An error identification method for zero position calibration of swing arm crawler robot

A crawler robot and identification method technology, applied in crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of return error, inability to know error, transmission error, etc., to achieve high-precision joint position measurement, high reliability, and realization of handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

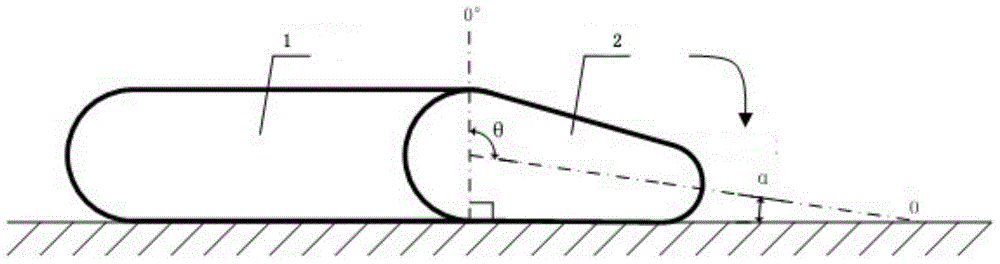

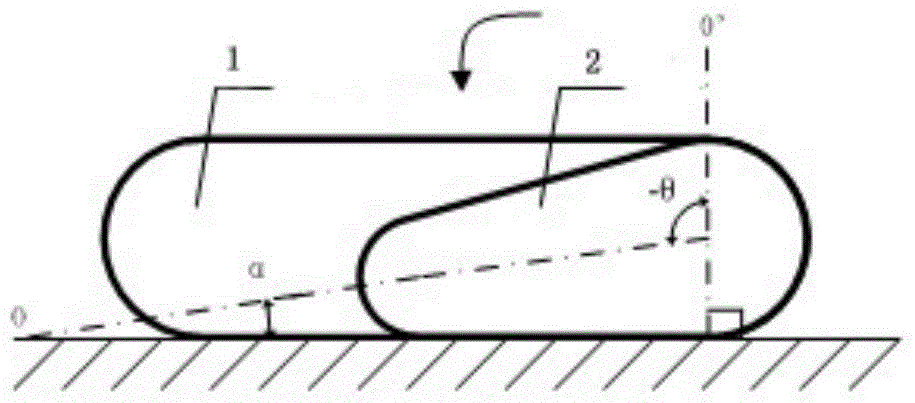

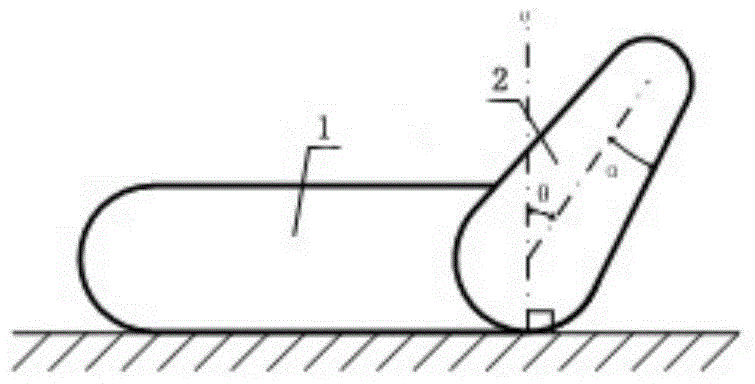

[0038] It is only assumed that the robot is a single-arm crawler structure, such as image 3 As shown, that is, the swing arm has only one movable joint. If there are multiple joints, the operation method is the same. It can be implemented at the same time without interfering with the active space, without waiting for completion one by one. The implementation steps of an accurate detection method are as follows: A. Place the robot flat on the site for preparation: place the robot on any flat space that can be supported flat, with a plane inclination ≤ 15°;

[0039] B. Friction torque detection: First, at a speed not greater than 1 / 2 of the motor rating, in speed mode, make the swing arm move continuously at an angle of about 10° within the range of the unsupported angle |θ|<90+α, and monitor the motor drive current at the same time. The average current in the state of uniform rotation is used as the drive current IF required to overcome the friction torque;

[0040] C. Positi...

Embodiment 2

[0044] Including: A. Place the robot in any plane space that can be supported horizontally, with a plane inclination ≤ 15°; B. Forward reference position detection: place the robot in any plane space that can be supported horizontally, and run in speed mode. First, make the swing arm rotate in the forward direction at 1 / 5 of the rated speed of the motor within the range of the unsupported angle |θ|<80+α, and at the same time monitor the filter drive of the motor drive current after a low-pass filter equivalent to the bandwidth of the speed loop The absolute value of the current ICF1, when the ICF1 appears more than 2 times the step mutation as the trigger source, record the encoder measurement value at this moment as the reference position value β1, and then control the reverse rotation of the swing arm to the starting point to stop;

[0045] C. Reverse reference position detection: After step B is completed, control the swing arm to rotate in the reverse direction at 1 / 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com