Fruit jelly and preparation method thereof

A technology of jelly and jam, which is applied to the functions of food ingredients, food ingredients as taste improvers, food science, etc. It can solve the problems of food quality and safety, product quality deterioration, difficult to achieve commercial aseptic shelf life, etc., to achieve the taste of the entrance Excellent, guaranteed quality, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 adopts the jelly prepared by process of the present invention

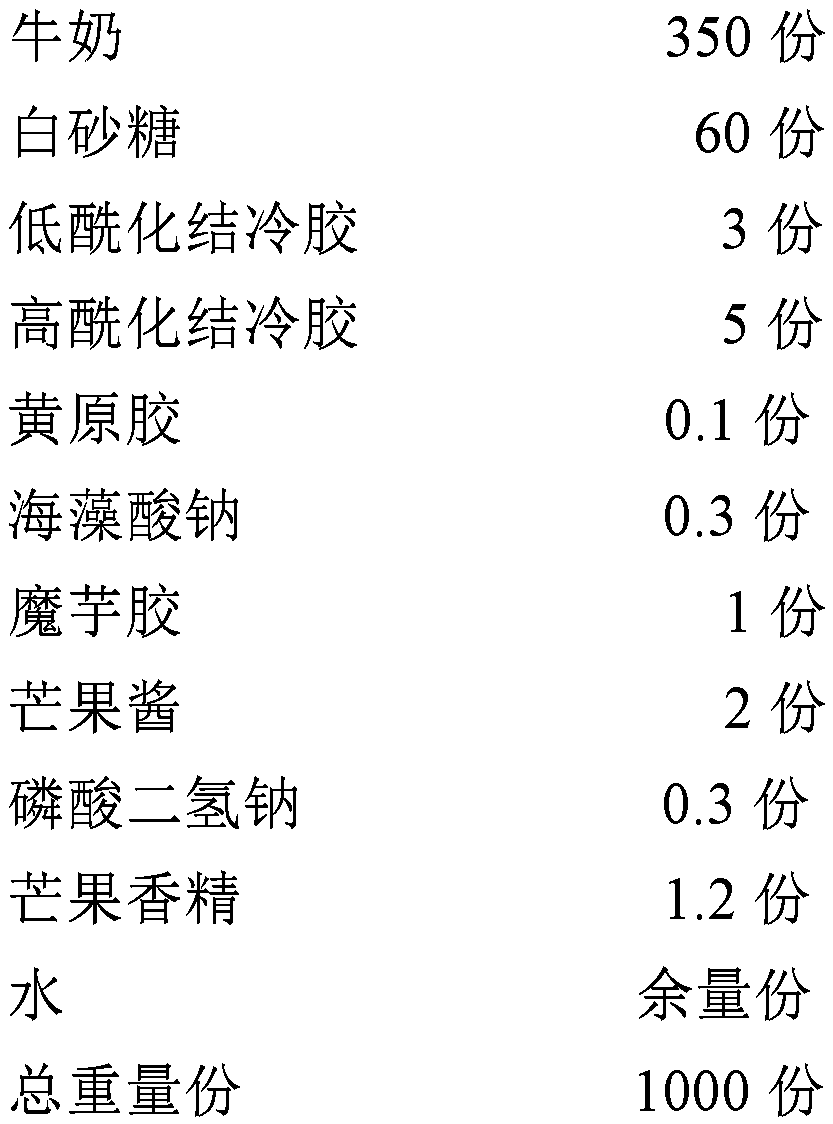

[0073] 1. Preparation of mango-flavored milk jelly

[0074] Adopt above-mentioned specific process step of the present invention, and adopt following batching ratio.

[0075]

