A mold for cross-standard production of high-density large-diameter polyethylene pipes

A polyethylene pipe and large-diameter technology, which is applied in household appliances, other household appliances, applications, etc., can solve problems such as the inability to realize the pressurization process, and achieve the effects of technical improvement, reduction of raw material sag, and uniform tissue state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

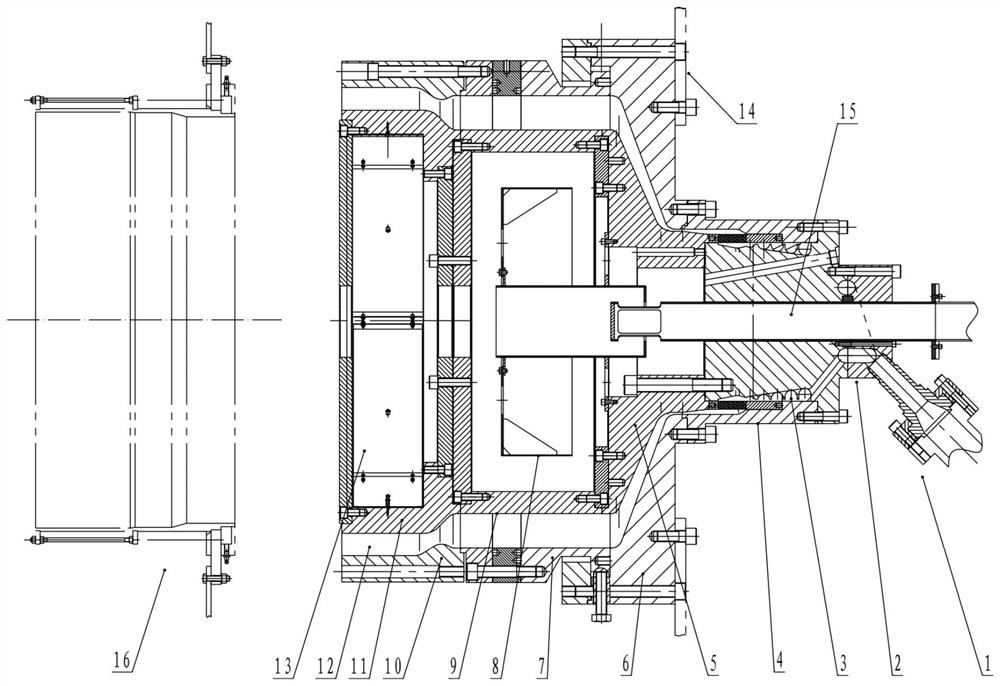

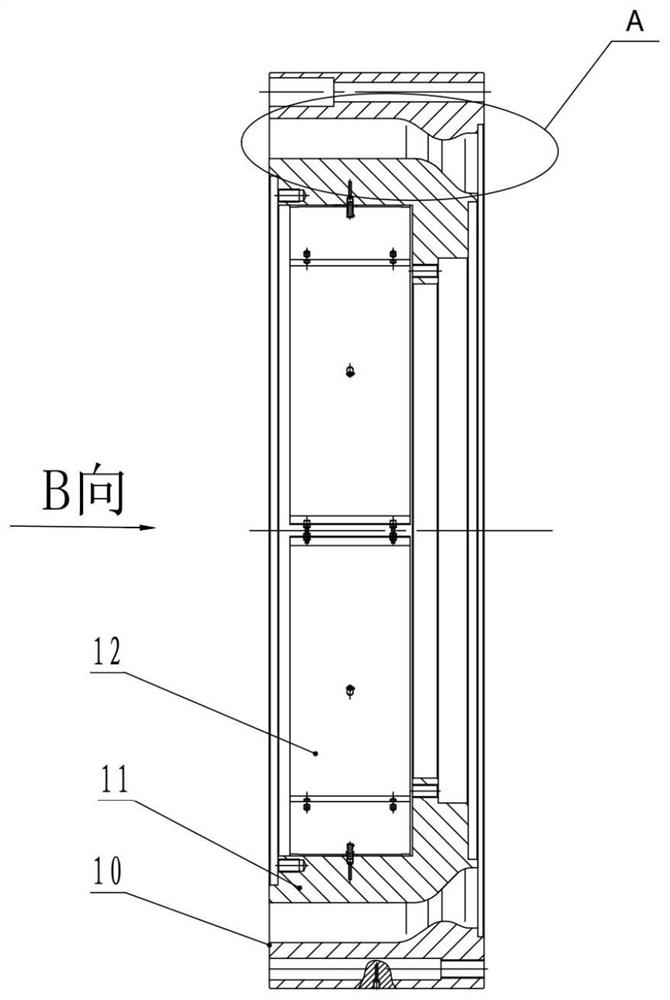

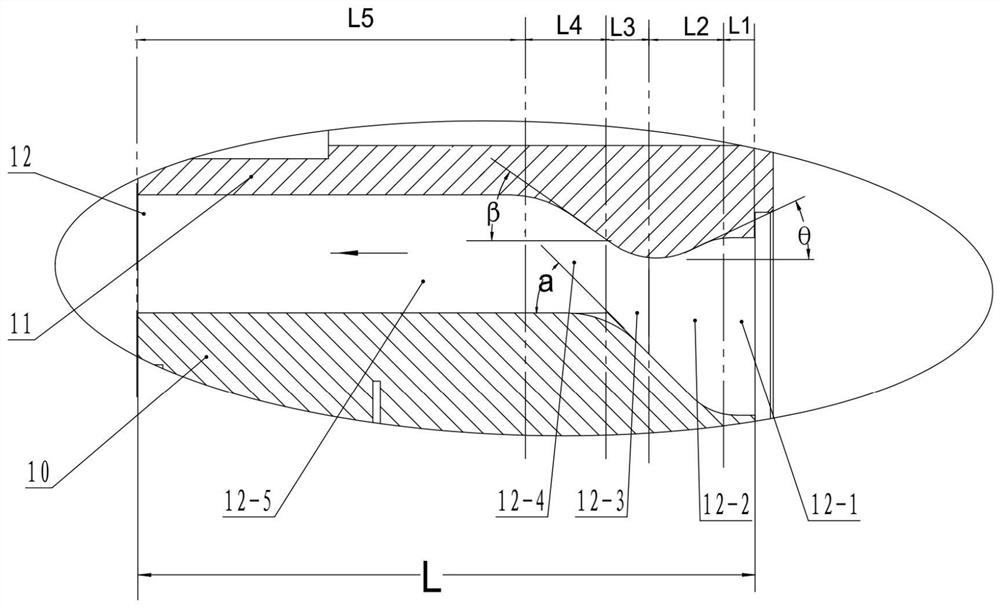

[0020] see figure 1 , the present invention comprises base mold and the die 10 that connects base mold, core mold 11. The basement membrane is supported by the base mold mounting base 15, and the base mold includes a die transition 7, a mandrel transition 9, a mold end cap 2, a basement membrane helical body jacket 4, an inner mold expansion 5, and an outer mold expansion 6. The die transition set is outside the transition of the mandrel, the die transition is connected to the die, and the mandrel is transitionally connected to the mandrel. The mold end cover 2 located at the right end of the base film is connected to the feed port 1, and the polyethylene material in molten state after heating enters the base mold through the feed port, and the polyethylene material in the front section of the base film passes through the mesh basket 3 corresponding to the base film helicoid outer coat 4, Then through the gap between the inner mold expansion 5 and the outer mold expansion 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com