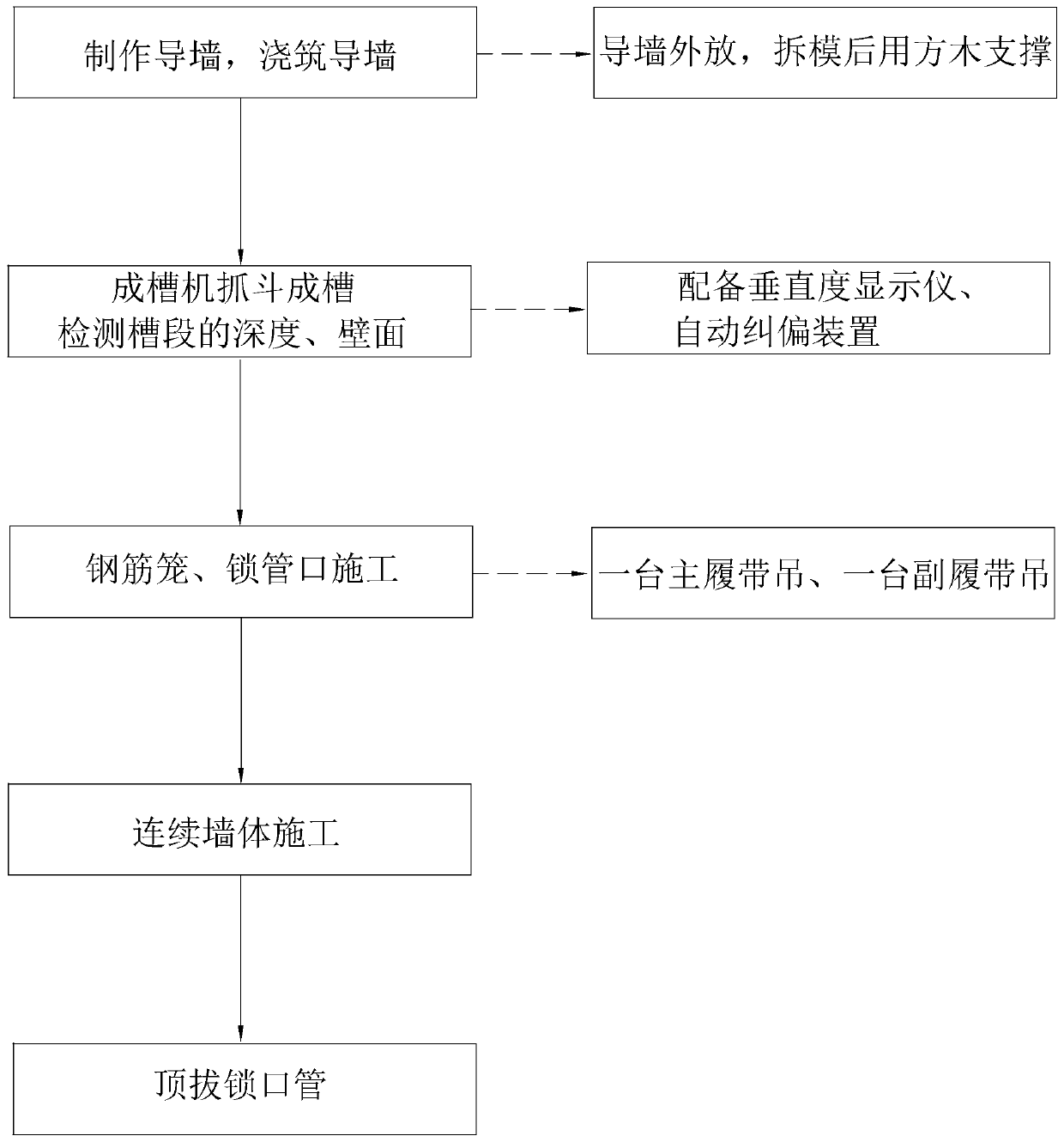

[0030] Such as figure 1 Shown, a kind of underground diaphragm wall foundation pit construction method comprises the following steps:

[0031] Before the underground diaphragm wall is grooved, the guide wall should be made first, and the total station should be used for lofting. Considering the construction error and the convergence of the maintenance structure during the excavation of the foundation pit, the guide wall needs to be properly placed outside. In this embodiment, it is preferable to place 8CM outside. ; The guide wall adopts an integral reinforced concrete structure, and the steel bars are bound, and the formwork is reinforced. At the knuckles of the ground wall, in order to ensure the quality of the groove, the knuckles need to be lengthened by a certain length. This embodiment preferably lengthens 30CM, and made "Ten" shape; after the strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com