Positioning structure for stiffening steel plate shear wallboard and installation method of positioning structure

A steel plate shear wall and steel plate shear force technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of a large number of operators, low positioning accuracy, large cumulative deviation, etc., to achieve a simple structure principle, easy to observe , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

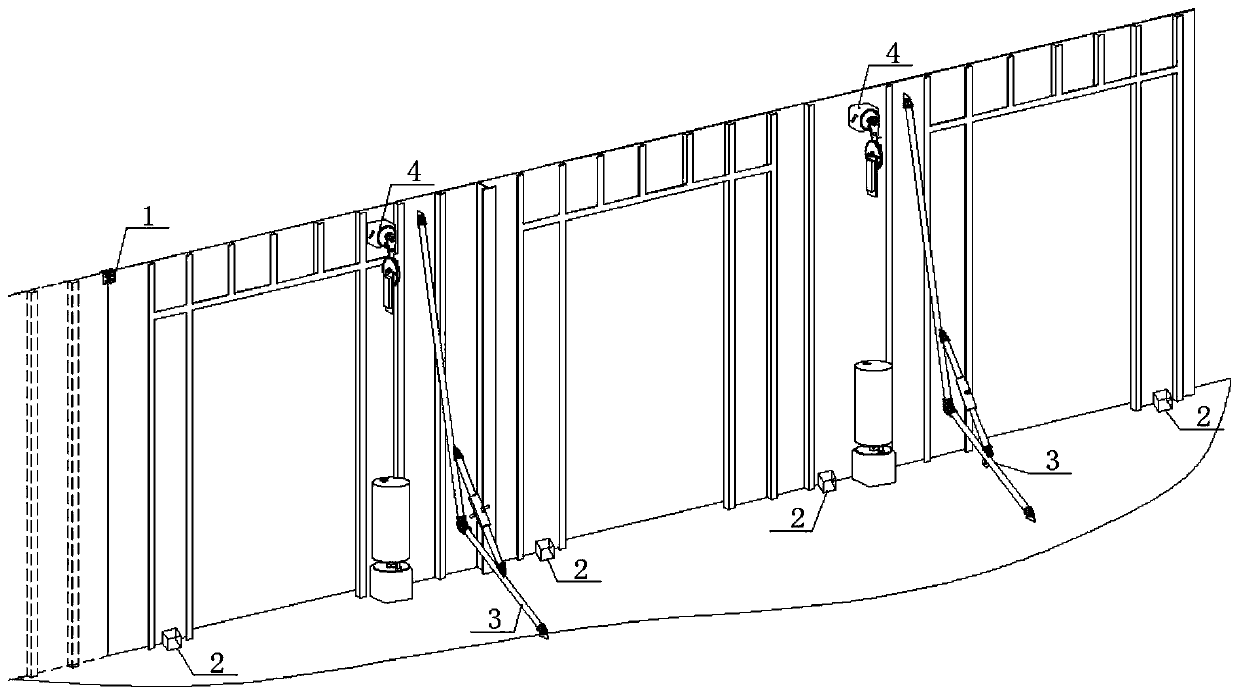

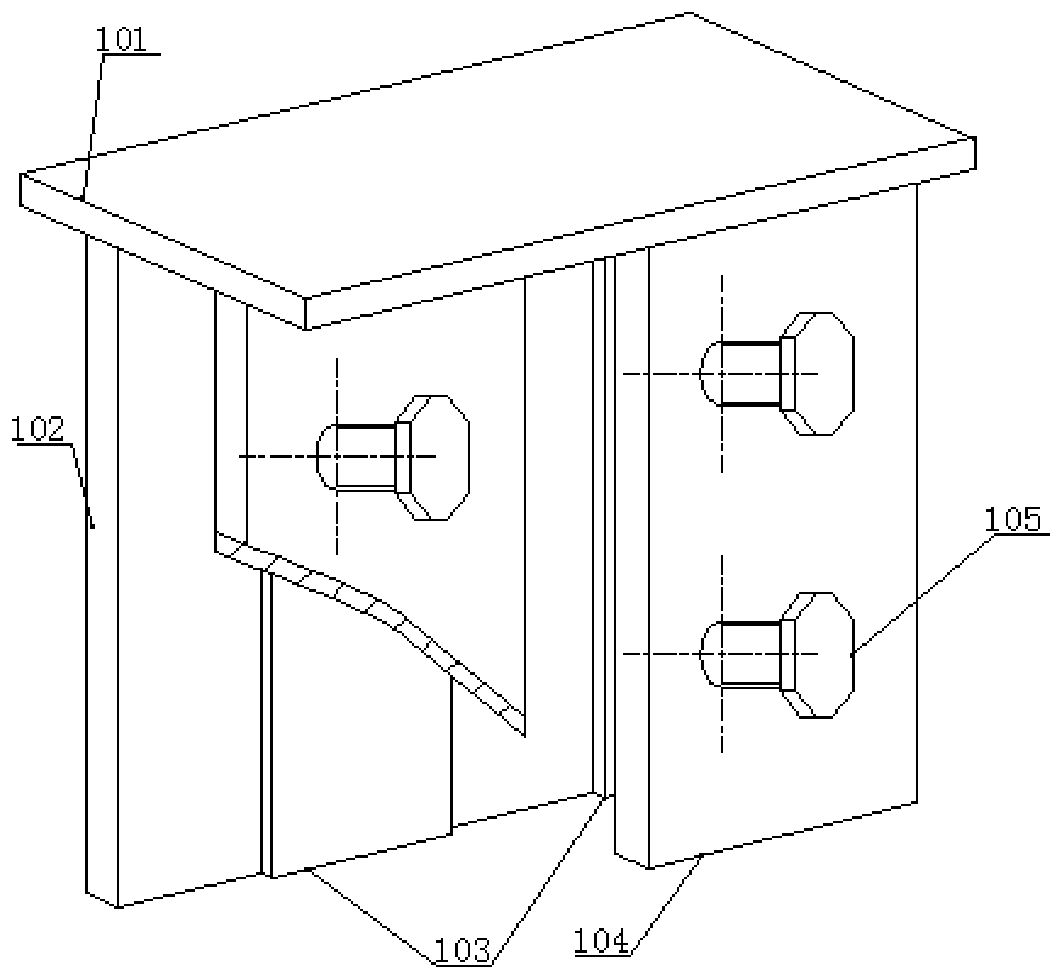

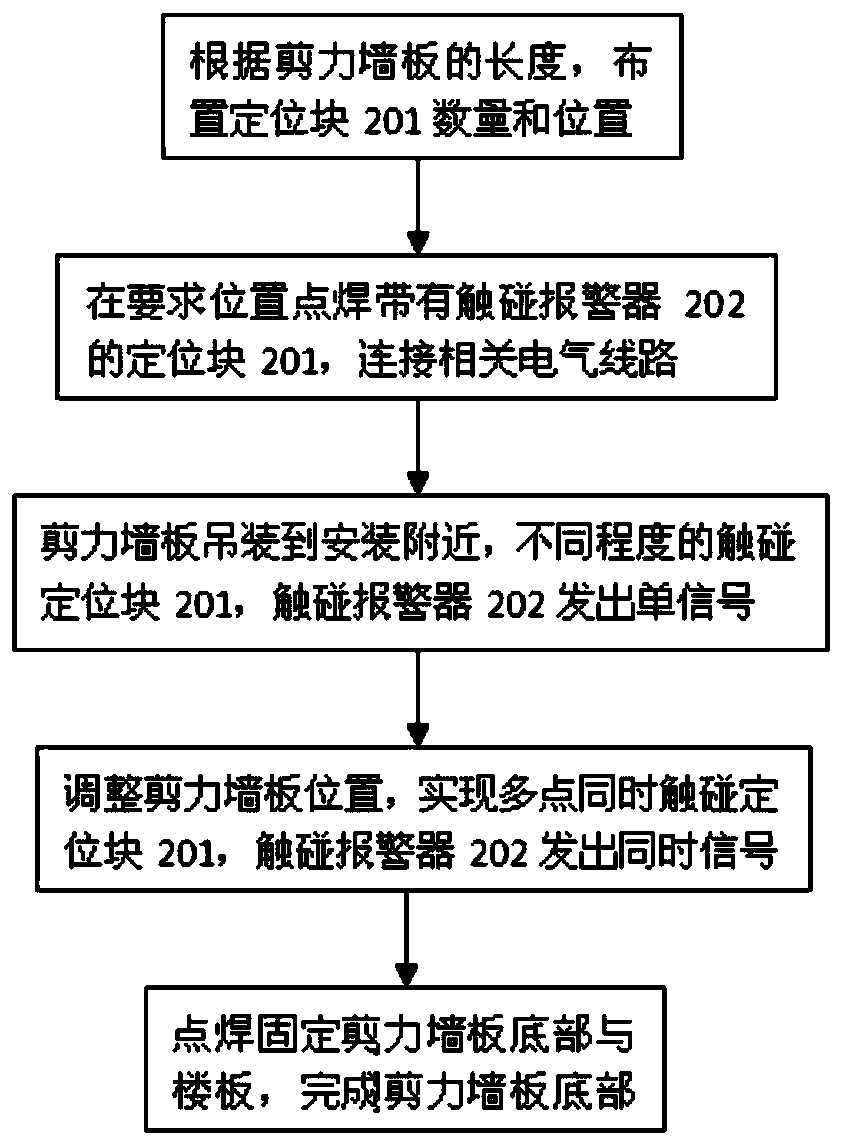

[0088] Such as figure 1 , 2 As shown, a method for positioning and installing a stiffened steel plate shear wall panel in a prefabricated box-plate steel structure building includes a positioning alarm device, an adjustable support device, a vertical detection device, and a shear wall panel clamping device. The specific steps are as follows:

[0089] Step 1, select appropriate parts according to the site conditions, and complete the assembly and positioning of the positioning alarm device 2, the assembly of the adjustable support device 3, the laser line projection device 401 and the prism reflection device 402.

[0090] Step 2: Hoist the shear wall panel to the installation place by hoisting equipment. When the shear wall panel touches the touch sensor 204 at a single point, a single alarm is issued, and the position of the shear wall panel is adjusted to realize simultaneous alarm at each positioning point. Spot welding shears The bottom of the force wall plate is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com