Intelligent electronic control ozone combustion-supporting type electric turbo-charging system of automobile

A combustion-supporting, ozone-based technology, applied in the direction of charging systems, ozone preparation, combustion engines, etc., can solve the problems of short engine life, increase engine performance, and blocked engine intake, so as to solve the lag of power output response and shorten the ignition lag Period, the effect of increasing engine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

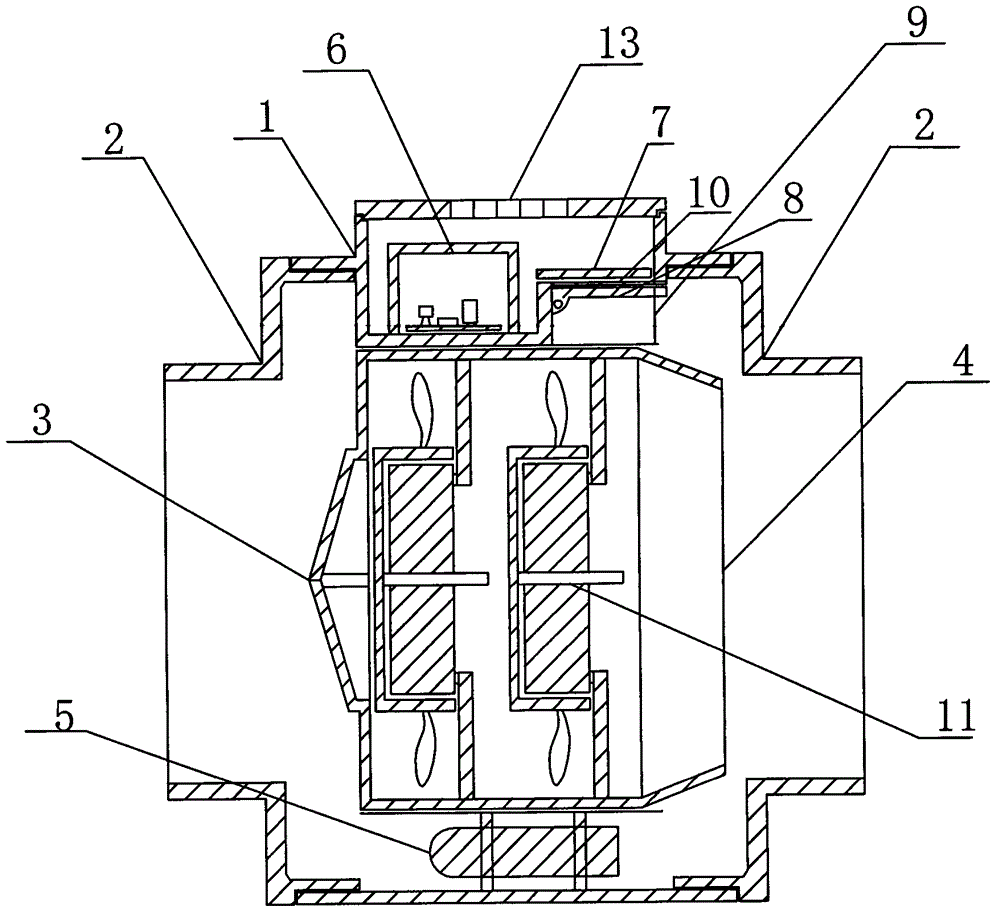

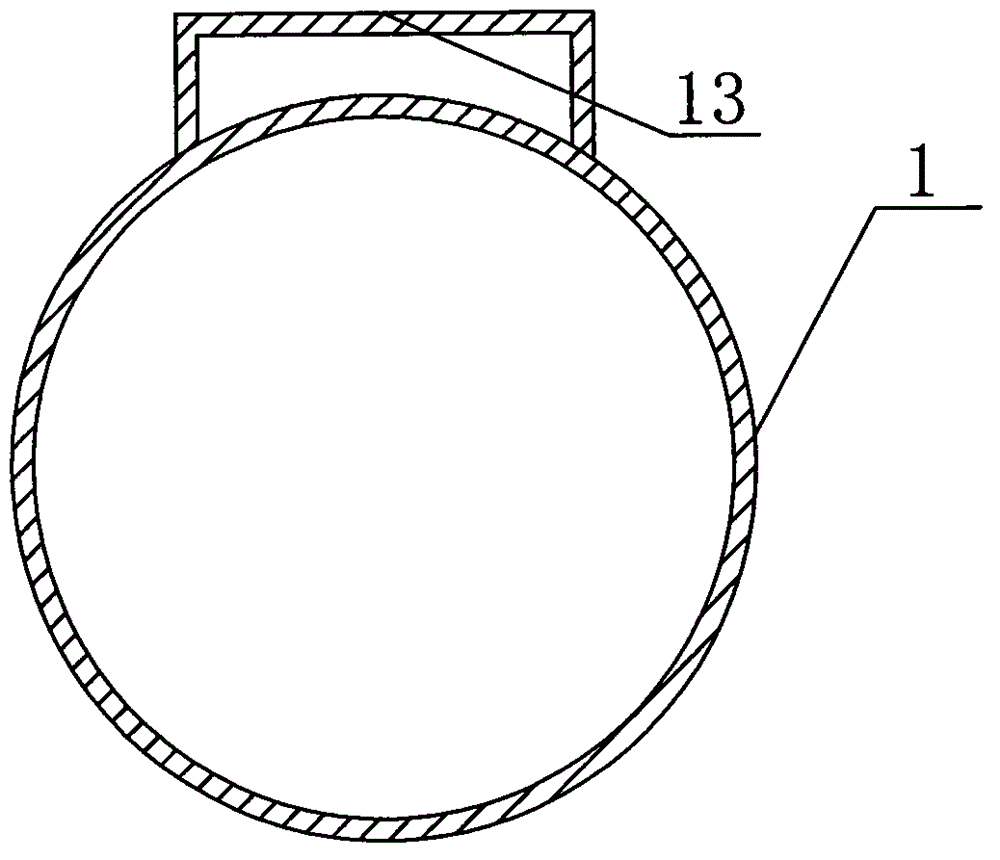

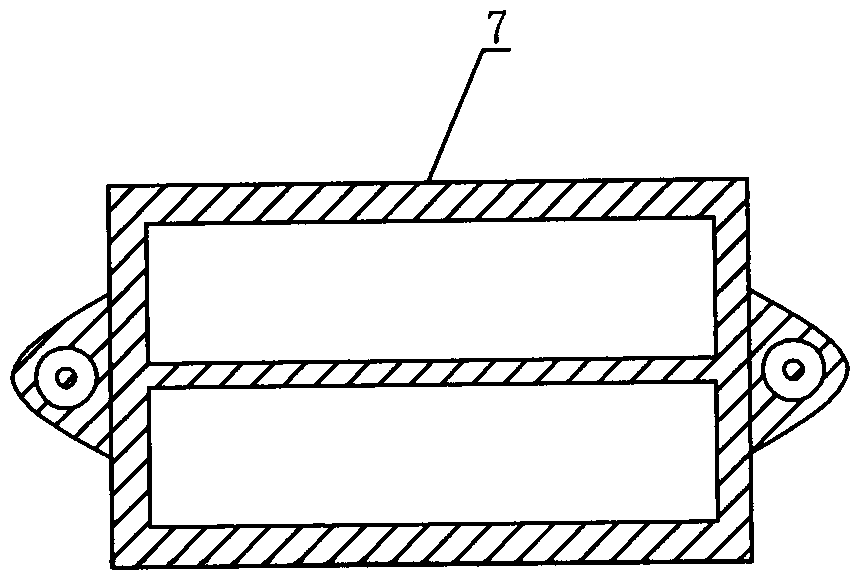

[0020] As shown in the figure, the present invention is an intelligent electronically controlled ozone combustion-supporting electric turbocharging system for automobiles. Its main body includes a working cabin 1, a turbo blower 11 and an ozone generator. Including deflector cone 3 and fairing 4; the turbine fan cover is installed in the working cabin 1, and the ozone generator is divided into two parts: the ozone tube 5 and the ozone power supply 6, wherein the ozone power supply 6 is installed in the working cabin 1 with a bypass air path 13 On one side, the ozone tube 5 is installed on the other side, and the ozone tube 5 and the ozone power supply 6 are connected by a high-voltage silicone wire 12; the working cabin 1 is provided with a short-circuit air circuit 9, and a damper 8 is provided at the short-circuit air circuit 9 , The air door 8 is equipped with a filter cotton 10, and the filter cotton 10 is fixed on the air door 8 through the pressure plate 7; the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com