Rotor painting machine

A rotor and fuselage technology, applied in the field of rotor painting machines, can solve the problems of difficult quality assurance, affecting people's health, high labor intensity, etc., and achieve the effects of convenient debugging and maintenance, high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

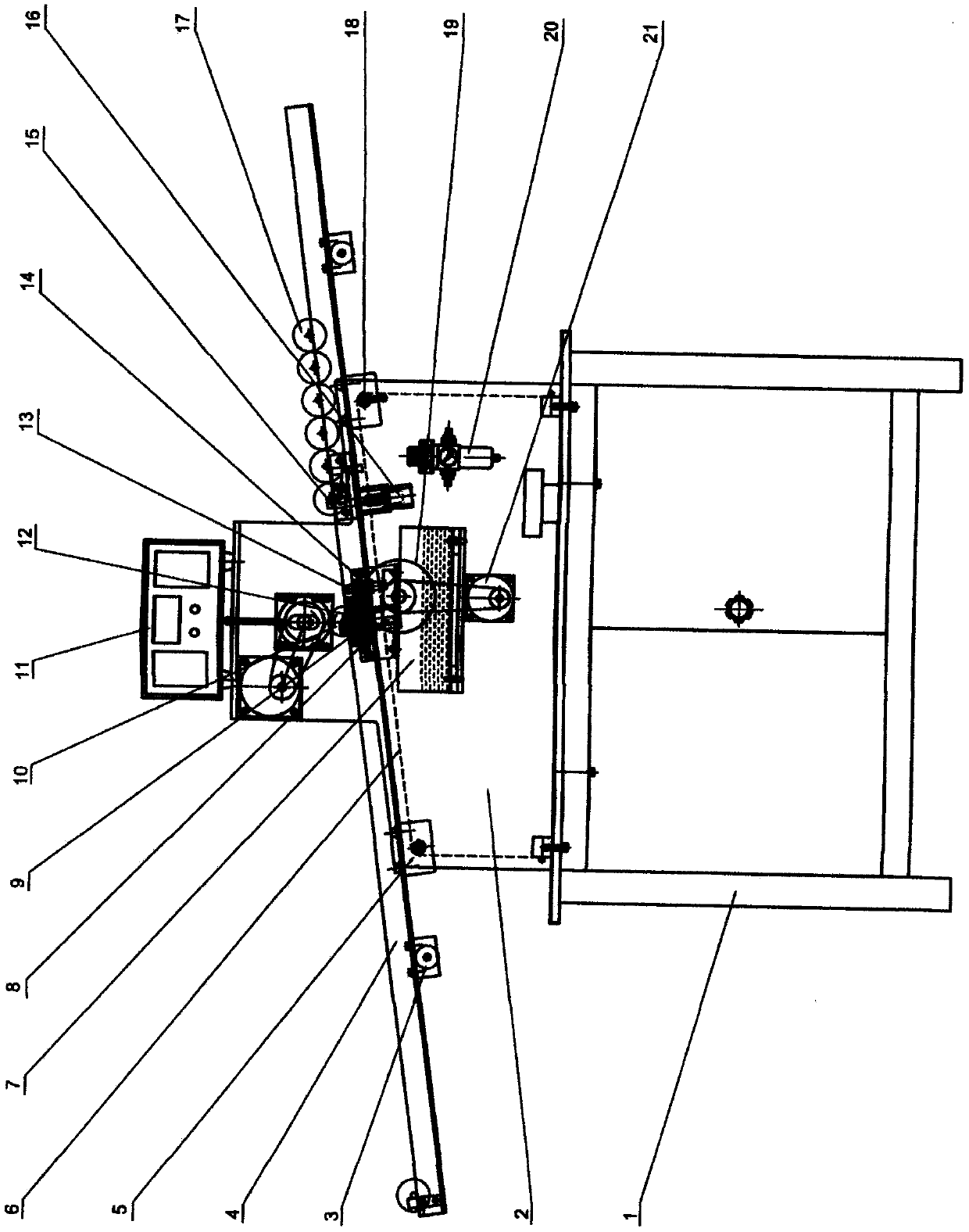

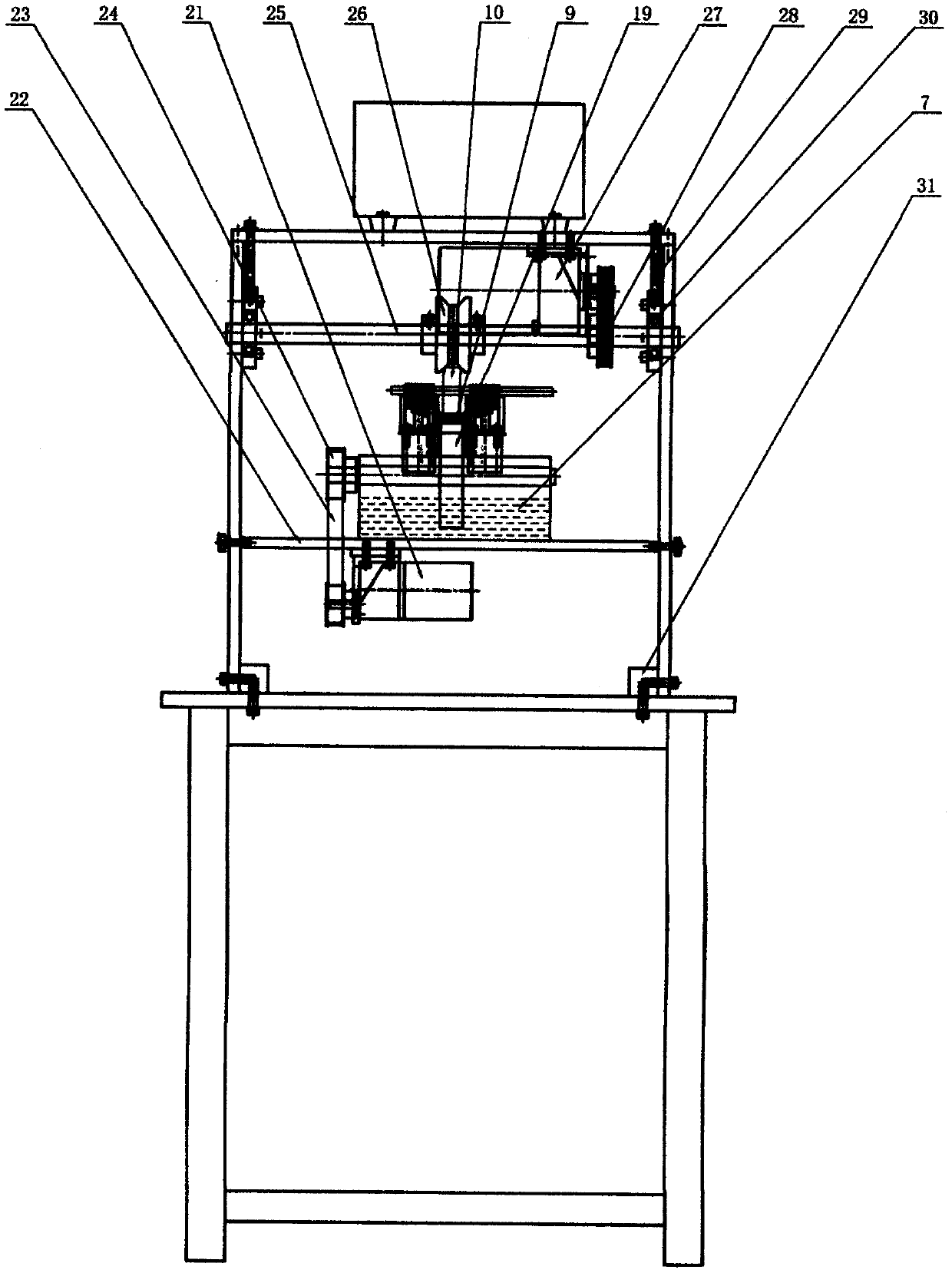

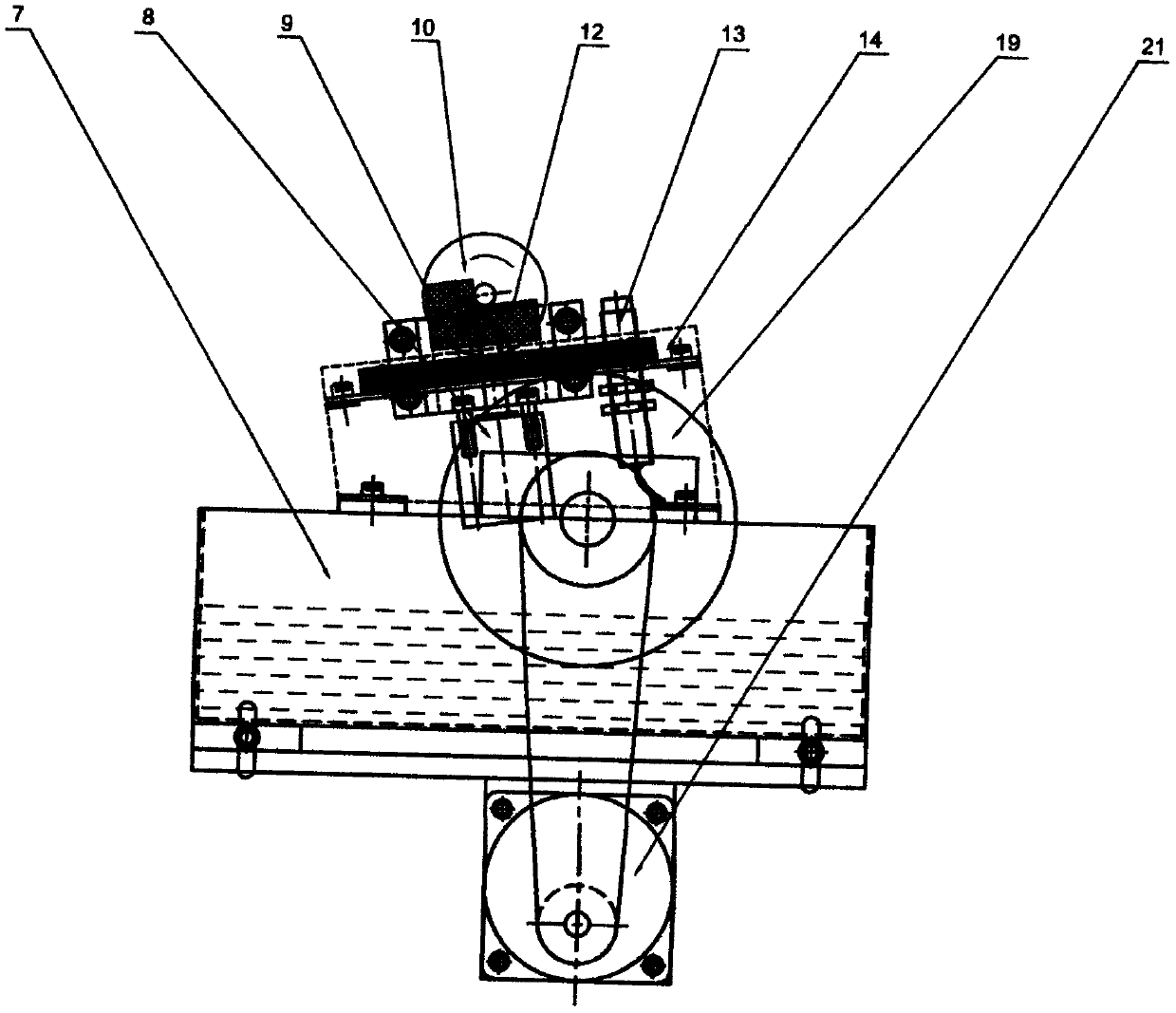

[0014] The invention is realized in the following ways:

[0015] The invention uses the guide rail (4) and the cylinder to automatically load and unload, the rotor (10) is rolled into the oil cotton box (14), the motor drives the rotor (10), the paint wheel (19) is supplied, and the rotor rubs the oil cotton (9) to apply Painted, its characteristics: the machine (1) is equipped with a fuselage (2), the fuselage (2) is formed by connecting two plates, a connecting rod (18), and a connecting block (31). (2) A guide rail (4) is installed inside. The guide rail (4) is composed of: a support (3), a support (5), a blocking cylinder (8), a block (12), a blocking device (15), a blocking cylinder (16), the paint box part (7) and oil cotton box (14) are installed under the guide rail. The paint box part (7) is composed of: motor (21), support plate (22), belt (23), belt The wheel (24), the rotor drive wheel (26), the motor (29), the paint wheel (19), and the oil cotton box (14) are compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com