Fault early warning sensor for high-voltage cable connector

A fault warning and high-voltage cable technology, applied in the field of high-voltage electricity, can solve problems such as partial discharge, degradation, and cable breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

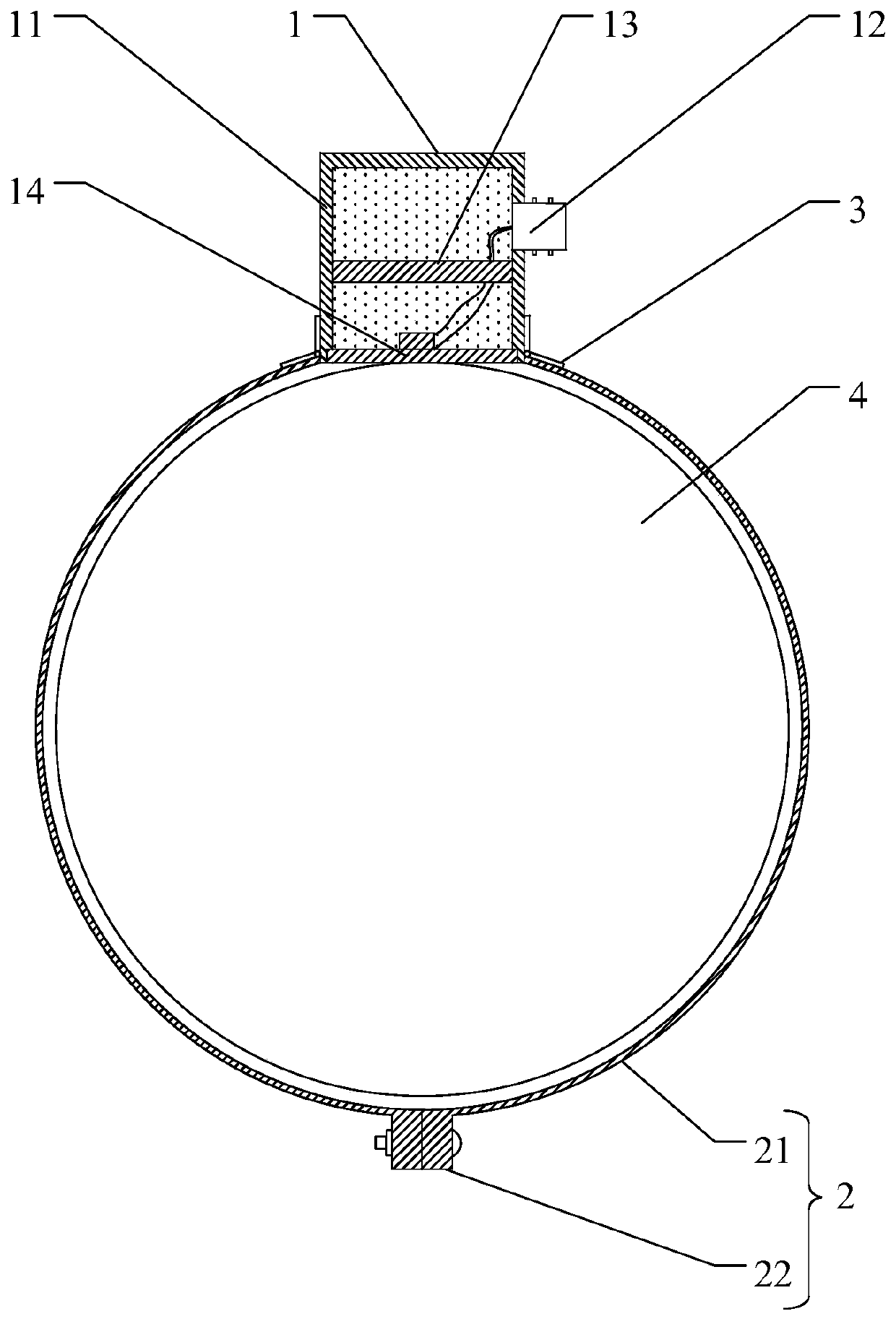

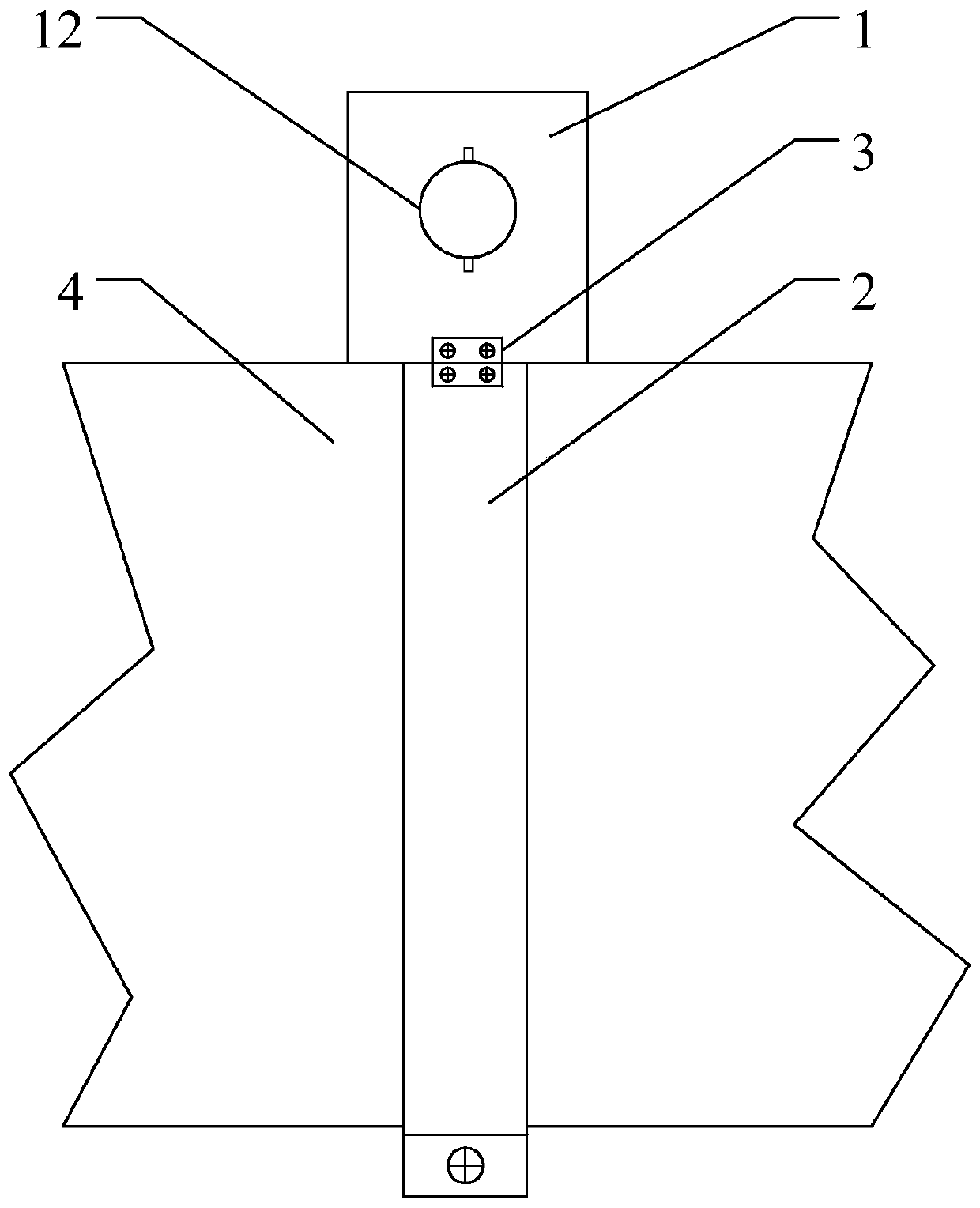

[0015] figure 1 It is a high-voltage cable joint fault early warning sensor of the present invention, including a sensor 1 and a hoop 2. The hoop 2 is composed of two arc-shaped hoops 21, and the two sides of the sensor 1 and the two arc-shaped hoops 21 pass through the hinge 3. hinged.

[0016] The sensor 1 includes a housing 11 , a communication interface 12 , a circuit board 13 and a probe 14 . The communication interface 12 is arranged on the casing 11, the circuit board 13 is defined inside the casing 11, the communication interface 12 and the probe 14 are connected to the circuit board 13 through wires, the probe 14 is fixed under the casing 11, and the surface of the probe 14 and the cable connector 4 touch. The probe 14 can detect the abnormal signal of the cable joint 4 and transmit it to the circuit board 13 , the circuit board 13 transmits the signal to the communication interface 12 after processing, and the communication interface 12 transmits the signal detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com