Composite gas sensor detection device

A composite gas and detection device technology, applied in the field of sensors, can solve the problems of shortening the test time of the sensor T90, large volume of all-in-one gas chamber, cumbersome assembly, etc., and achieve the effects of shortening the test time, solving the lengthy gas path and various combination methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the concrete structure of the present invention is as follows:

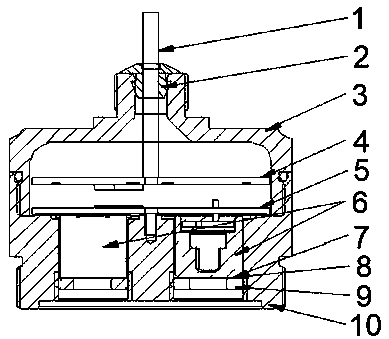

[0034] Please refer to the attached Figure 1-3 , a sensor detection device for composite gas of the present invention, comprising:

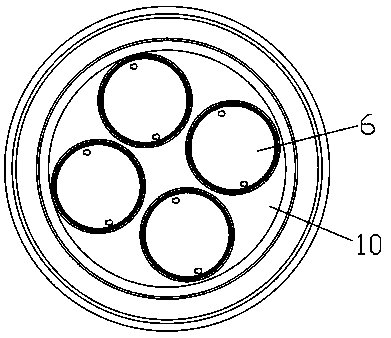

[0035] A gas chamber main body 10 is provided with a plurality of independent sensor group installation cavities so that each sensor group is isolated from each other, and the inlet ends of each sensor group installation cavity communicate with a common air cavity so that each sensor 6 can detect gas ;

[0036] The air chamber connector 3 detachably installed on the upper end of the air chamber main body 10, the connection between the air chamber connector 3 and the air chamber main body 10 is provided with a sealing ring to form a sealing structure and in the air chamber A cavity is provided in the chamber connector 3 to accommodate two PCB boards, and a connection portion is provided at the lower end of the air chamber main body 10;

[0037] The sensor gro...

Embodiment 2

[0050] like figure 1 , 3 as shown, figure 1 It is a structural diagram of a sensor detection device with a diffusion structure in Embodiment 2 of the present invention.

[0051] Overview of Diffusion Structure Composition: Based on image 3 Take the four-in-one air chamber body diffusion type as an example, the sensor 6 is inserted on the pin PCB board, and the pin PCB board is locked on the air chamber main body 10 with a single-headed copper column, and is connected with the signal processing PCB board pin row female, and the signal processing The PCB board is locked on the single-head copper post, the air chamber main body 10 is screwed and fixed with the air chamber joint 3, the sensor 6 is protected by the gasket 7 and the waterproof and dustproof assembly 8, and the gasket 7 and the waterproof and dustproof combination 8 are pressed by the pressure ring 9 The threaded connection with the air chamber main body 10 is fixed.

[0052] The use form and working principle o...

Embodiment 3

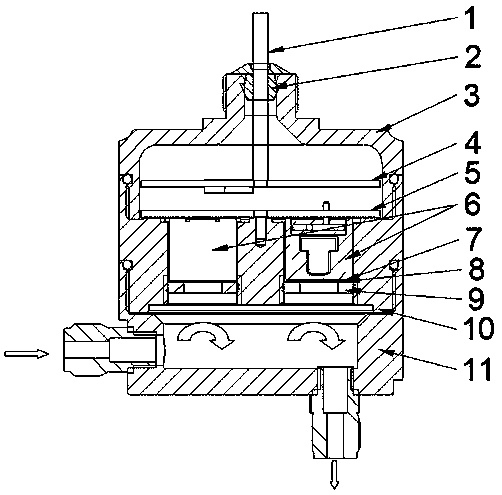

[0054] like Figure 2-3 as shown, figure 2 It is a structural diagram of a flow-through sensor detection device in Embodiment 3 of the present invention.

[0055] Overview of the composition of the flow-through structure: Taking the flow-through type of the main body of the four-in-one air chamber in Figure as an example, a flow-through joint 11 is added on the basis of the diffused structure;

[0056] The use form and working principle of the flow-through structure: the air chamber main body 10 is fixed by the thread on the air chamber joint 3; the air chamber main body 10 is sealed as a whole, and the wiring harness 1 passes through the sealing sleeve 2 and is sealed with the air chamber joint 3 with potting glue, and the air chamber The joint 3 is sealed with the sealing ring of the gas chamber main body 10 , the flow-through joint 11 is sealed with the sealing ring of the gas chamber main body 10 , and the sensor 6 is sealed with a gasket 7 . The gas to be detected flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com