Control method and system for roll-bending force of skin-pass mill

A control method and technology of roll bending force, which is applied in the field of control method and control system of roll bending force of skin pass mill, can solve inaccurate, hot-dip coated strip head or tail wave shape, untimely bending force, etc. problems, to achieve the effect of reducing the probability of failure, reducing strip edge waves, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

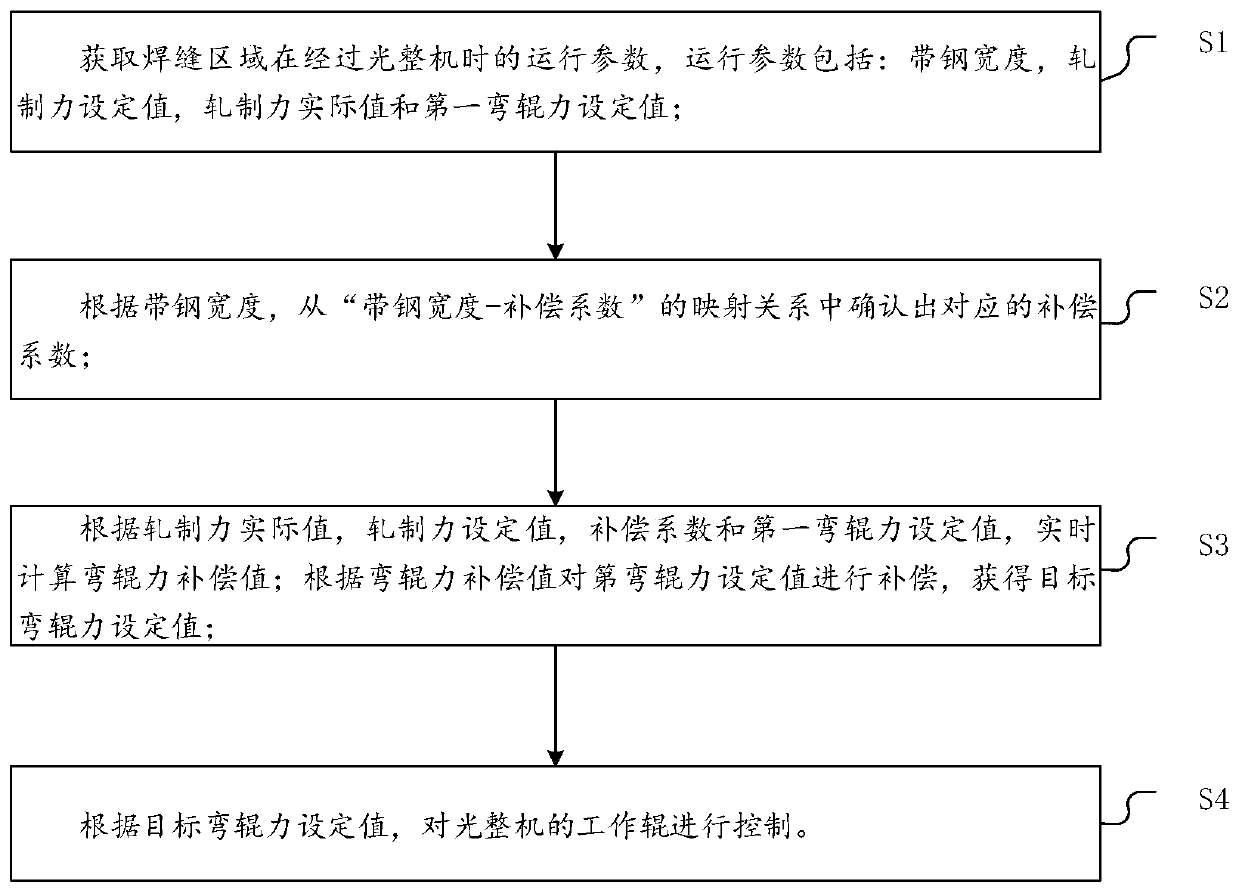

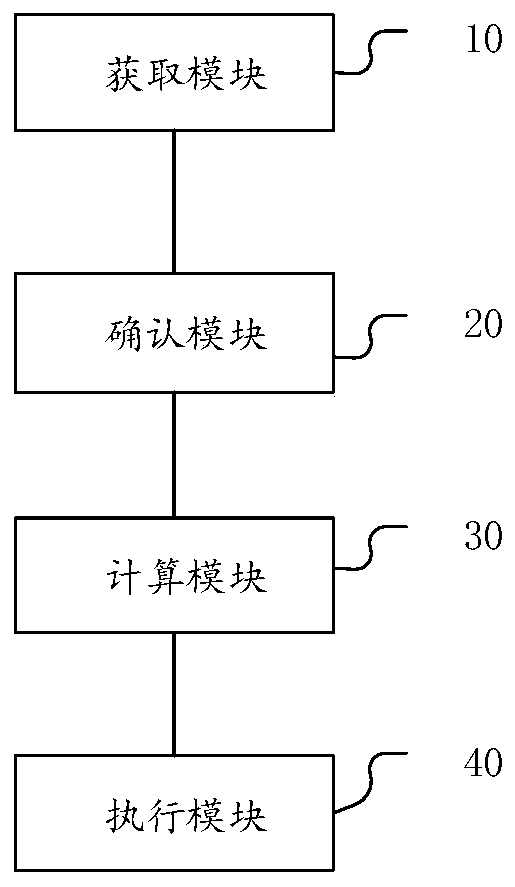

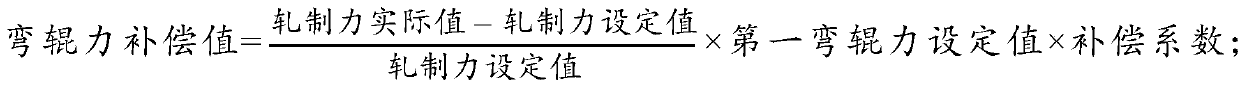

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0049] In simple terms, the bending control process of the skin pass machine is to control the bending cylinder in the hydraulic block to act on the work roll bearing seat of the skin pass machine to change the bending state of the work roll, thereby adjusting the crown of the work roll. When the positive roll bending force generated by the bending oil cylinder at the roll neck of the work roll is greater than the negative roll bending force, the work roll will produce positive roll bending, making the middle part of the work roll more convex relative to the galvanized sheet, and the center of the galvanized sheet The pressure of the position increases; when the negative bending force is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com