Powder treatment device for agricultural grain processing

A processing device and grain technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of grain mixed with dust, not easy to separate, and affected by deep processing of grain, and achieve the promotion of raising, the method is simple and effective, and the improvement of The effect of vacuuming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

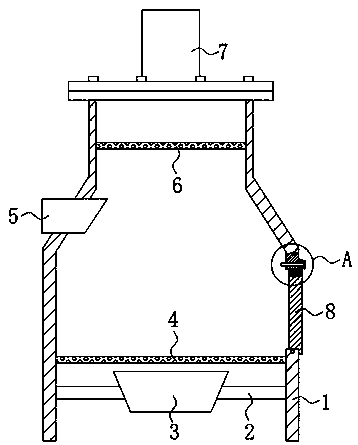

[0022] refer to Figure 1-2 , a powder processing device for agricultural grain processing, including a body 1, the body 1 adopts an inverted funnel-shaped structure, and a feeding pipe 5 for grain feeding is installed at the upper and middle part of the body 1. The upper and lower parts of the body 1 A first filter plate 4 for air intake and preventing grain from falling and a second filter plate 6 for air outlet and preventing grain from passing through are respectively installed on the side inner wall. The flange piece is installed with an air outlet pipe 7, which is connected to the air inlet pipe of the air compressor. The bottom end of the body 1 is installed with a support frame 2 for carrying the air inlet funnel 3, and the outer diameter of the support frame 2 is the same as the body 1. The inner diameters of the corresponding positions are equal, and the air inlet funnel 3 is located at the lower end of the first filter plate 4 .

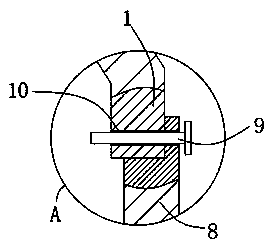

[0023] Further, the body 1 is prov...

Embodiment 2

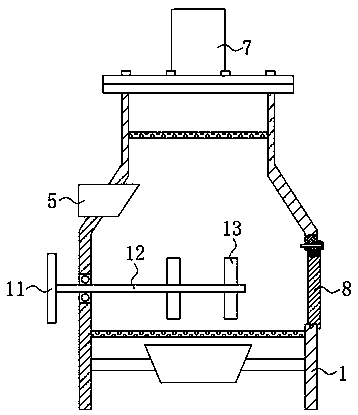

[0026] refer to image 3 , Embodiment 2 adds a material turning mechanism on the basis of retaining Embodiment 1, and improves the dust removal effect through manual-driven physical tumbling.

[0027] The material turning mechanism includes a stirring shaft 12, a turntable 11 and a plurality of stirring blades 13. The stirring blades 13 are welded on the stirring shaft 12 at equal distances. The turntable 11 is welded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com