Light piston, engine and automobile

A lightweight, piston technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems that cannot meet the lightweight design requirements of pistons, and the weight of pistons is large, so as to reduce friction loss and reduce piston weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

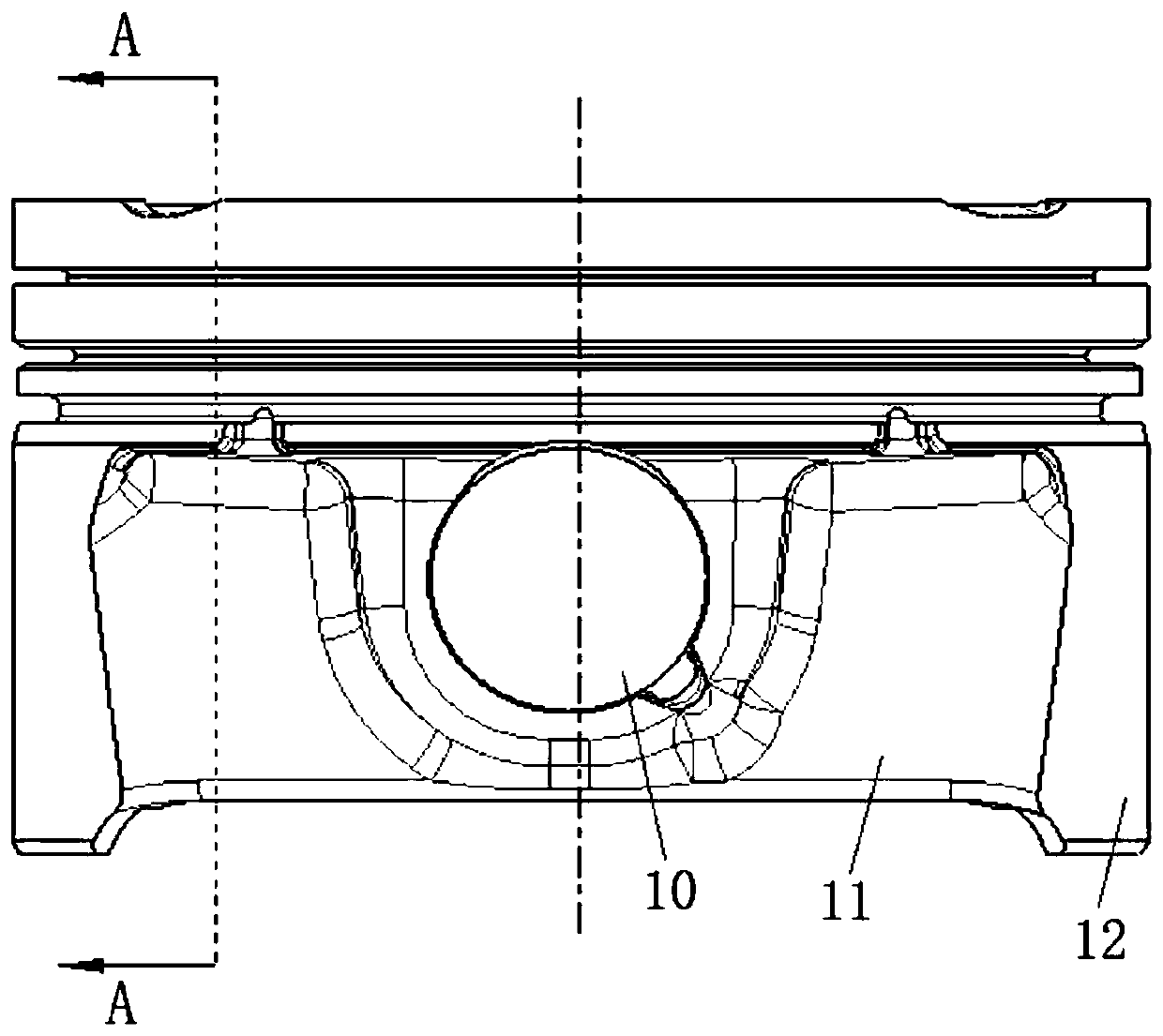

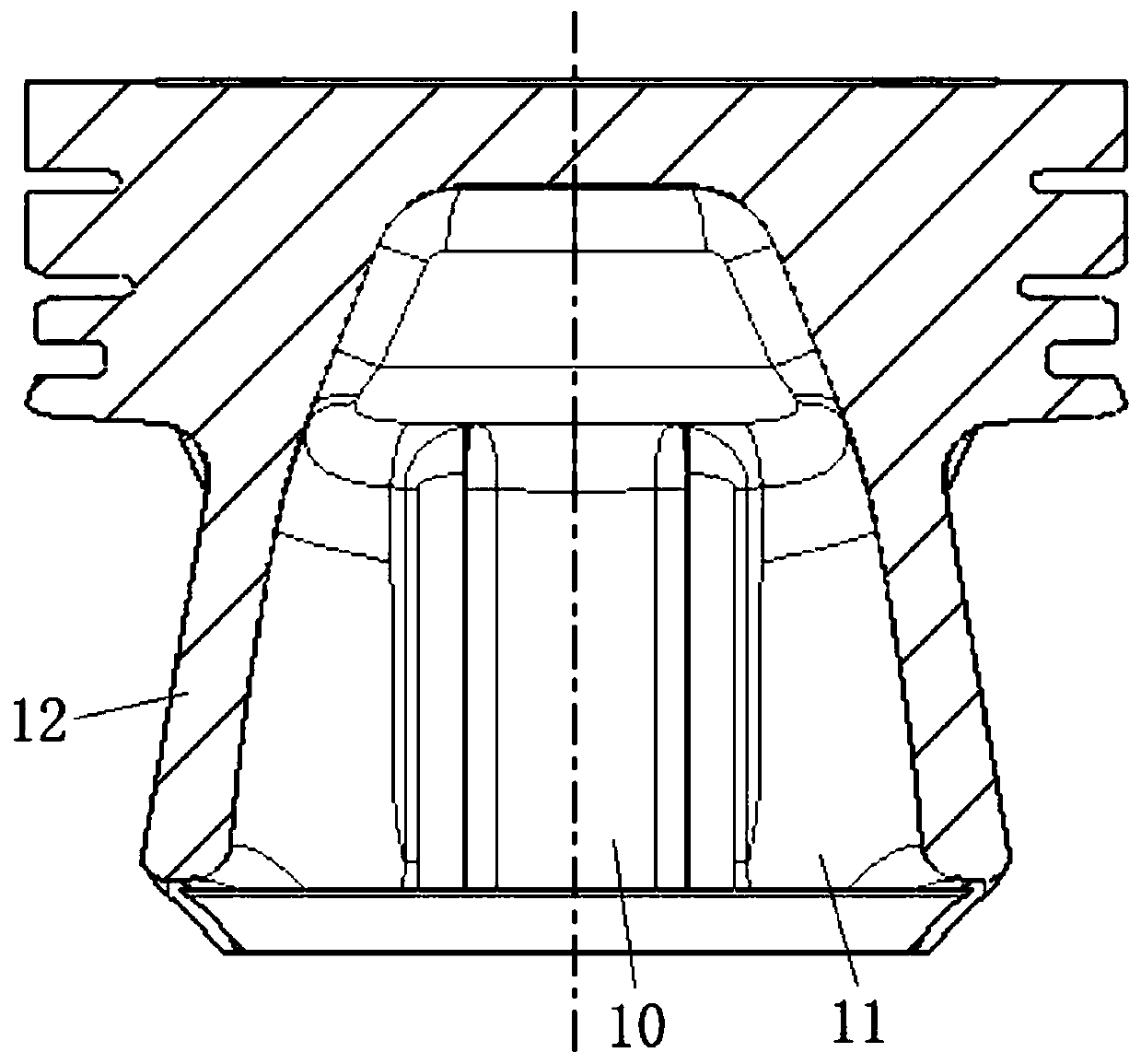

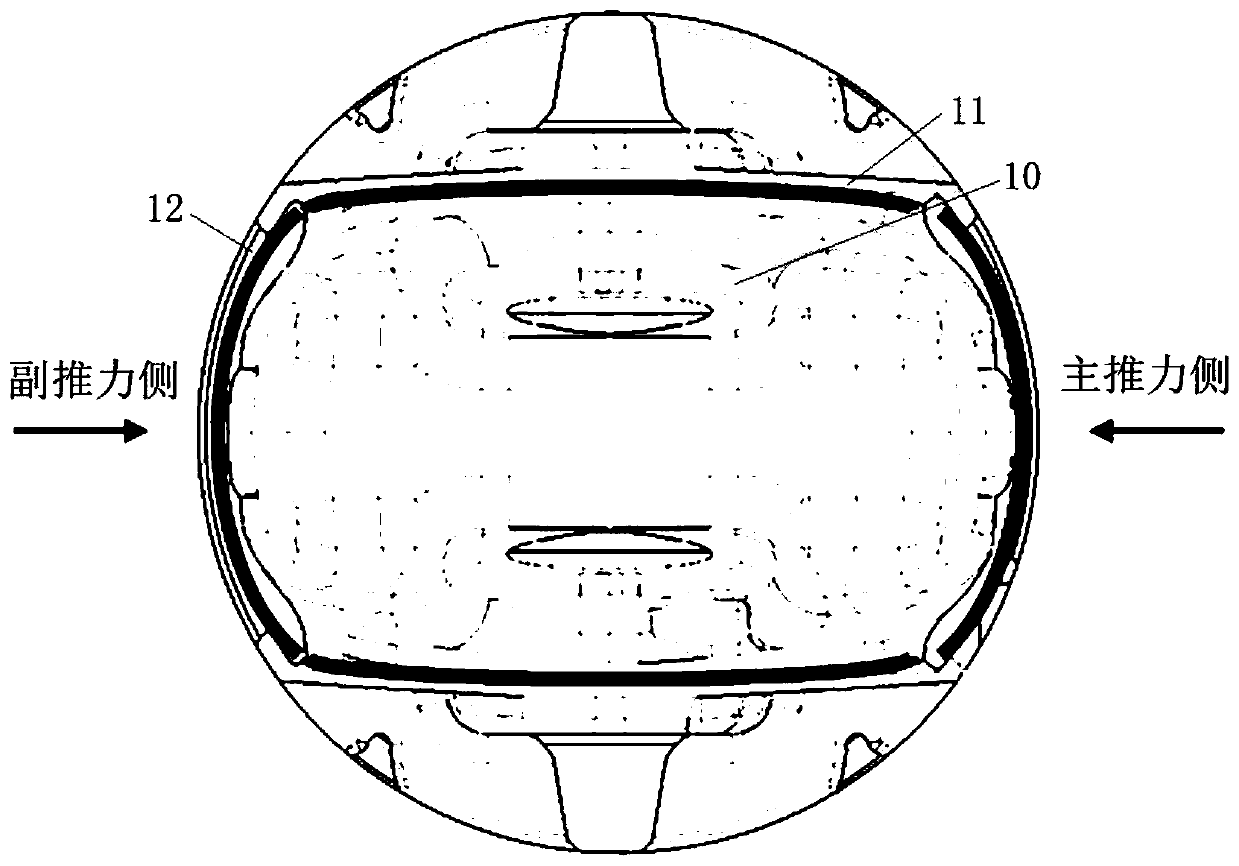

[0034] Embodiment one, see Figure 4 , Figure 5 with Figure 7 , the lightweight piston shown includes a piston head 1, a main thrust side skirt 2 and an auxiliary thrust side skirt 3, and the main and auxiliary thrust side skirts are connected by piston surface windows 4 on both sides. A pin seat 5 is arranged on the piston surface window portion 4, and the piston surface window portions 4 on both sides are arranged symmetrically along the front-rear direction, and the piston surface window portion 4 on one side includes a main thrust side window wall 41 connected with the main thrust side skirt portion 2 And the auxiliary thrust side window wall 42 connected with the auxiliary thrust side skirt 3, the