Control method and system of electro-hydrostatic actuator

An electro-hydrostatic actuation and control method technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as differential explosion control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

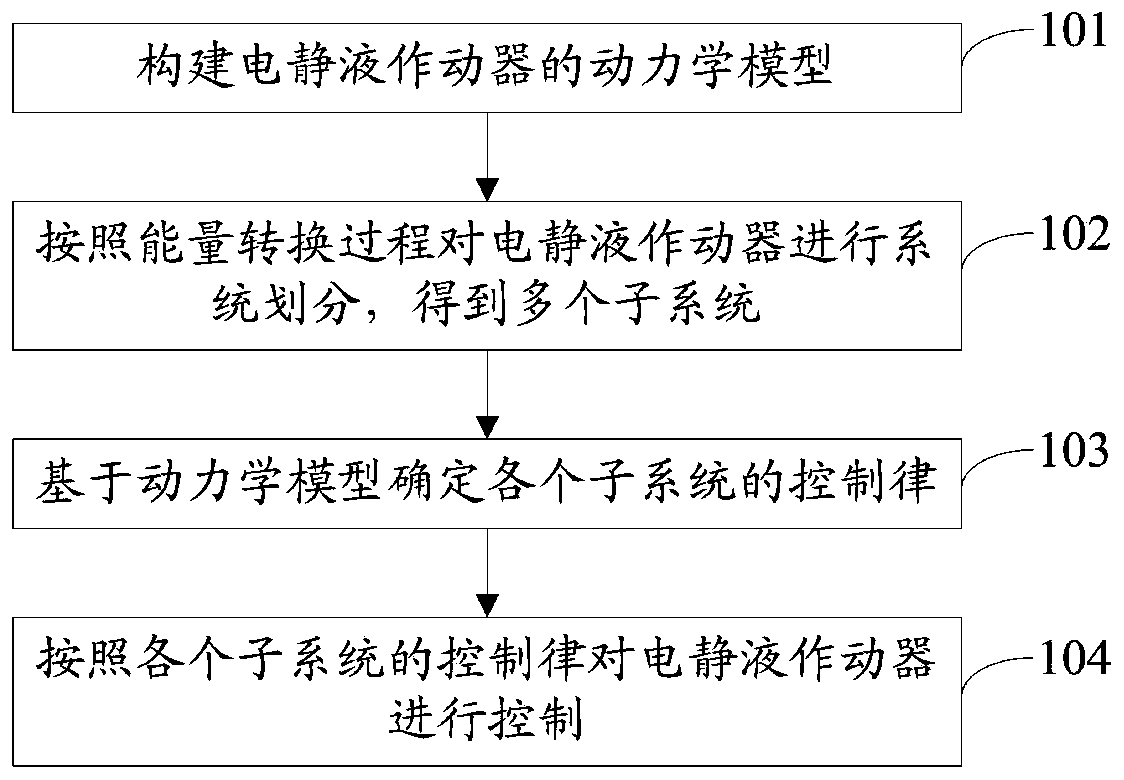

[0119] figure 1 It is a method flowchart of the control method of the electrostatic fluid actuator according to Embodiment 1 of the present invention.

[0120] see figure 1 , the control method of the electrostatic fluid actuator, comprising:

[0121] Step 101: Construct a dynamic model of the electrohydrostatic actuator.