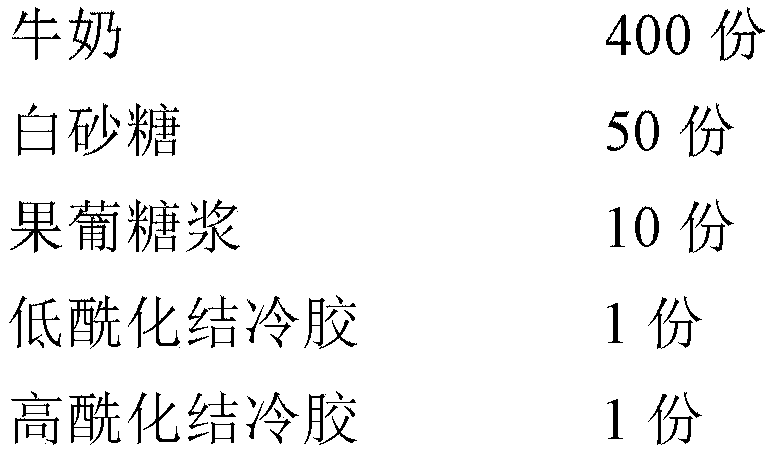

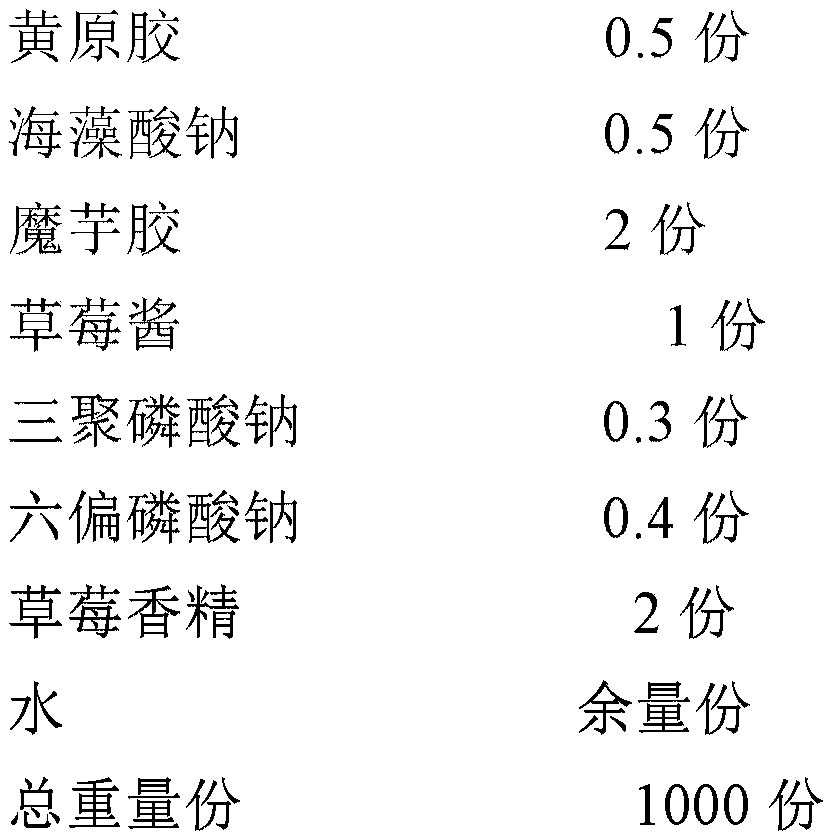

[0076] 2. Preparation of strawberry flavored milk jelly

[0077] Adopt above-mentioned specific process step of the present invention, and adopt following batching ratio.

[0078]

[0079]

[0080] 3. Preparation of passion fruit flavored milk jelly

[0081] Adopt above-mentioned specific process step of the present invention, and adopt following batching ratio.

[0082]

[0083] 4. Preparation of passion fruit flavored milk jelly

[0084] Adopt above-mentioned specific process step of the present invention, and adopt following batching ratio.

[0085]

[0086]

Embodiment 2

[0087] Embodiment 2 adopts the jelly prepared by prior art technology

[0088] 1. Adopt the concrete process step of above-mentioned prior art, and adopt following batching ratio.

[0089]

[0090] 2. Adopt the specific process steps of the above-mentioned prior art, and adopt the following batching ratio.

[0091]

Embodiment 3

[0092] The detection of protein content in embodiment 3 jelly

[0093] The production process of the invention can realize the production of neutral dairy jelly, and the final product can meet the requirement of more than 1.0% protein. The detection of protein content adopts the national standard GB 5009.5, National Food Safety Standard, Determination of Protein in Food, the current version number is 2016 version. The test results are shown in Table 1.

[0094] Table 1

[0095] Example number Protein content (g / 100g) Example 1.1 1.05 Example 1.2 1.20 Example 1.3 1.50 Example 1.4 2.40 Example 2.1 2.40 Example 2.2 2.40

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com