Underground dust removal device and operation method

A dust removal device and dust technology, applied in combination devices, safety devices, separation methods, etc., can solve problems such as large limitations, insufficient flexibility, and a large amount of foam, and achieve the effects of reducing dust, convenient transportation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

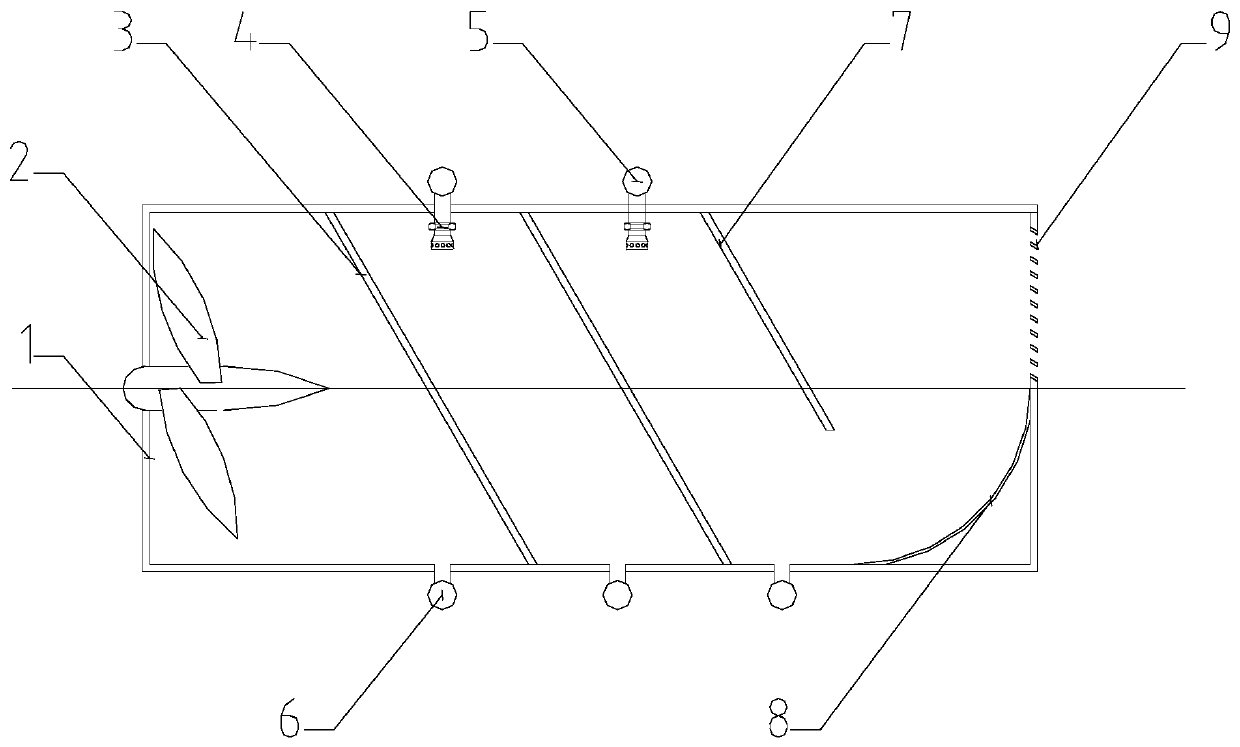

[0020] An underground dust removal device, which includes: a box body 1, a dust collection fan 2 is installed on the left side panel of the box body 1, an exhaust gas discharge grid 9 is opened on the upper side of the right side panel, and a filter cleaning device is arranged in the box body.

[0021] The filter cleaning device includes a filter screen 3, a water curtain and a cleaning nozzle 4. The filter screen 3 is fixed between the upper and lower side plates of the box body 1; the filter screen 3 is installed obliquely; the inclination direction is inclined to the left, and the inclination angle is 40 to 60° degrees; the inclination direction is 45 degrees. The water curtain and the cleaning nozzle 4 are fixed on the upper side plate of the box body 1, and are located at the top of the filter screen 3; the filter cleaning device has two sets; they are respectively installed in the box body in order.

[0022] Exhaust flow deflection baffle 7 is located behind the filter cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com