A linear multi-motor control system

A multi-motor control, linear technology, applied in the control system, motor generator control, motor speed or torque control, etc., can solve the problems of many position control signals, difficult zero calibration, etc., to reduce the demand for digital ports , Save installation space, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

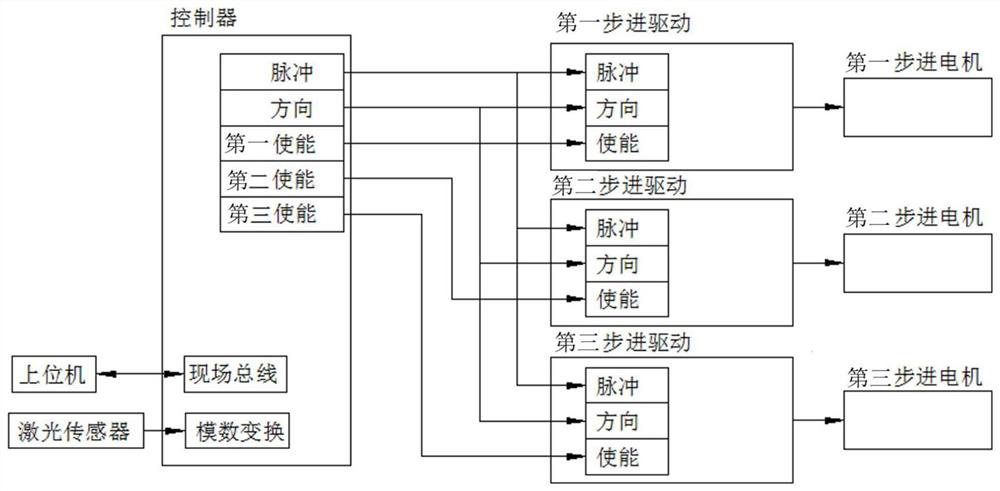

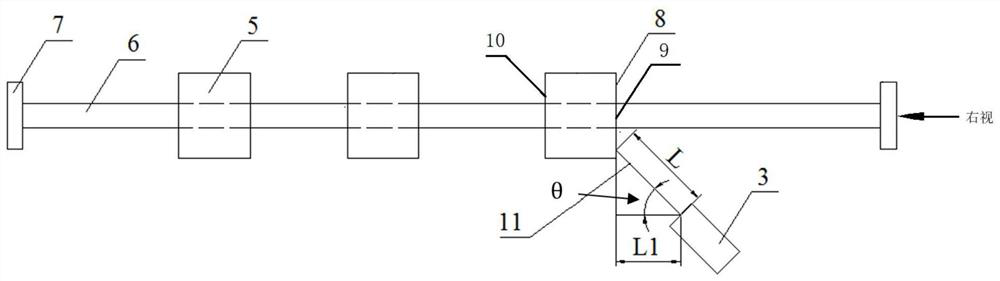

[0034] A linear multi-motor control system of the present invention includes a controller 1, a host computer 2, a laser sensor 3, several stepping drives 4 and several through-type stepping motors 5;

[0035] The controller 1 is the core of the control system, which exchanges information with the upper computer 2 through the field bus, and provides an information exchange channel for the upper computer 2 linear multi-motor motion control;

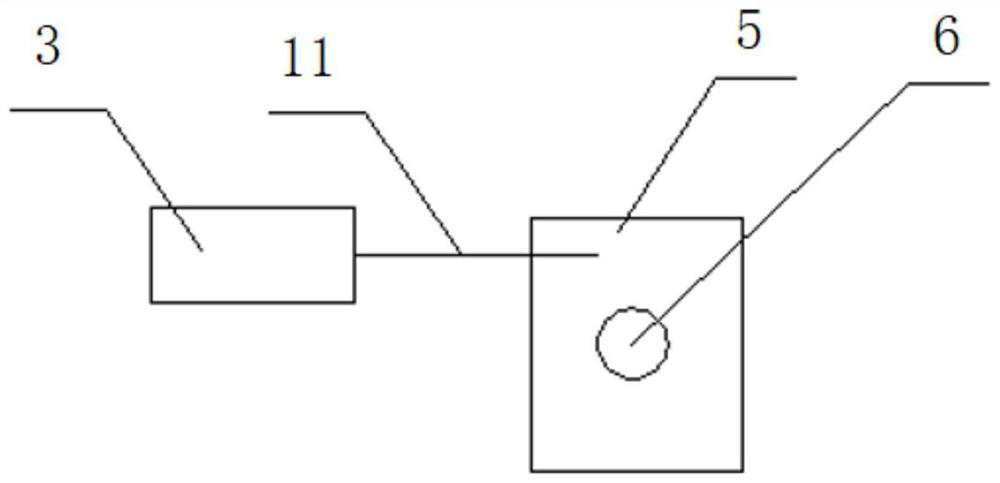

[0036] The laser sensor 3 is used for zero calibration of the initial positions of several through-type stepper motors 5;

[0037] The controller 1 realizes the data reading of the laser sensor 3 through analog-to-digital conversion;

[0038] The controller 1 realizes multi-motor linear motion control by controlling the stepper drives 4 , and each stepper drive 4 correspondingly drives a single through-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com