A speed control method and control system for a motor

A speed control and acceleration technology, which is applied in the direction of AC motor acceleration/deceleration control, motor parameter estimation/correction, etc., can solve the problems of insufficient speed response, low acceleration efficiency, long time required for distance, etc., to improve machining Speed and efficiency, solve the effect of insufficient speed response, smooth connection and no impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

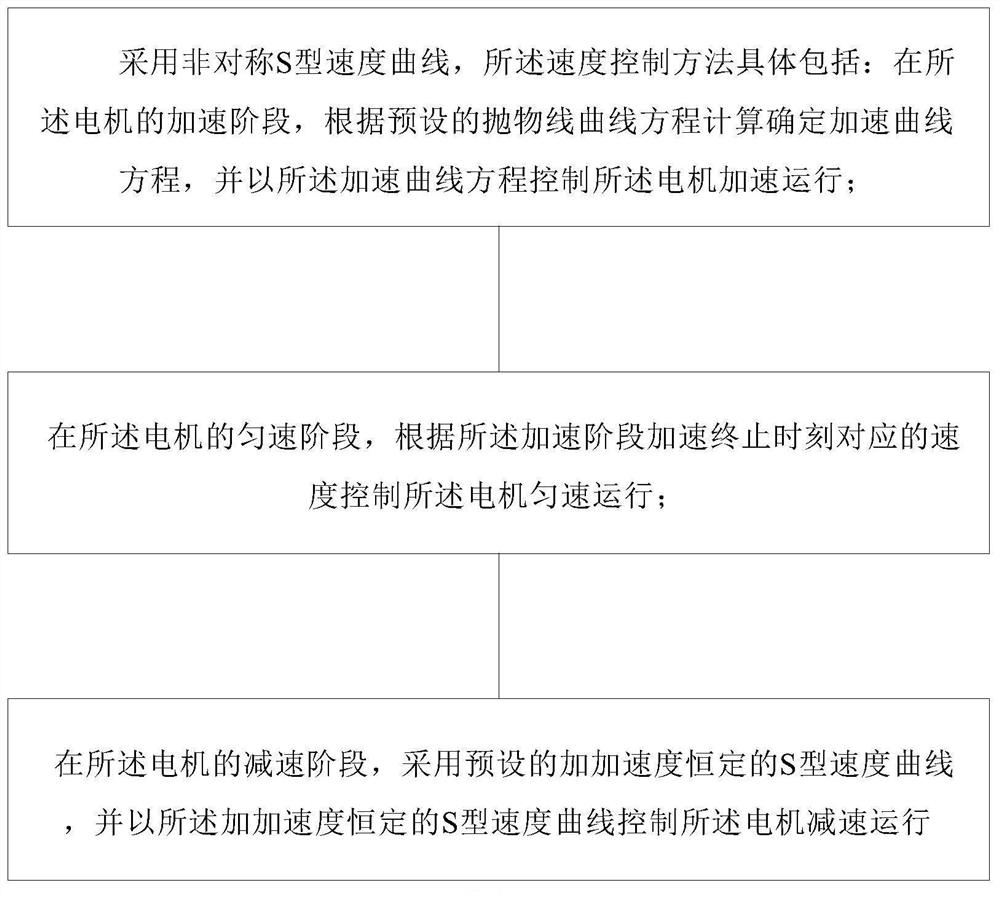

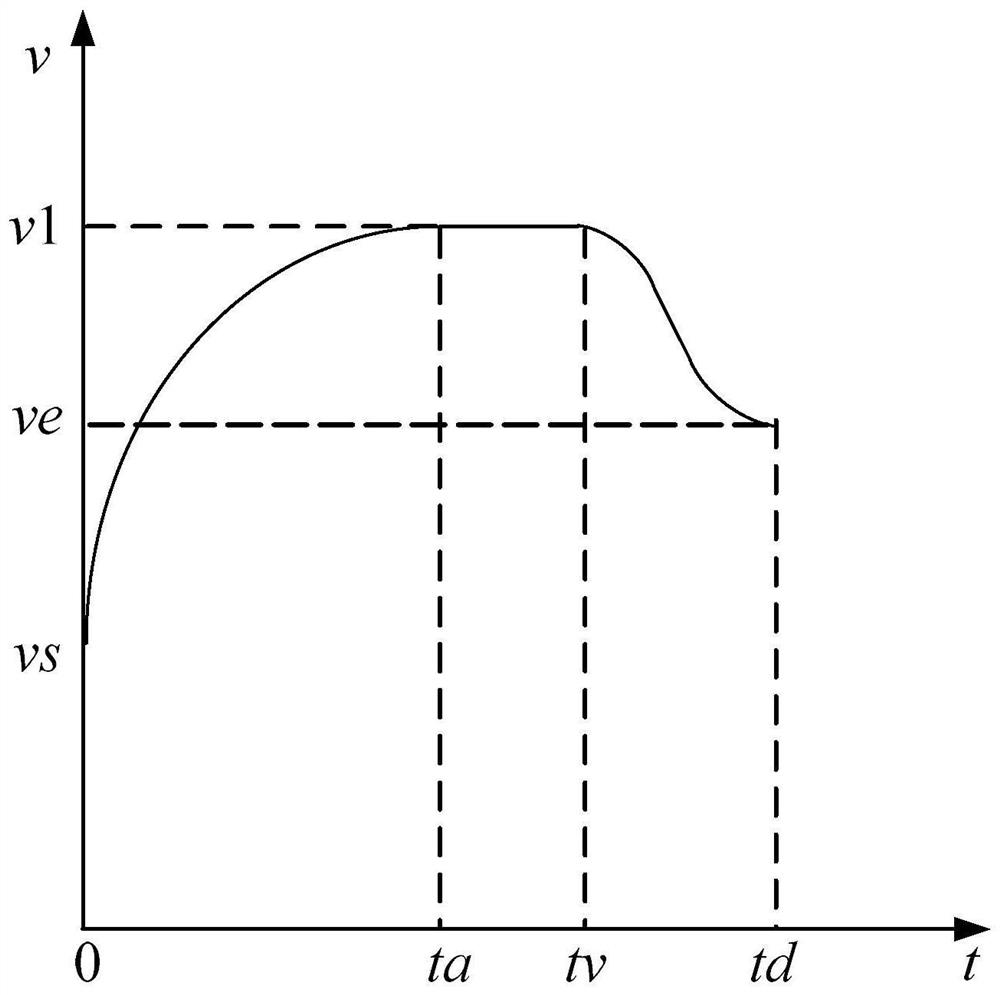

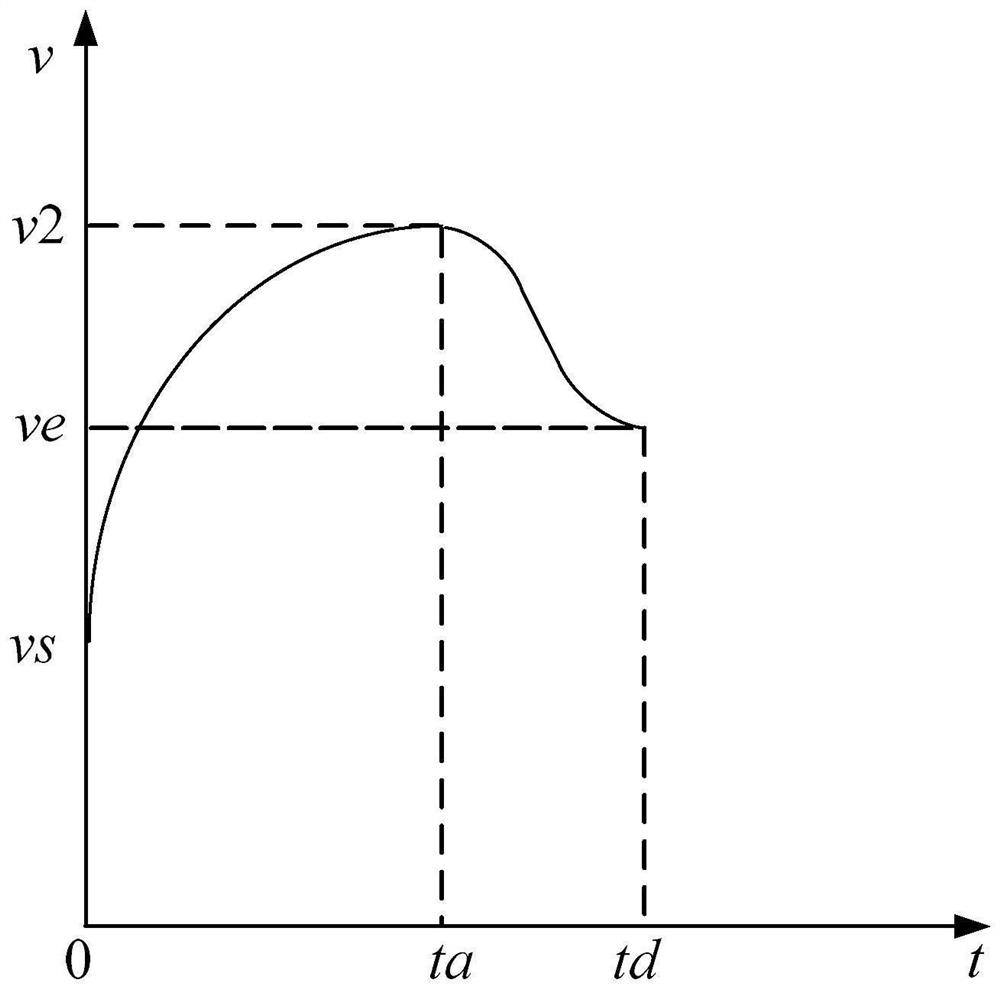

[0061] like figure 1 and figure 2 As shown, the first aspect of the present invention provides a speed control method for a motor, which adopts an asymmetric S-shaped speed curve. The speed control method specifically includes: in the acceleration stage of the motor, calculating and determining the acceleration curve according to a preset parabolic curve equation Equation, and control the motor to accelerate with the acceleration curve equation. In the constant speed stage of the motor, the motor is controlled to run at a constant speed according to the speed corresponding to the acceleration termination time in the acceleration stage. In the deceleration stage of the motor, a preset S-shaped speed curve with constant jerk is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com