Temporary fixing device for precast column of prefabricated framework structure

A frame structure and temporary fixing technology, which is applied in the on-site preparation of building components, building construction, connection parts of formwork/template/work frame, etc., can solve the problem of easy damage to the seat slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

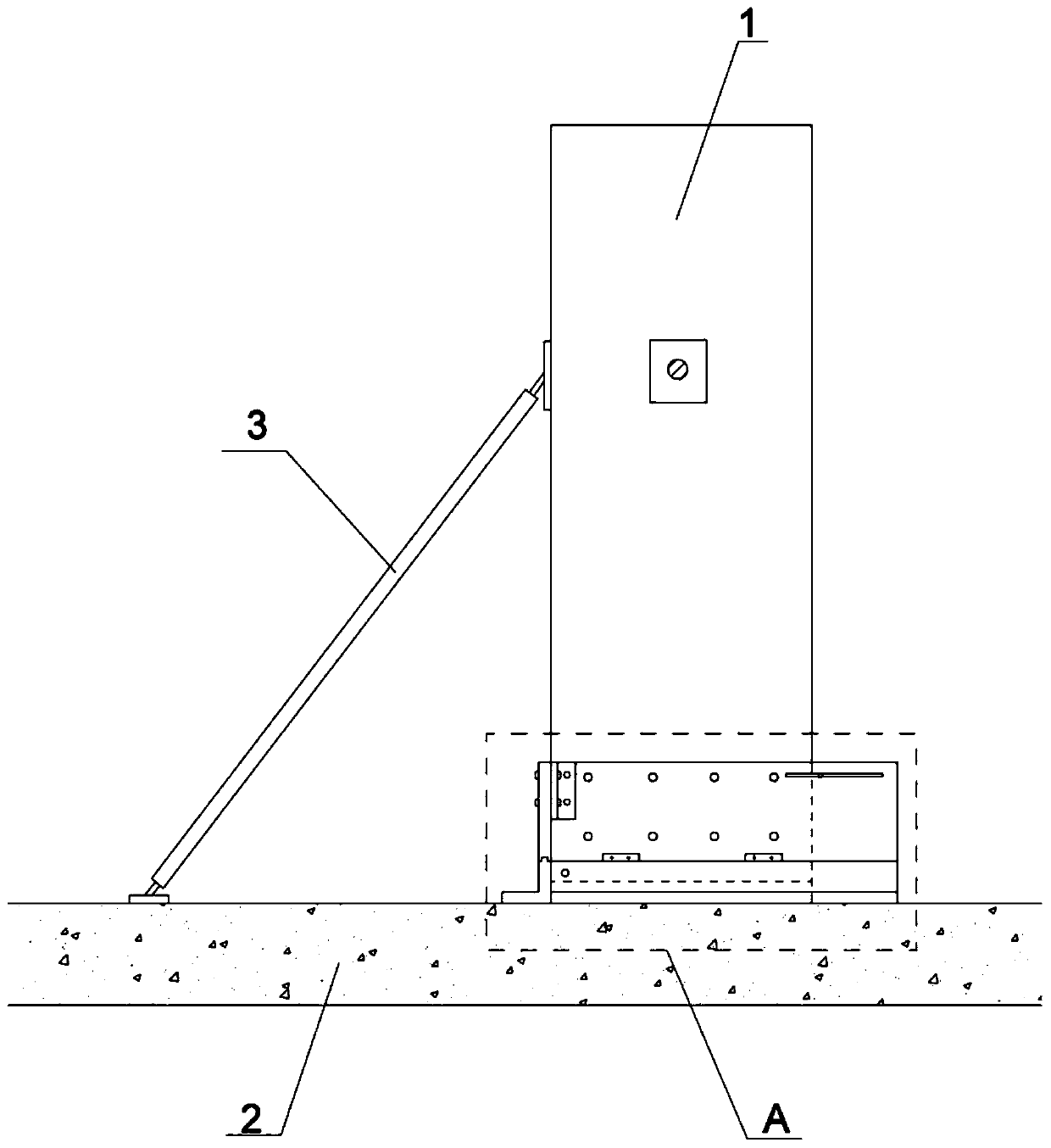

[0028] Such as figure 1 As shown, the temporary fixing device for the prefabricated column of the prefabricated frame structure in this embodiment includes a brace mechanism and a grouting mechanism.

