Peanut vine soil removing conveying and back laying device for peanut digging and back-laying machine

A technology for conveying devices and peanut seedlings, which is applied to excavators, digging harvesters, applications, etc., can solve the problems of high labor intensity, increased labor intensity, and affecting the quality of peanuts, and achieve the effect of being convenient for drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

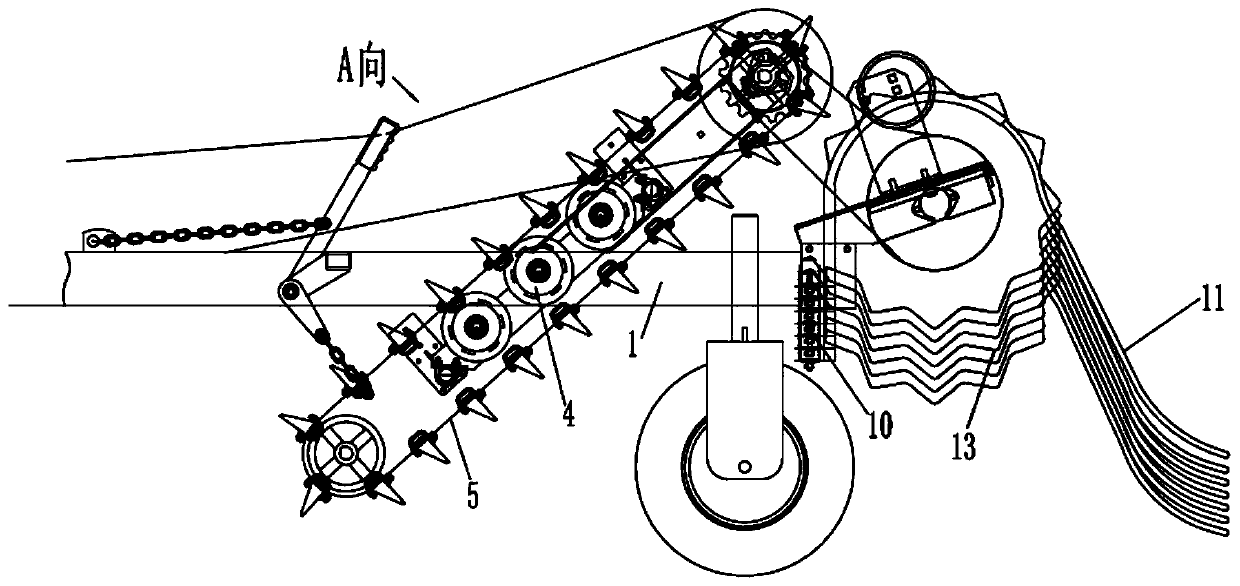

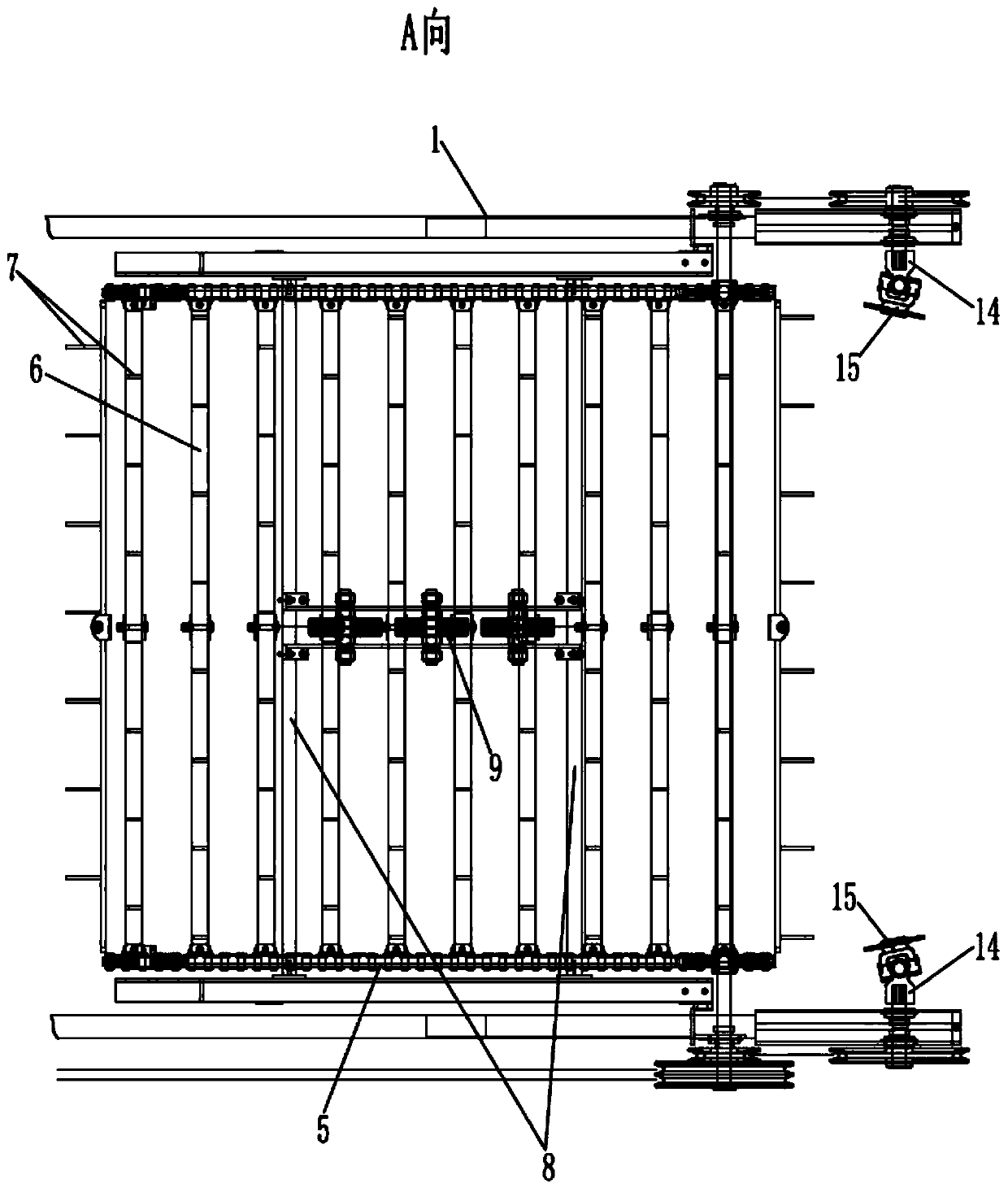

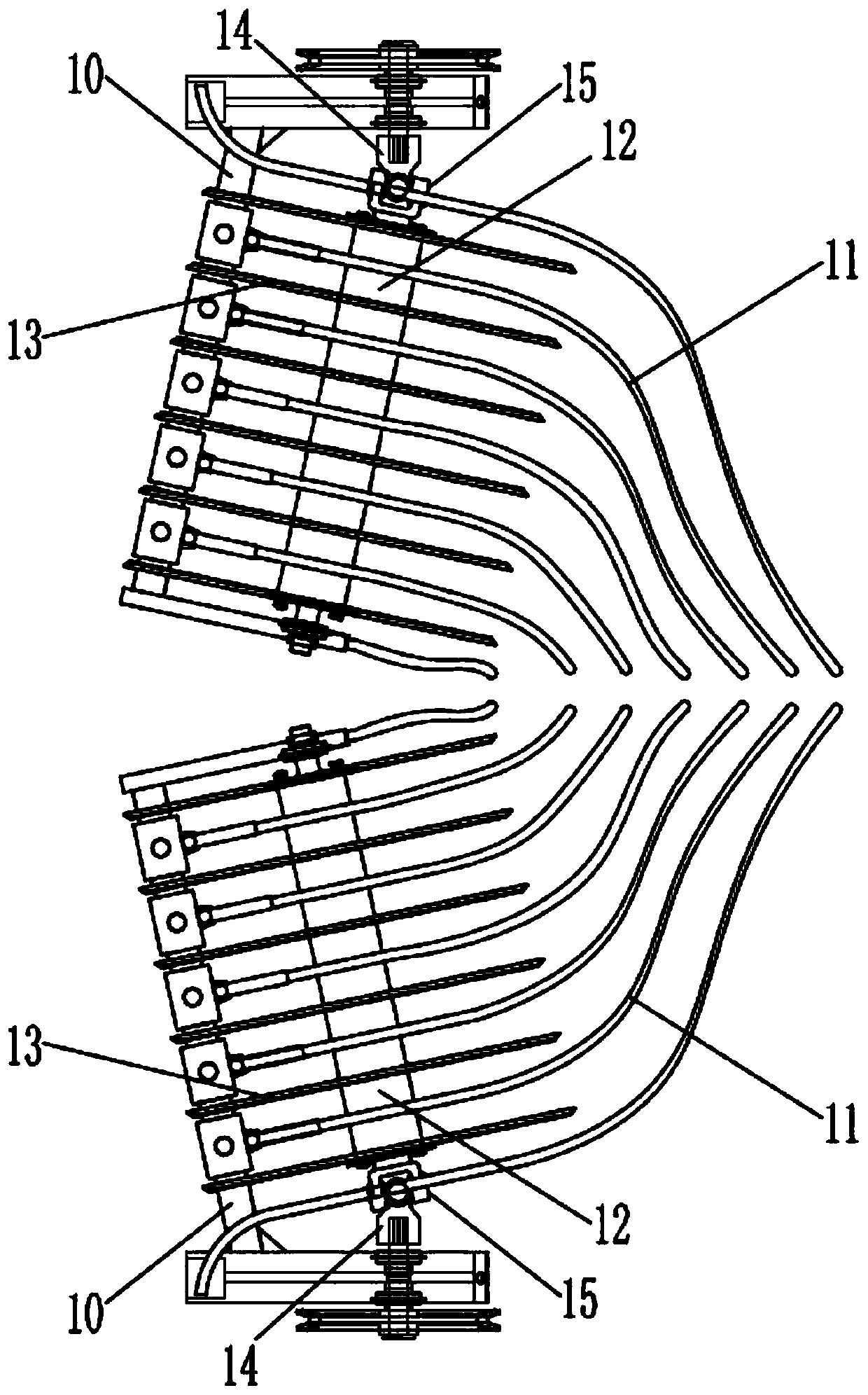

[0025]The present invention is used in conjunction with a peanut excavation transport device. The peanut excavation transport device is fixed on the front end of the peanut seedling soil removal transport device through a suspension frame 1. The peanut excavation transport device includes two shovel blades 2 and two shovel blade 2 The peanut seedling conveying guide structure 3 at the rear end, the two spatulas 2 are left-right symmetrical structures, the outer ends of the two spatulas 2 are in the front, and the inner ends are in the rear, so as to gather the shoveled peanut seedlings into the peanut seedling conveying channel The front end of the peanut seedling conveying guide structure 3 is a guide rod fixed at the rear end of the spatula 2 at intervals, and each guide rod stretches backward to the front end of the peanut seedling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com