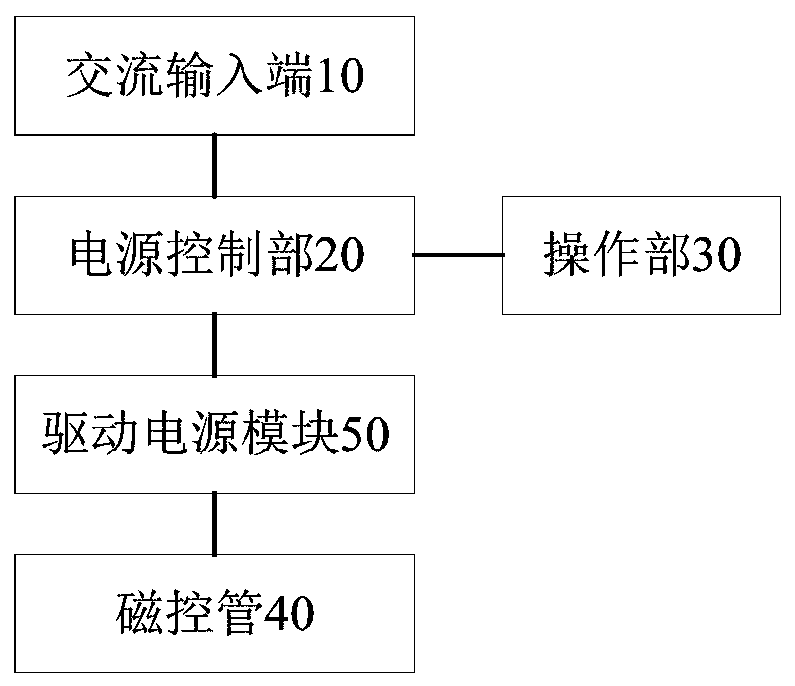

Magnetron control system, magnetron control method and high-frequency heating device

