High-efficiency tempering production method for thin tempered plate

A production method and thin-gauge technology, which is applied in the field of thin-gauge steel plate tempering technology, can solve the problems of large safety distance, shorten the safety distance, and increase the average thickness of the tempered plate, so as to increase the thickness, shorten the safety distance, and improve the tempering The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In order to make the present invention clearer, a high-efficiency tempering production method for thin-gauge tempered plates of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not used for limit the invention.

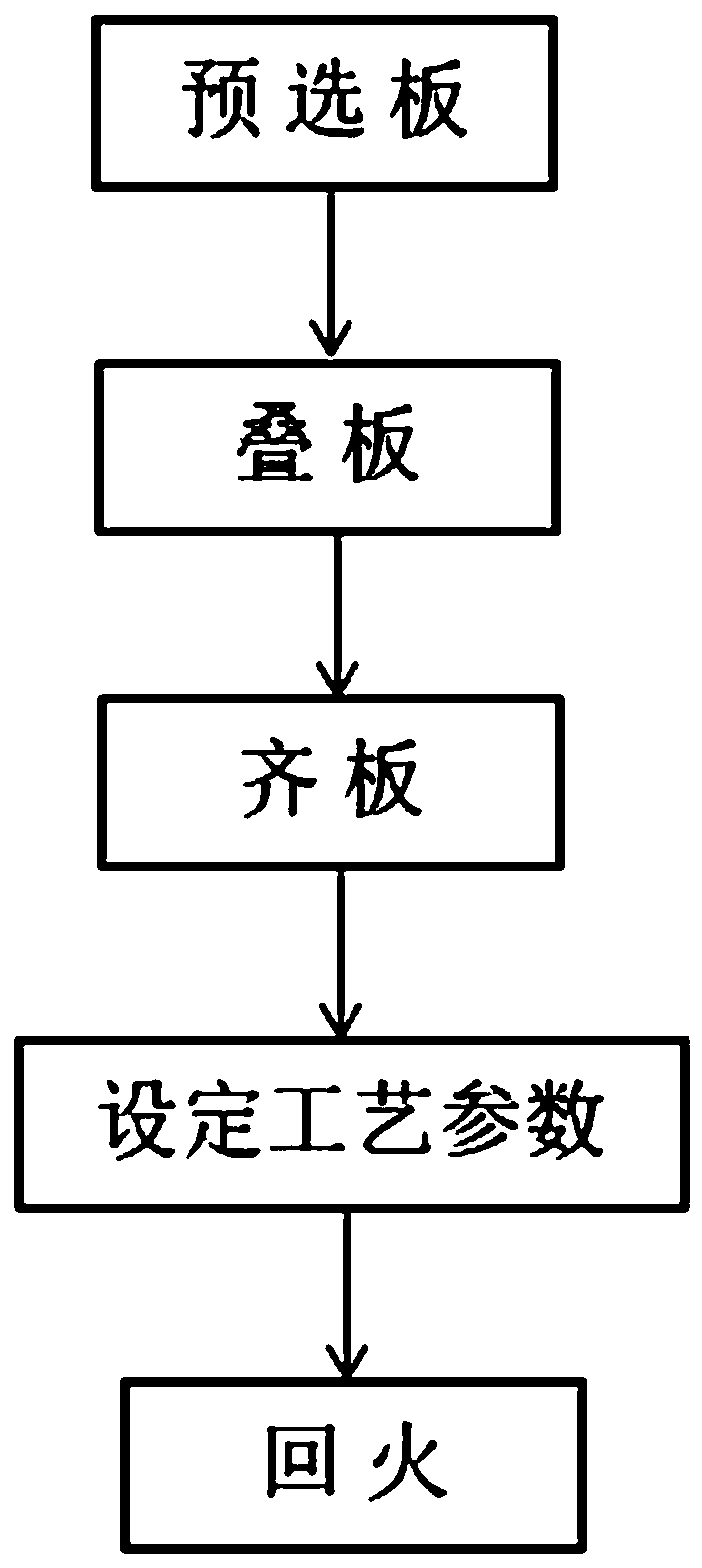

[0023] Take the Q960 steel plate with specifications of 5mm*3000mm*10000mm and the effective length of the heat treatment furnace as 90m as an example, see figure 1 , the specific steps of using the method of the present invention to efficiently temper the thin plate of this specification are as follows, it is characterized in that it includes:

