Engine piston, engine, hand-held tool, and method of manufacturing engine piston

A technology of hand-held tools and pistons, which is applied in the field of hand-held tools and manufacturing engine pistons, can solve the problems of weight reduction and problems of pistons, and achieve the effect of weight reduction of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Aspects of the invention will now be described more fully. Like numbers refer to like elements throughout. Well-known functions or constructions are not necessarily described in detail for brevity and / or clarity.

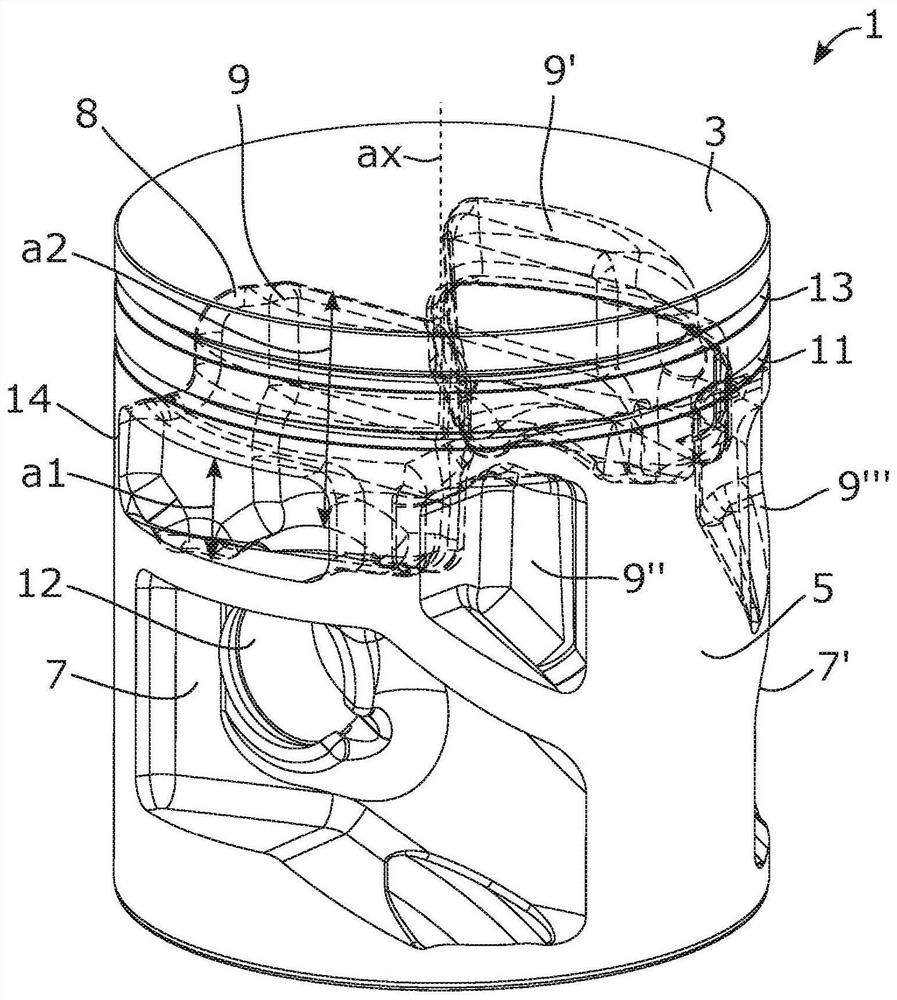

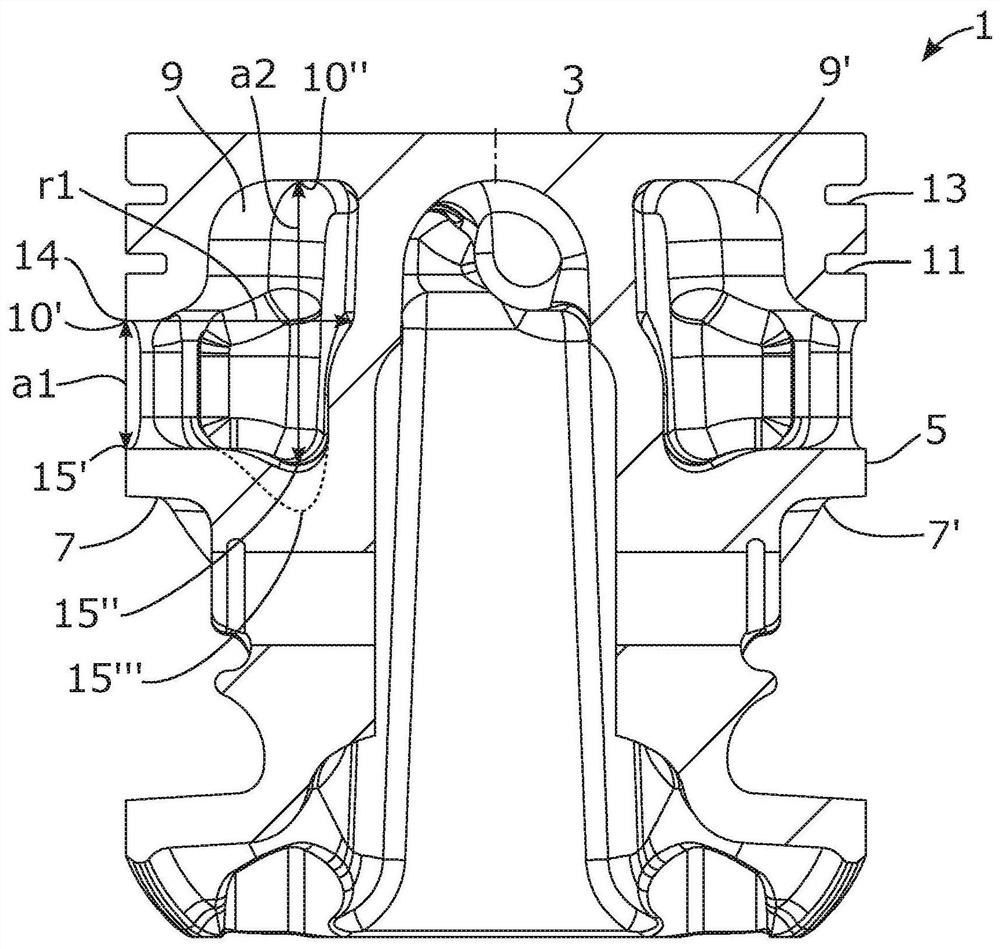

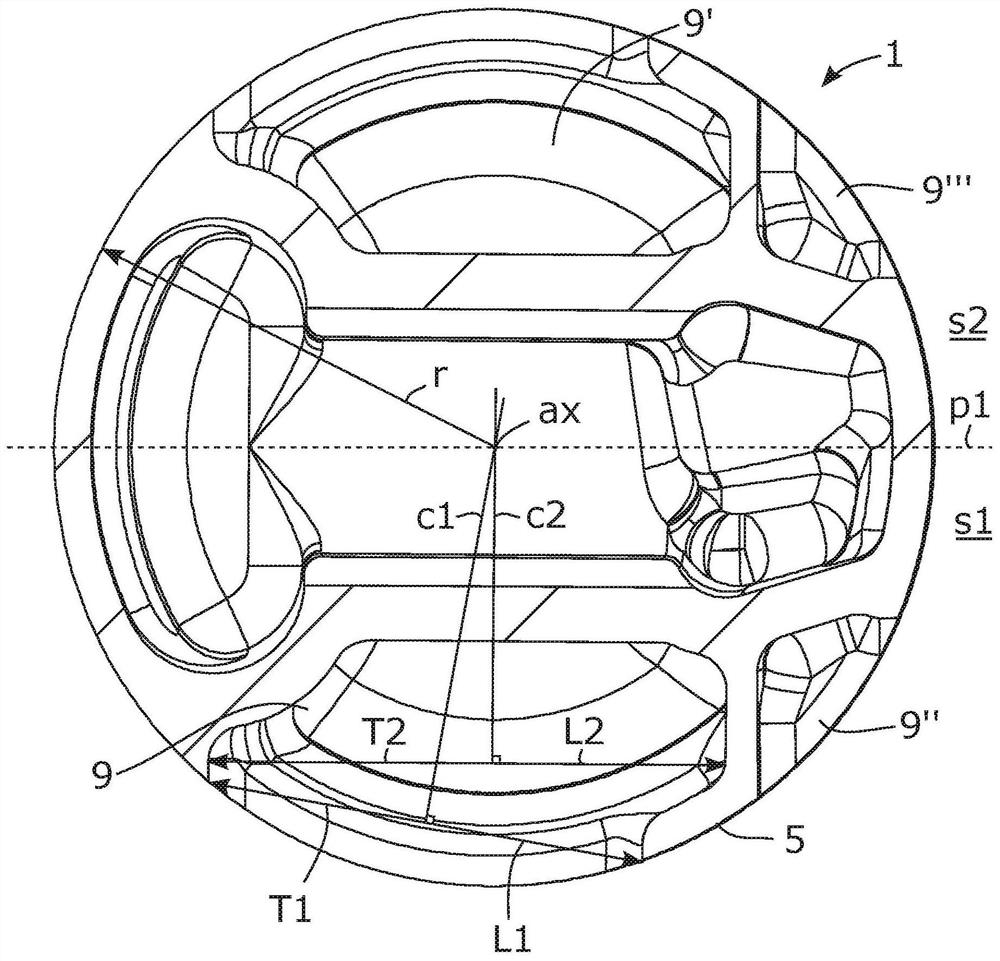

[0075] figure 1 A perspective view of a two-stroke engine piston 1 according to some embodiments is shown. For the sake of brevity and clarity, the two-stroke engine piston 1 is referred to as "piston 1" in some places herein. Piston 1 includes a piston crown 3 . When the piston 1 is arranged in the engine cylinder, the piston top 3 is arranged facing the cylinder head of the engine cylinder of the two-stroke engine. The piston crown 3 is arranged to define a combustion chamber together with the cylinder walls of the engine cylinder. Thus, the piston crown 3 is arranged to be in contact with hot combustion gases during the power stroke of the engine comprising the piston 1 . Furthermore, the piston 1 comprises a cylindrical mantle surface 5 . The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com