main thrust side window wall 41 is a straight plane with equal wall thickness, and the main thrust side window wall thickness a 1 is 3.2mm, the angle α between the plane where the main thrust side window wall is located and the vertical direction 2 is 30°; the auxiliary thr...

Embodiment 2

[0041] Embodiment 2, a lightweight piston, its structure is the same as that of Embodiment 1, and its size parameters are:

[0042] Angle α between the lower part of the inner surface of the pin seat and the vertical plane 1 is 15°; the angle α between the plane where the main and auxiliary thrust side window walls are located and the vertical direction 2 is 30°; the angle α between the inner surface of the piston head and the outer surface of the window wall 3 is 3°.

[0043] Transverse radius R of main and auxiliary thrust side window walls 1 90mm, transition arc radius R 2 is 13mm, the radius R of the inner surface of the skirt on the main thrust side 3 is 18mm, the radius R of the inner surface of the skirt on the auxiliary thrust side 4 is 16mm, the radius of curvature R of the upper curved surface on the inner surface of the pin seat 5 52mm, pit rounding radius R 6 is 3mm, the longitudinal radius R of the main and auxiliary thrust side window wall stiffeners 7 40...

Embodiment 3

[0045] Embodiment 3, a lightweight piston, its structure is the same as that of Embodiment 1, and its size parameters are:

[0046] Angle α between the lower part of the inner surface of the pin seat and the vertical plane 1 is 13°; the angle α between the plane where the main and auxiliary thrust side window walls are located and the vertical direction 2 is 25°; the angle α between the inner surface of the piston head and the outer surface of the window wall 3 is 5°.

[0047] Transverse radius R of main and auxiliary thrust side window walls 1 is 100mm, the transition arc radius R 2 is 15mm, the radius R of the inner surface of the skirt on the main thrust side 3 is 16mm, the radius R of the inner surface of the skirt on the auxiliary thrust side 4 is 14mm, the radius of curvature R of the upper curved surface on the inner surface of the pin seat 5 55mm, pit rounding radius R 6 is 2mm, the longitudinal radius R of the main and auxiliary thrust side window wall stiffene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com