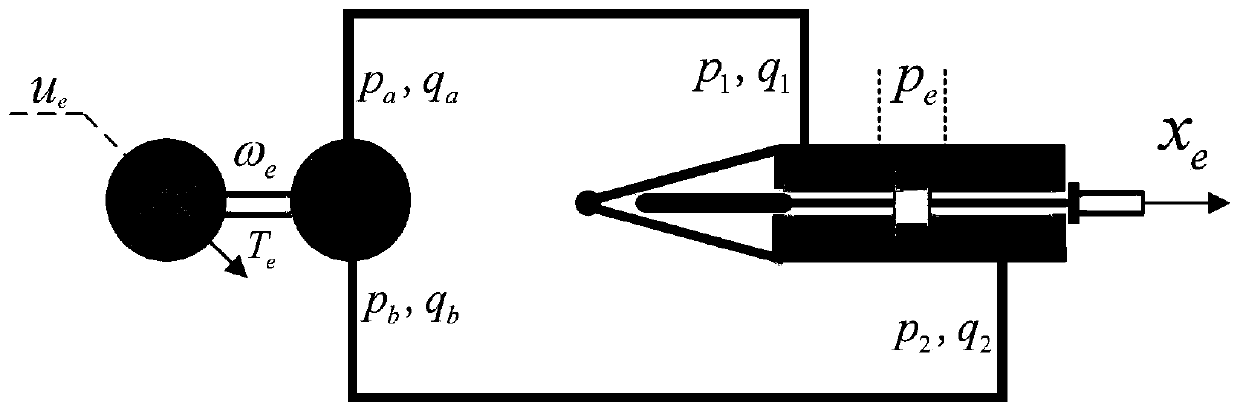

[0122] The electrohydrostatic actuator includes a motor, a pump, and an actuator; the motor is used to drive the pump to change the pressure of the hydraulic cylinder, which in turn drives the actuator.

[0123] Step 101 specifically includes:

[0124] Using the brushless DC motor as the motor of the electrohydrostatic actuator, the potential balance equation of the motor is established:

[0125]

[0126] where u e is the motor control voltage; i e is the motor current; K e is the back electromotive force coefficient of the motor; ω e is the motor speed; R e is the motor armature resistance; L e is the motor armature inductance, for i e The ...

Embodiment 2

[0170] This embodiment 2 is a more specific embodiment relative to embodiment 1.

[0171] Basic theory:

[0172] L 2 and L ∞ Stability Theoretical Basis:

[0173] Lebesgue space (Lebesgue space) has the following definition:

[0174] Definition 1: Lebesguespace, with L p Represents and p is a positive integer, its measurable and integrable function f(t) satisfies:

[0175]

[0176] Consider two special cases:

[0177] (a) A Lebesgue measurable function f(t) belongs to L 2 if and only if

[0178] (b) A Lebesgue measurable function f(t) belongs to L ∞ if and only if

[0179] L 2 is a second-order Lebesgue space, L ∞ is a Lebesgue space of infinite order.

[0180] The following three lemmas can prove that L 2 and L ∞ stability

[0181] Lemma 1: Consider a nonnegative differentiable function ξ(t) defined as

[0182]

[0183] Among them, a i >0 and n≥1. If the differential of ξ(t) with respect to time is Lebesgue integrable and

[0184]

[0185] Amon...

Embodiment 3

[0377] This embodiment 3 discloses a control system of an electrostatic fluid actuator, including:

[0378] A dynamic model building block for constructing a dynamic model of an electrohydrostatic actuator;

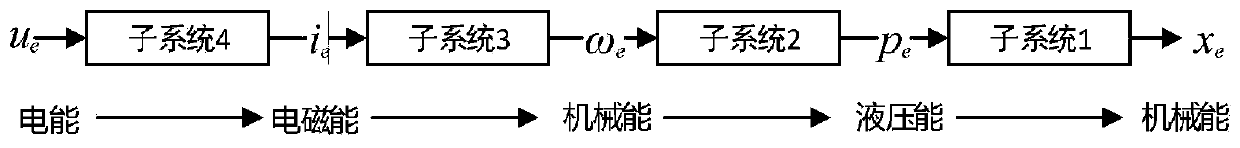

[0379] A system division module is used for system division of the electrostatic fluid actuator according to the energy conversion process to obtain multiple subsystems;

[0380] A control law determination module, used to determine the control laws of each subsystem based on the dynamic model;

[0381] The control module is used for controlling the electrostatic fluid actuator according to the control law of each subsystem.

[0382] Optionally, the electrohydrostatic actuator includes a motor, a pump, and an actuator; the motor is used to drive the pump to change the pressure of the hydraulic cylinder, and then drive the actuator;

[0383] Kinetic model building blocks include:

[0384] The potential balance equation establishment unit is used to establish the potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com