[0029] The diagonal bracing mechanism includes a diagonal bracing rod 3. The diagonal bracing rod 3 adopts the installation and connection method of the existing prefabricated building temporary diagonal bracing, that is, one end of the diagonal bracing rod 3 is connected to the side wall of the prefabricated column 1 by a bolt, and the other end is connected by a bolt Connected to the bottom plate 2 below the prefabricated column 1 , there are two diagonal braces 3 , and the two diagonal braces 3 are respectively located on two adjacent side walls of the prefabricated column 1 .

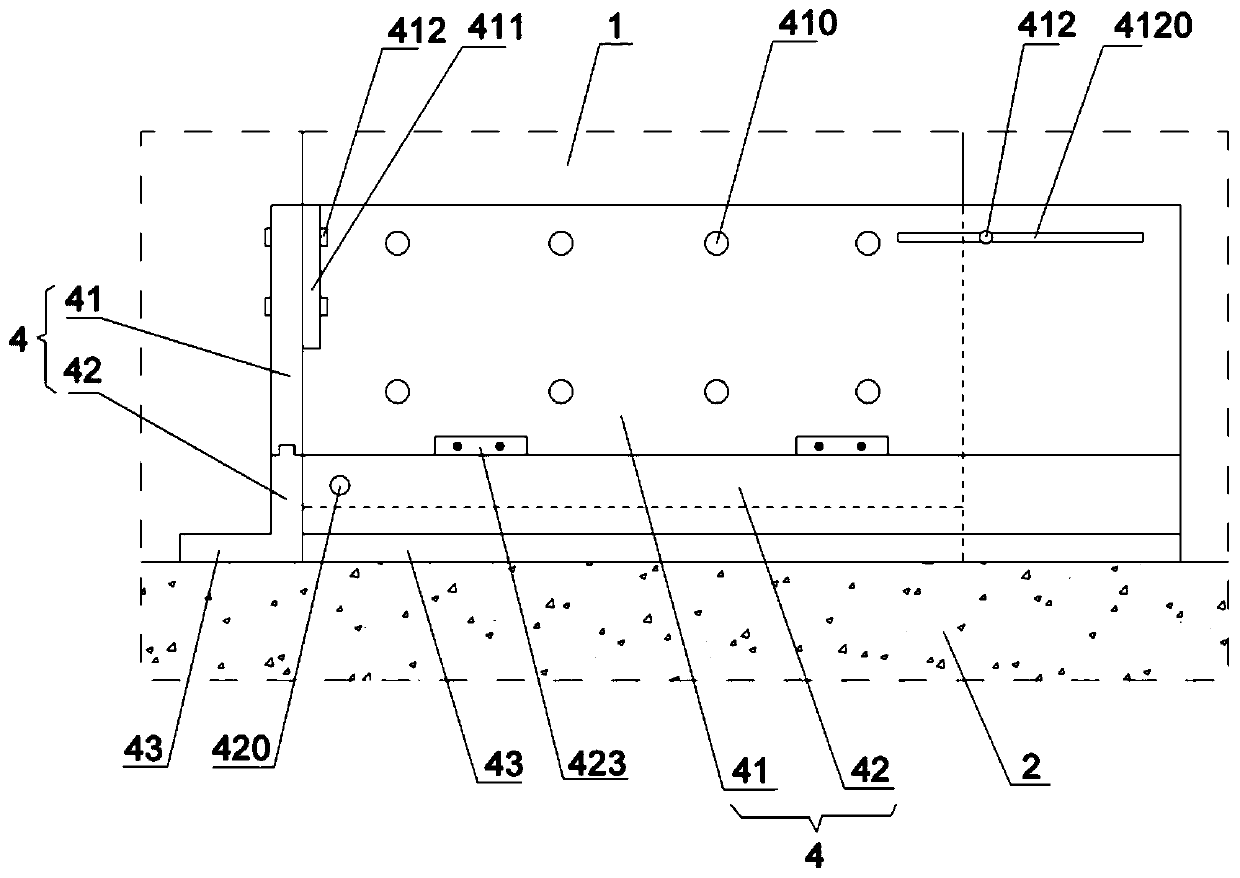

[0030] The grouting mechanism includes a plug grouting frame that can be set on the outer wall of the prefabricated column 1, and the structural combination of the plug grouting frame figure 2 with ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that in this embodiment, the locking method between the fixing plate 41 and the grouting plate 42 is different. Corresponding openings are made on the protruding strips at the top of 42, and fastening bolts 412 are used to pass through the holes on the side walls of the chute and the holes on the protruding strips to realize the connection and fixation between the fixing plate 41 and the grouting plate 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com