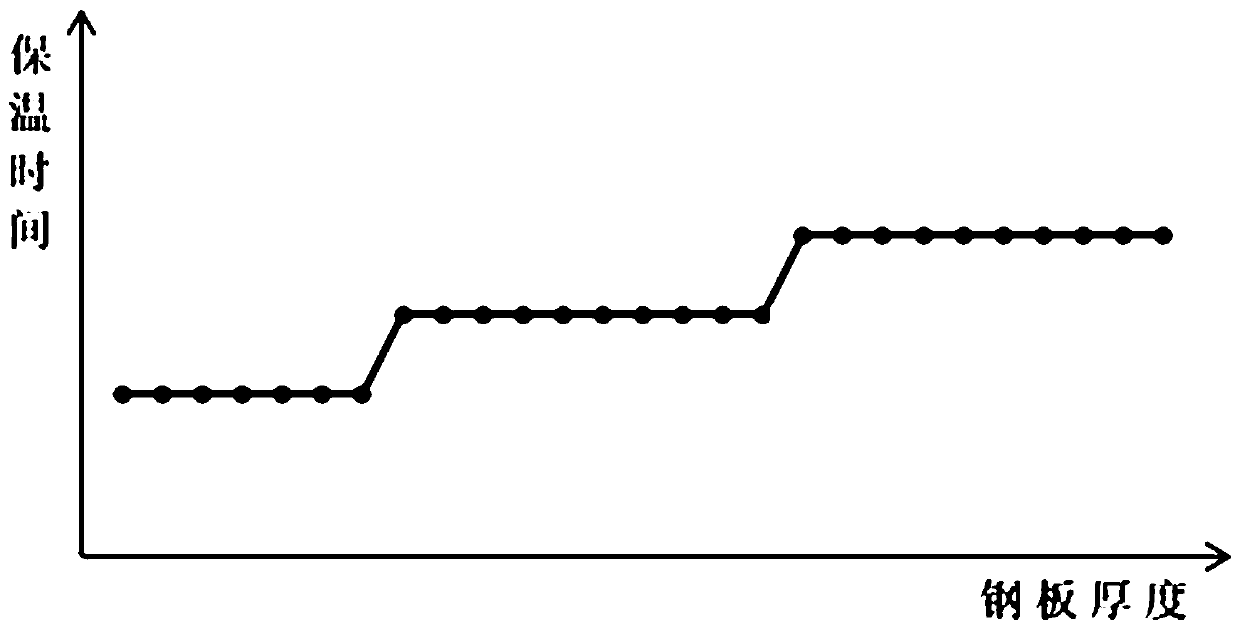

[0024] (1) Select three pieces of Q960 of 5mm*3000mm*10000mm, the flatness of each Q960 is ≤12mm / m and there is no edge wave, the temperature of each sheet is 600℃, and the holding time is 30min;

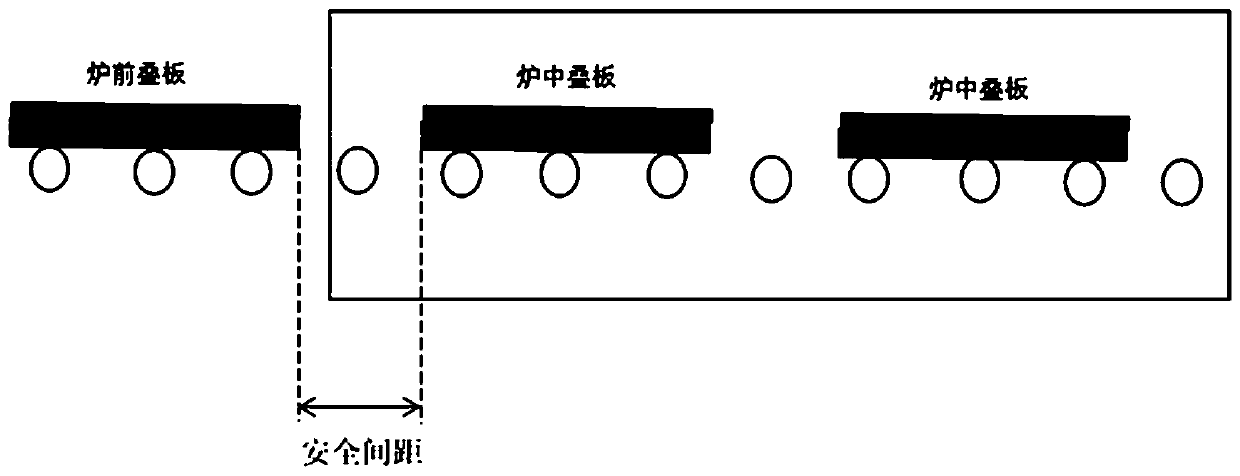

[0025] (2) Before entering the furnace, align and stack three Q960 sheets he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com