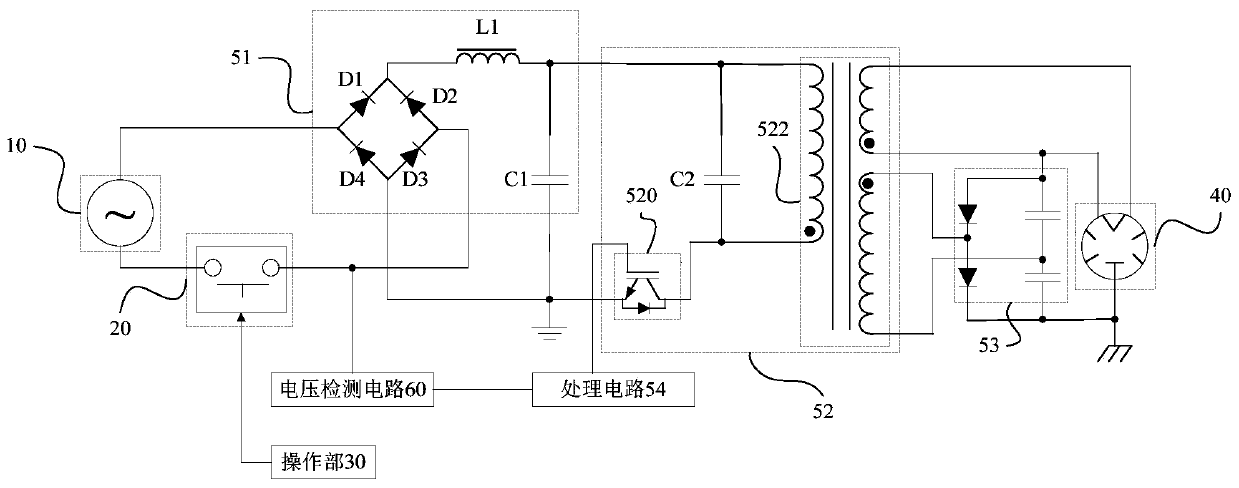

A control system and magnetron technology, applied in control/regulation systems, magnetrons, output power conversion devices, etc., can solve the problems of magnetron drive power module wiring and cost increase, and reduce the number of connections. To, reduce wiring and components, realize the effect of variable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] When the status information of the power control unit 20 includes the switching times of the power control unit 20, it can be understood that when the control command received by the operation unit 30 continues to be at a high level, that is, the time for which the power control unit 20 is continuously turned on is longer than the preset time At T1, the processing circuit 54 calculates the high level, that is, the number of times the control instruction received by the operation unit 30 has changed from a high level to a low level before the power control unit 20 has been turned on longer than the preset time T1, that is, the power control unit 20 switching times, when the control command received by the operation unit 30 before the high level starts to change from high level to low level, that is, when the switching times of the power supply control unit 20 is 0, the processing circuit 54 will switch The on-off time ratio of the device 520 is controlled so that the volt...

Embodiment 2

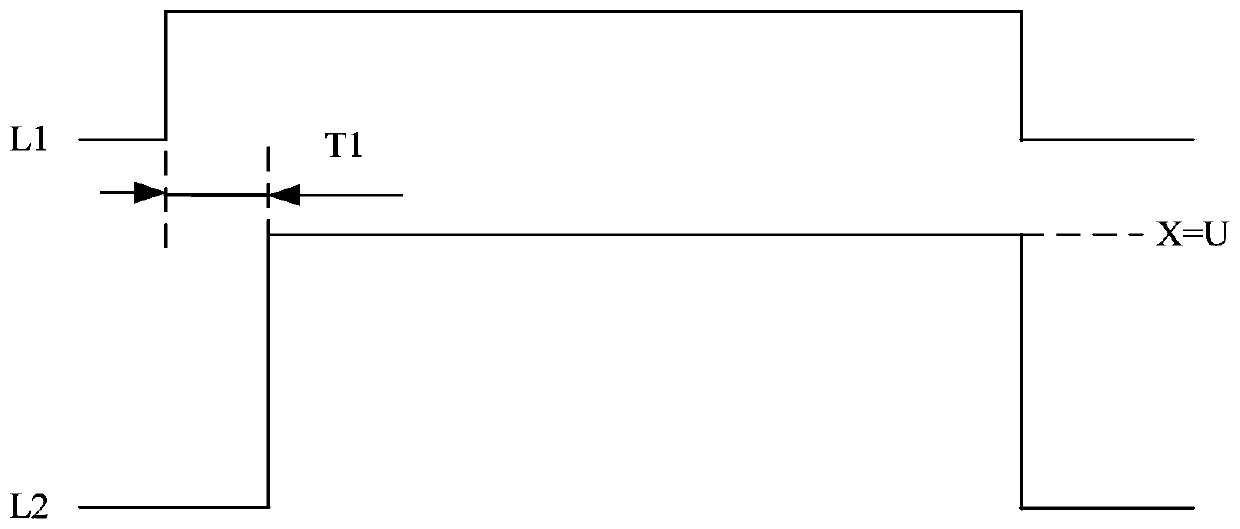

[0061] When the status information of the power control unit 20 includes the turn-on time of the power control unit 20, it can be understood that, as Figure 9 As shown, wherein, L1 represents the waveform diagram of the control command received by the operation unit 30, L2 represents the waveform diagram of the voltage applied to the magnetron 40 by the drive power supply module 50, and the voltage applied to the magnetron 40 by the drive power supply module 50 In the case of the maximum voltage U, the processing circuit 54 calculates the time T2 during which the control command received by the operation unit 30 is continuously at a high level, that is, the power control unit 20 is continuously turned on. If the time value is equal to the first preset value A, that is, T2 =A, then the processing circuit 54 controls the on-off time ratio of the switching device 520, so that the voltage X applied to the magnetron 40 by the drive power supply module 50 is set to 50% U, that is, X...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap