Correction mechanism and correction method on silicon wafer etching equipment

A technology for etching equipment and silicon wafers, which is applied in the manufacture of conveyor objects, electrical components, semiconductors/solid-state devices, etc., can solve the problems that the front and rear positions of silicon wafers cannot be corrected, and achieve the effect of reducing wear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

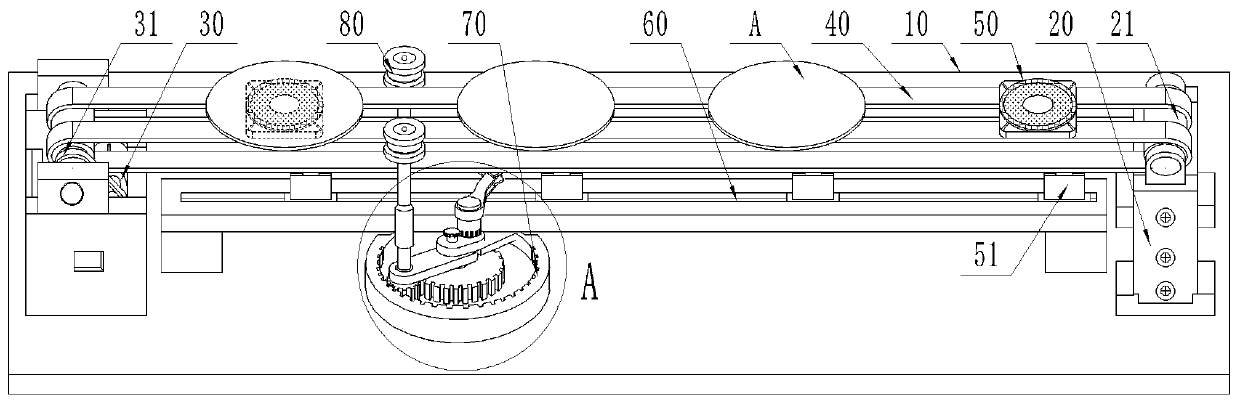

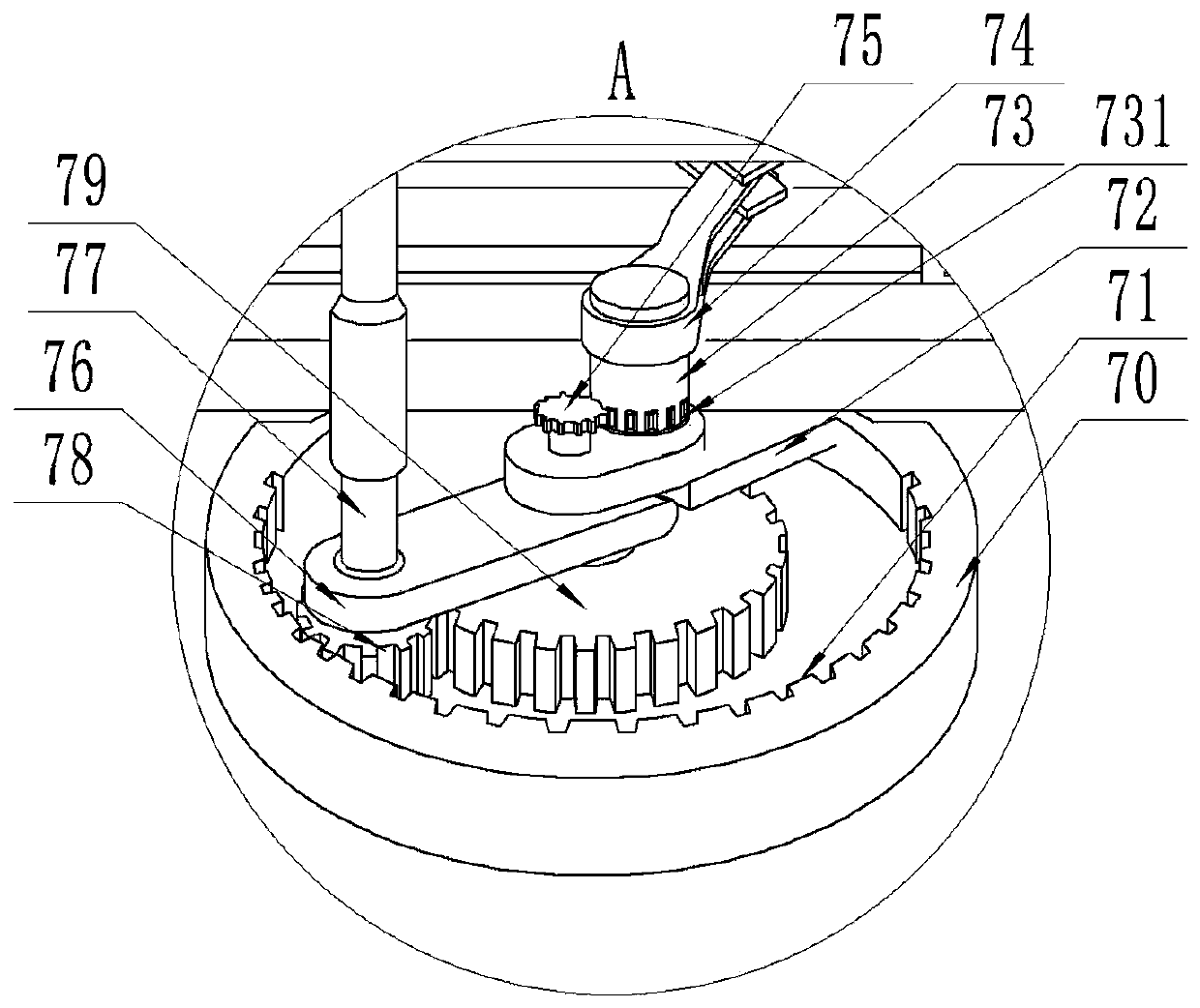

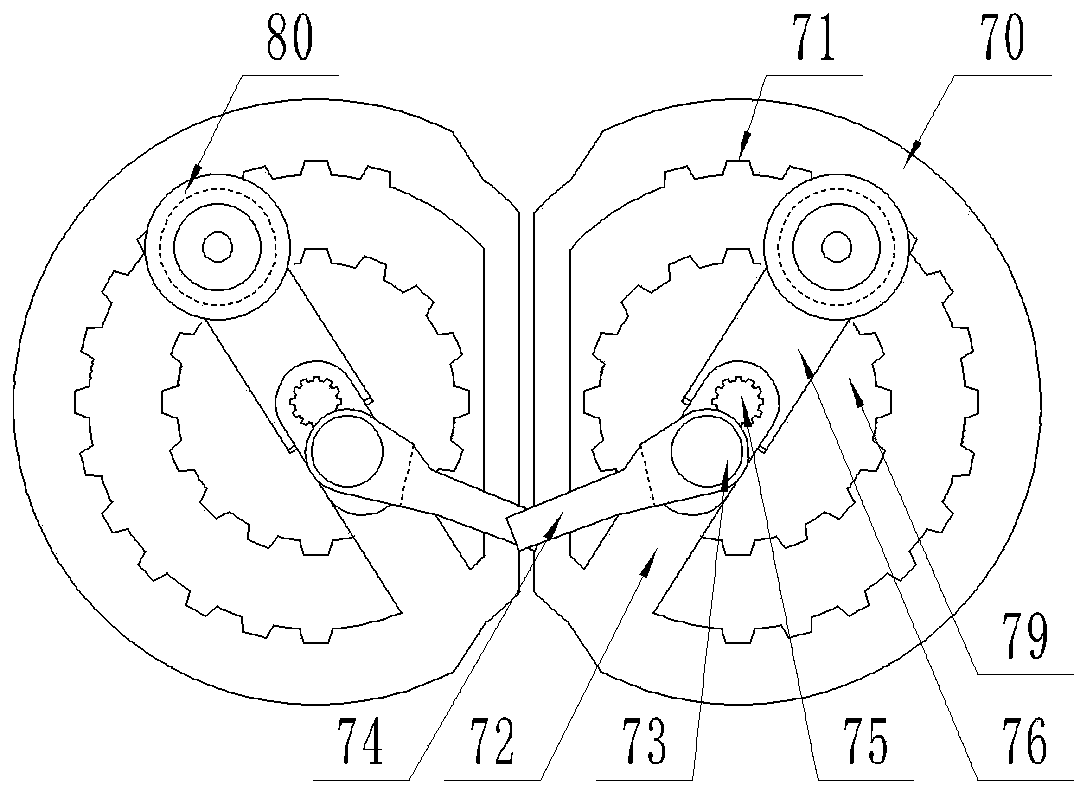

[0066] A correction mechanism on silicon wafer etching equipment, wherein, such as figure 1 As shown, it includes: a base 10 , a support seat 20 , a conveying roller 21 , a driving device 30 , a conveying belt 40 , a slide table 50 , a sliding seat 60 , a correction mechanism 70 , and a guide wheel 80 .

[0067] Two support bases 20 form a group, which are arranged opposite to each other. There is a gap between the support bases 20 . Each set of support bases 20 is installed on the left and right sides of the base 10 . The conveying rollers 21 are rotatably mounted on the support bases 20, and are installed on each set of support bases 20 respectively.

[0068] The driving device 30 is installed on the support base 20 , and the driving device 30 is power-connected to the conveying roller 21 . There are at least two conveyor belts 40 , and the conveyor belts 40 are arranged on the conveyor rollers 21 at intervals along the front and rear directions.

[0069] The slide table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com